Position monitoring device for grounding handcart of switch cabinet

A monitoring device and switchgear technology, applied in switchgear, switchgear parts, pull-out switchgear, etc., can solve the problems of fuse handcart conflict, arc fire, grounding short circuit, etc. Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

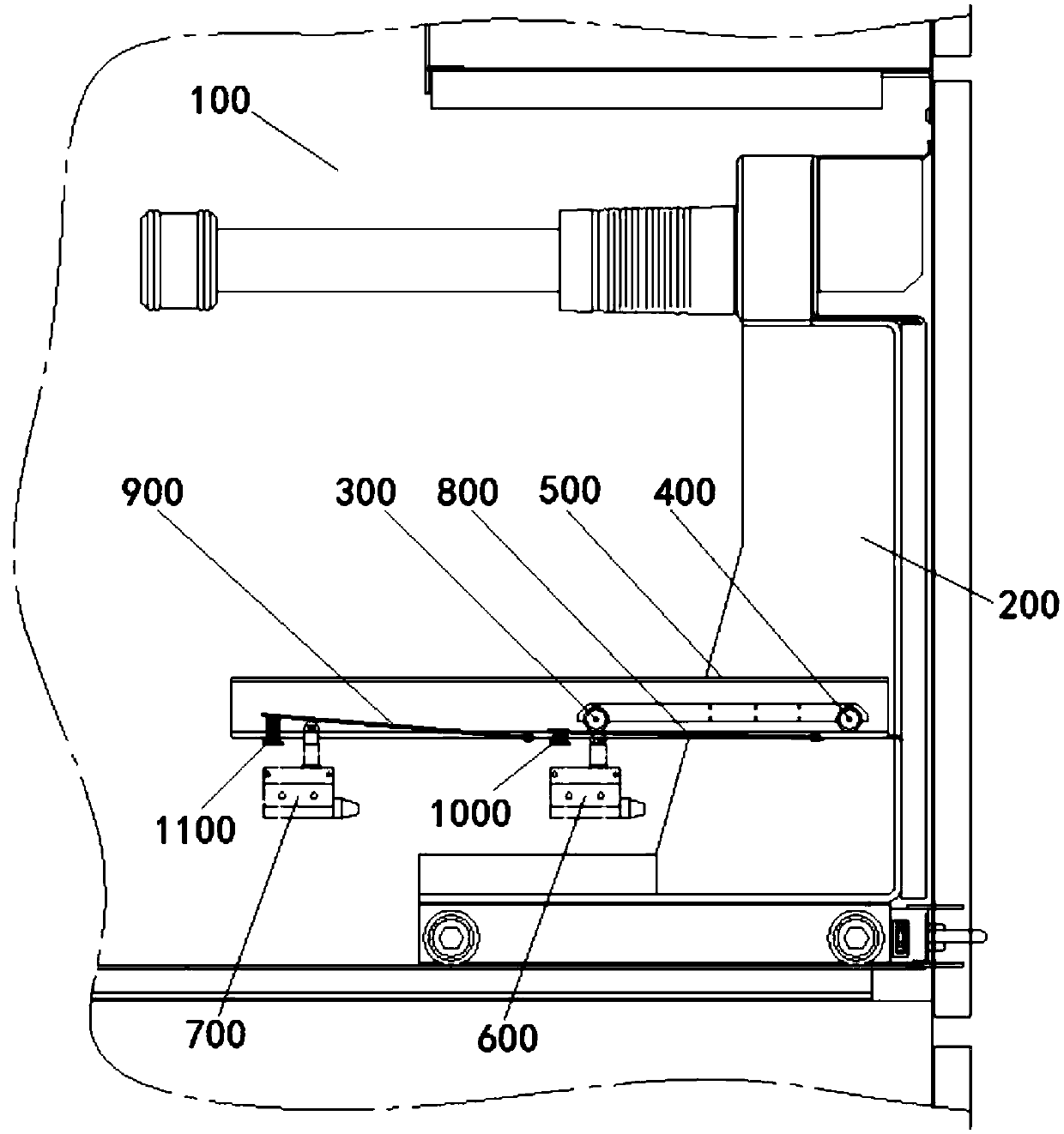

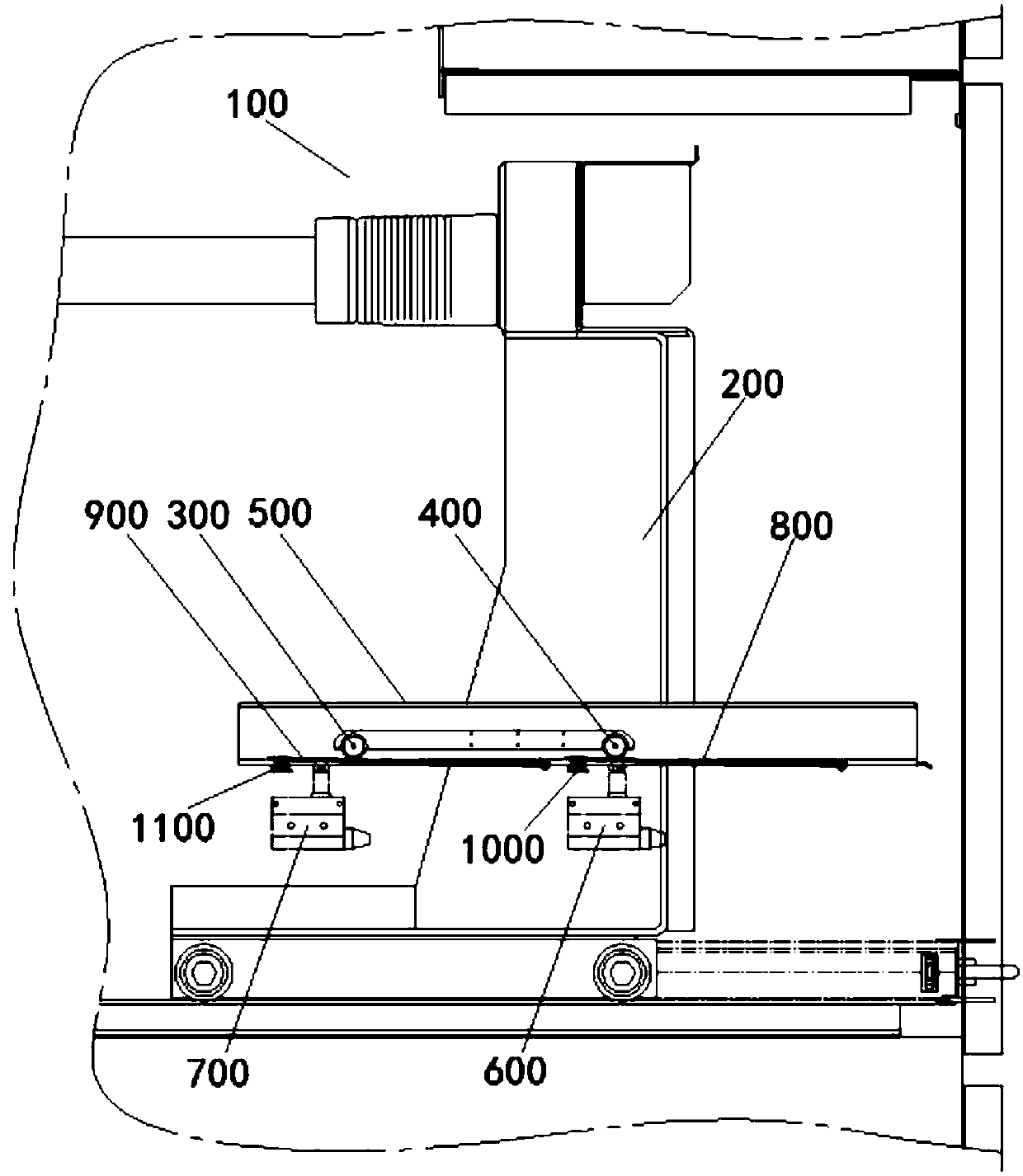

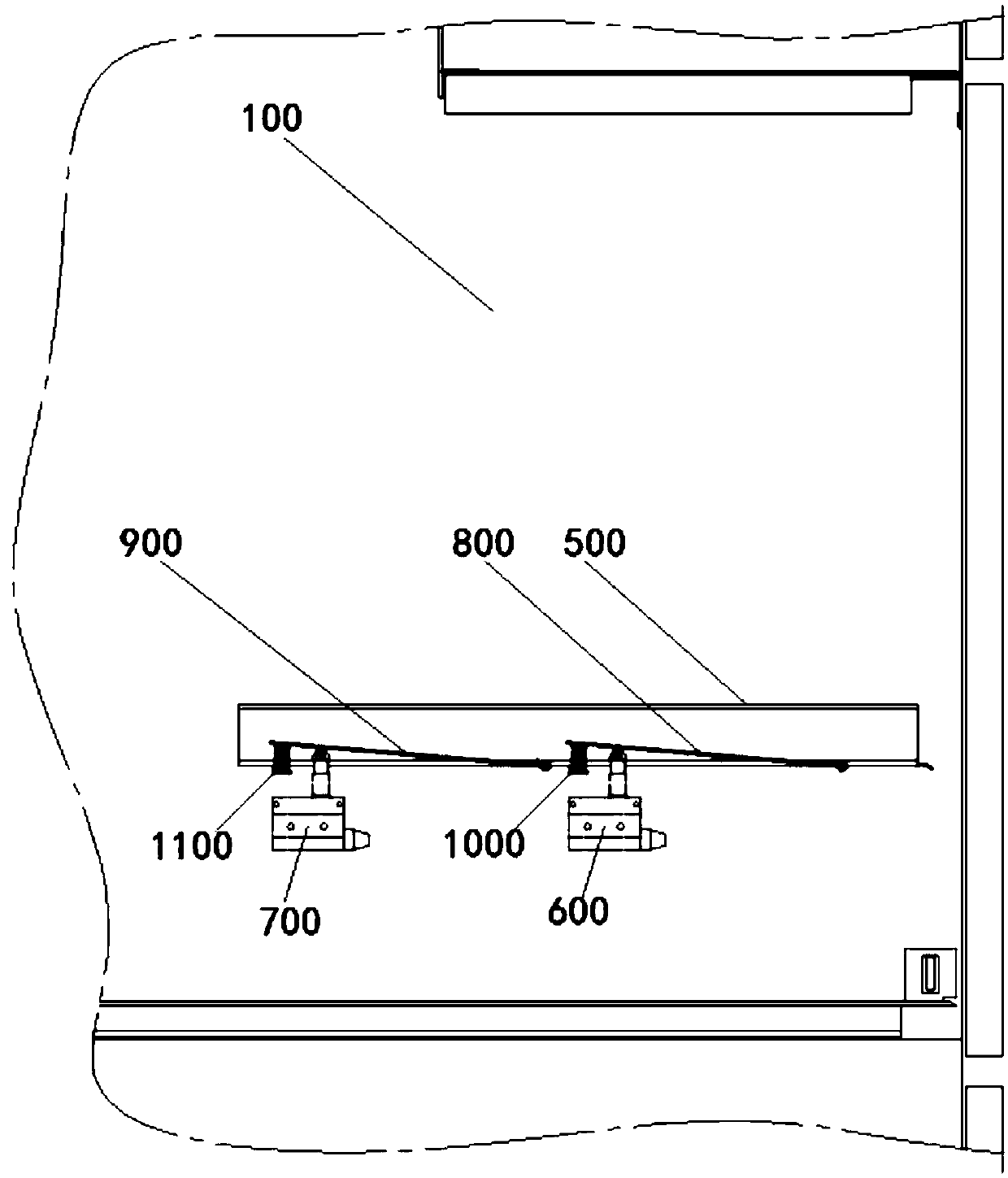

[0017] See Figure 1 to Figure 4 As shown, the figure shows a position monitoring device for a switch cabinet grounding handcart, which includes a switch compartment 100 in which a grounding handcart 200 and a pulley guide rail 500 are provided.

[0018] A front pushing pulley 300 is provided on the front end of the grounding handcart 200 on the pulley guide 500, and a rear pushing pulley 400 is provided on the rear end of the grounding handcart 200 on the pulley guide 500; on the pulley guide 500 A front pressing bar 800 is articulated below the front pressing pulley 300, and a front return spring 1000 is arranged between one end of the front pressing bar 800 and the pulley guide rail 500; a state travel switch 600 is arranged at the front end of the pulley guide 500 below the front pressing bar 800 , Used to monitor whether the grounded handcart 200 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com