Semi-automatic strawberry harvesting and packaging equipment and its strawberry packaging bag

A technology of automatic packaging and packaging equipment, applied in the field of agricultural machinery, can solve the problems of high labor intensity, low efficiency, inconsistent total weight of strawberries, etc., to increase daily output, reduce labor intensity, and meet diversified sales needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

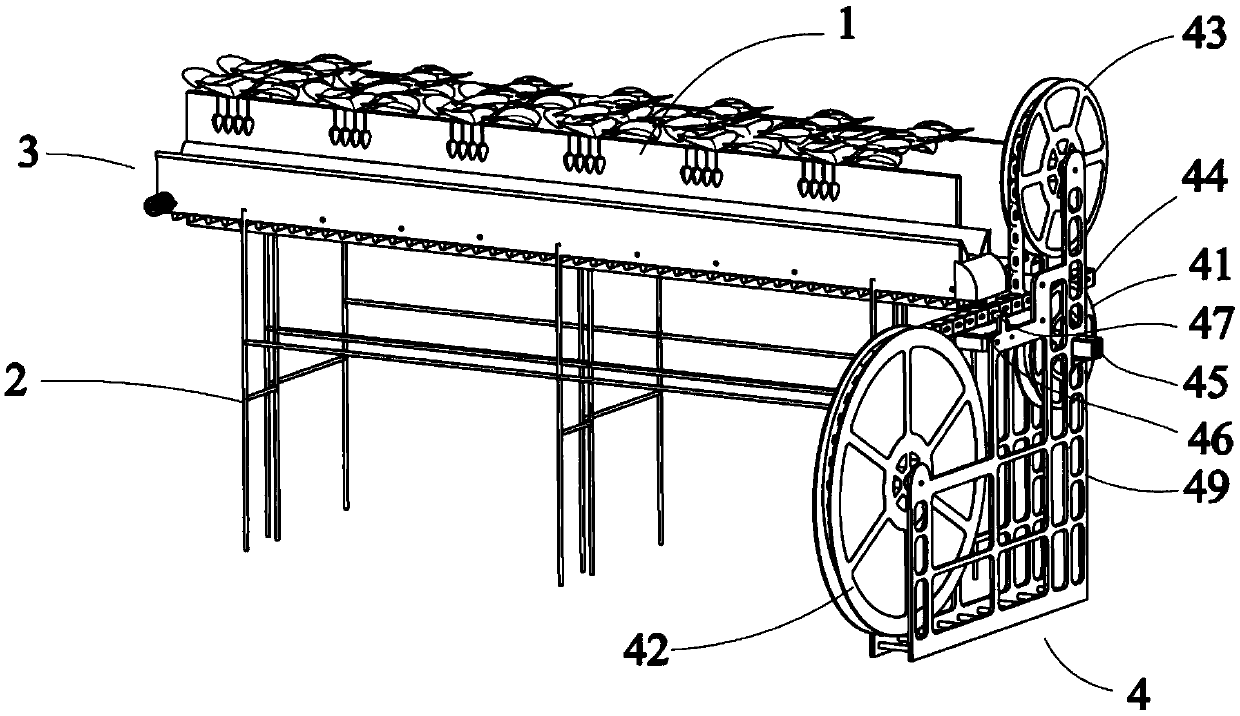

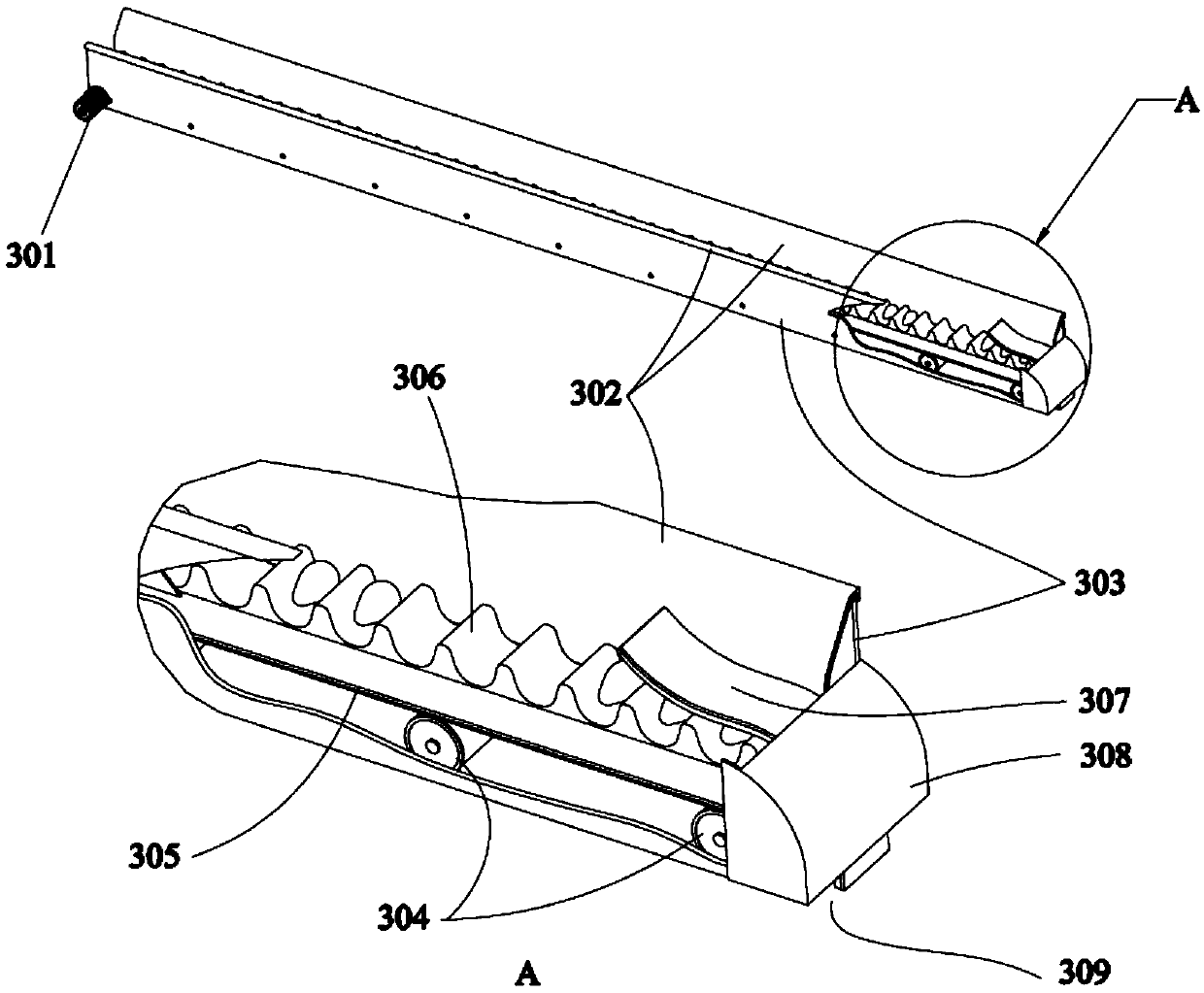

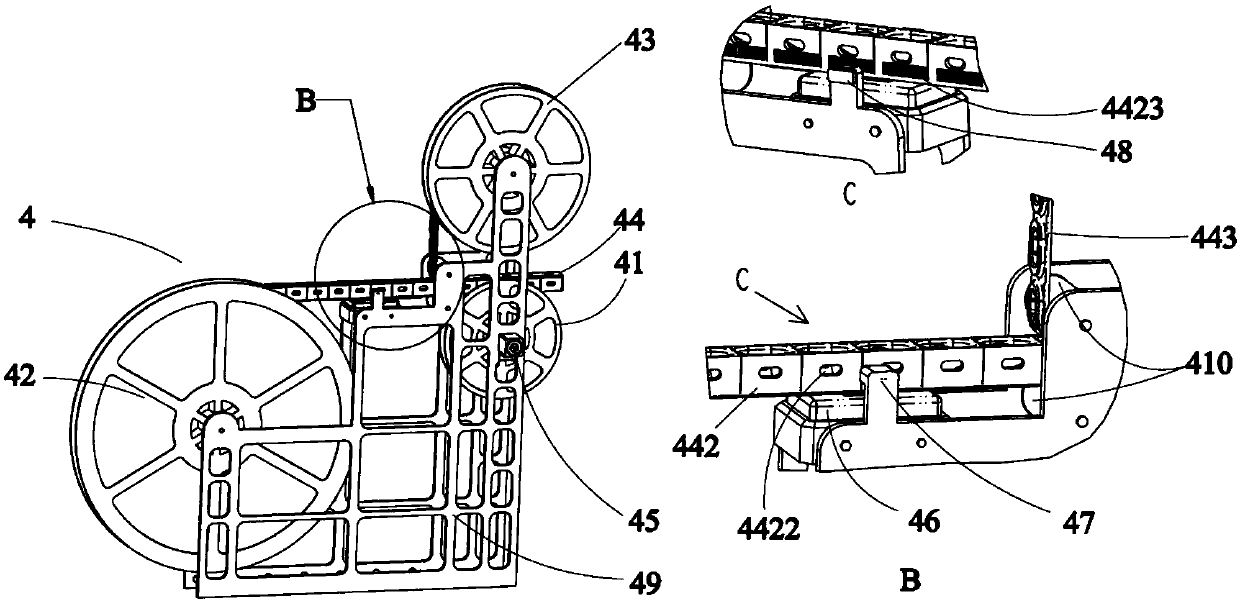

[0011] like figure 1 , 2 , 3, 4, and 5 shown, the present embodiment is made up of strawberry delivery tank 3 and automatic packaging system 4 ( figure 1 ), wherein the strawberry delivery tank 3 is made up of a conveyor belt motor 301, a side sponge 302, a delivery tank frame 303, a roller 304, a conveyor belt 305, a conveyor belt sponge 306, an end cover sponge 307 and a conveyor belt end cover 308 ( figure 2 ); the automatic packaging system 4 is composed of the rubber wheel 41 at the bottom of the packaging bag, the lower box wheel 42 of the packaging bag, the upper cover wheel 43 of the packaging bag, the packaging system drive motor 45, the weighing sensor 46, the reflective photoelectric sensor 47, the barcode scanner 48, Packaging system frame 49, packaging bag guide wheel 410 and strawberry packaging bar 44 form ( image 3 ); it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com