Snake breeding chamber

A technology of snake house and snake house body, applied in the field of snake house, can solve the problems of habitat destruction of wild snakes, poisoning of humans and animals, fewer snakes, etc., and achieve the effect of improving the living environment of snakes and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

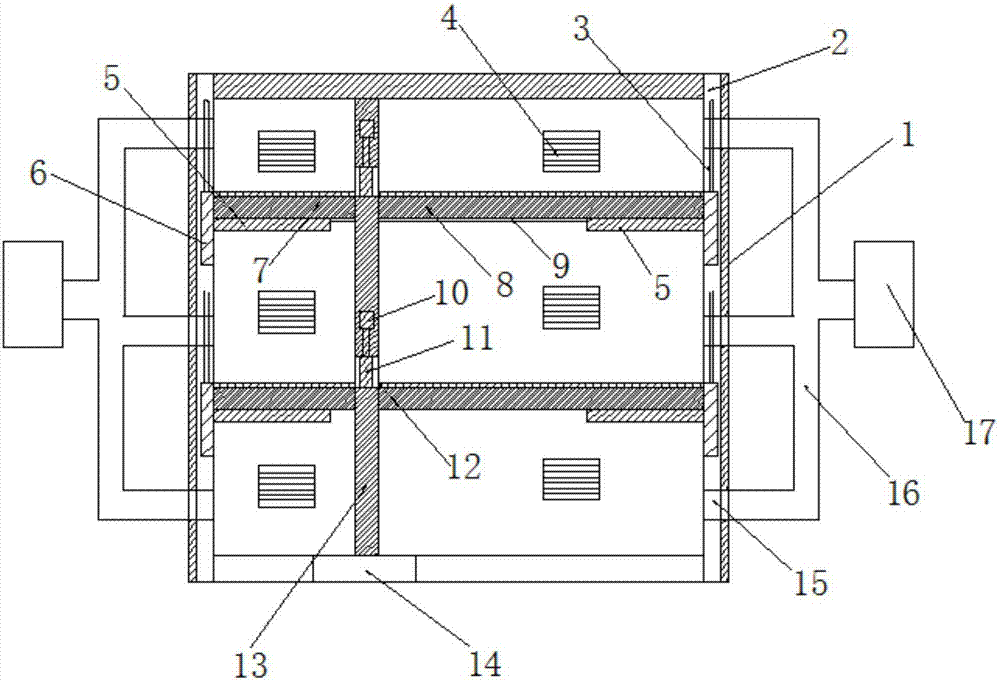

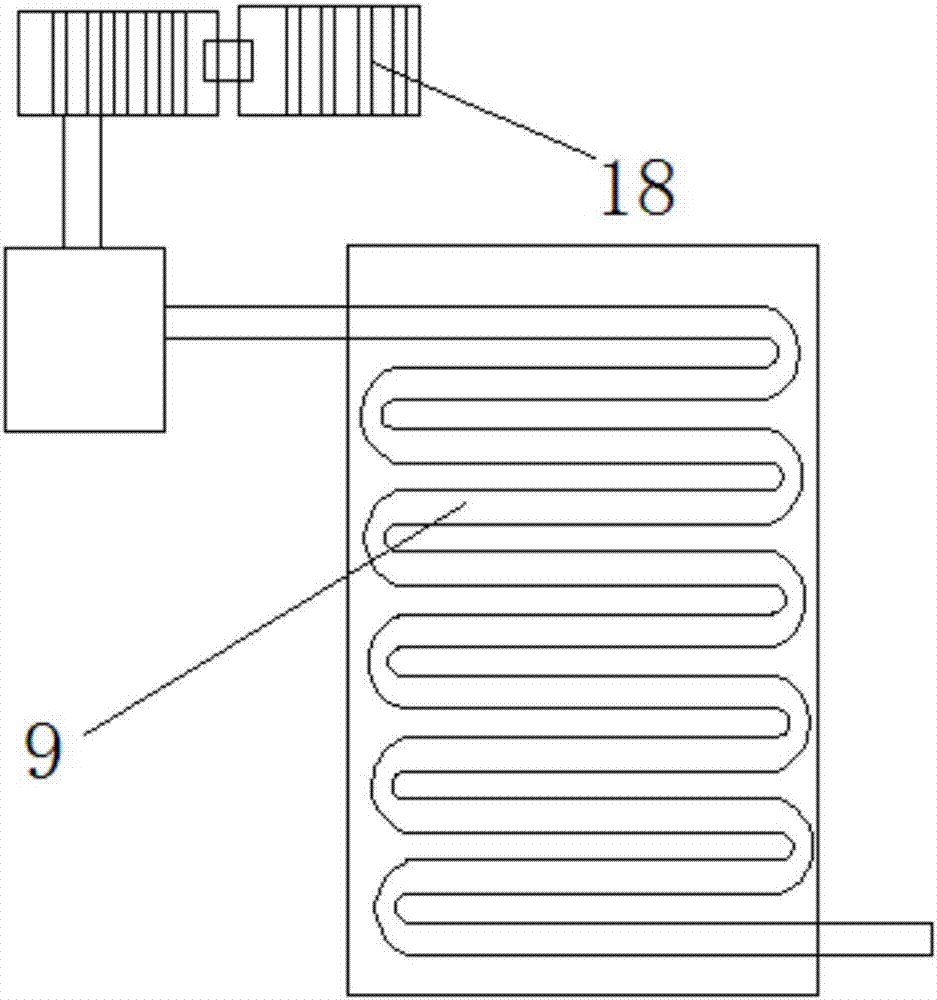

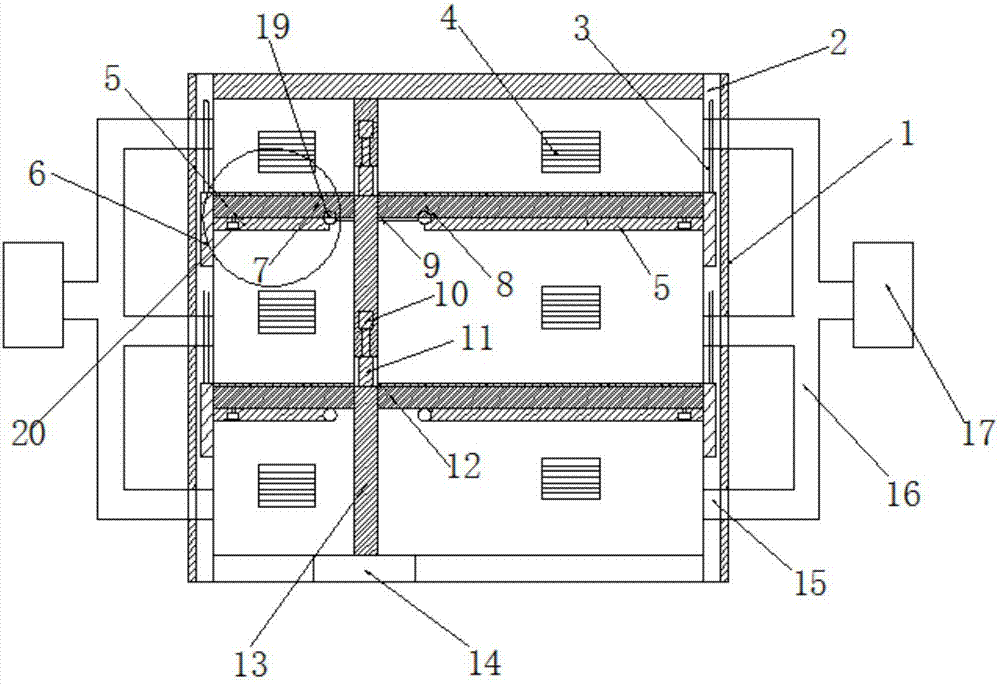

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0025] A snake breeding room, the snake breeding room includes a snake breeding room body 1 with a rectangular cross-section, the lower end of the snake breeding room body 1 is provided with a sewage discharge channel 14 for sewage discharge, and more than one The placement boards for the layers of the snake-raising room body 1 are provided with a blocking board 13 for the partition of the snake-raising room body 1 in the vertical direction inside the snake-raising room body 1. 1 is divided into multiple layers, and the overall area of the snake-raising room 1 is optimized, and a certain number of snakes are cultivated on each floor at the same time, so that the total number of snakes in the whole snake-raising room 1 is equal to the number in the traditional snake-raising room. The same,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com