Protective film for notebook computer screen

A screen protective film and notebook computer technology, which is applied in the field of computer screens, can solve problems affecting the life of the display screen, etc., and achieve the effects of prolonging the service life, using it for a long time, and increasing the toughness and firmness of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

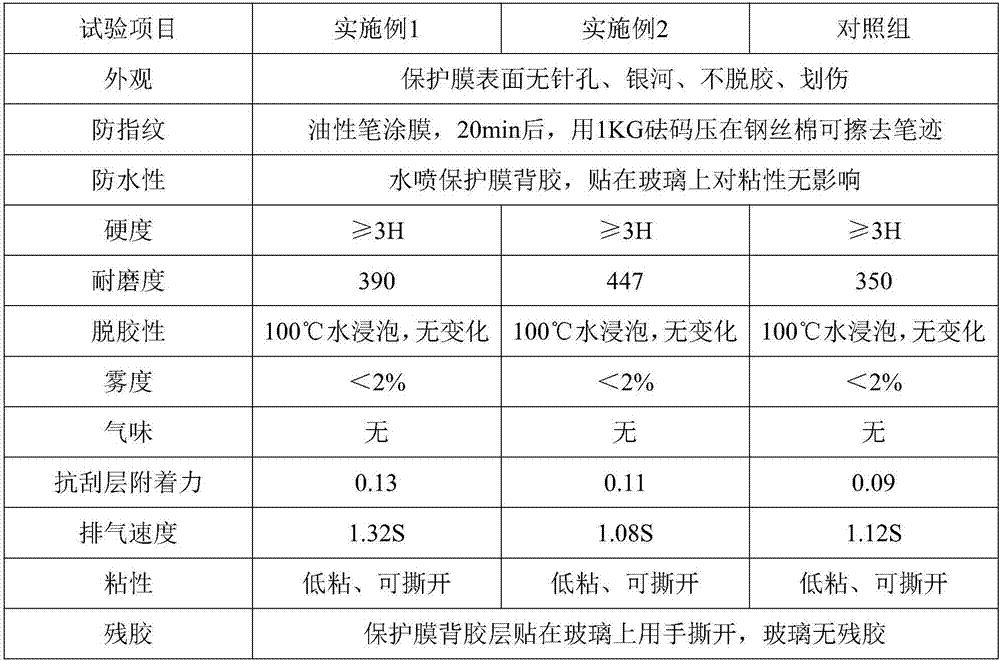

Examples

Embodiment 1

[0022] A kind of notebook computer screen protector is made of the following raw material components in parts by weight:

[0023] 4 parts of low density polyethylene, 2 parts of sodium alginate, 8 parts of polyglycerol fatty acid ester, 10 parts of monoglyceride laurate, 6 parts of polymerized alumina, 10 parts of terpene resin, 5 parts of zeolite powder, 7 parts of gelatin, 12 parts of ethanol, 25 parts of deionized water, 8 parts of film-forming aids, 10 parts of nano-ferric oxide microspheres, 3 parts of silicon dioxide powder, 4 parts of beeswax matrix, 6 parts of butyl acrylate, polytetrafluoroethylene 13 parts, silane γ-methacryloxypropyltrimethoxysilane 5 parts.

[0024] The preparation method of the polymerized alumina: add 6 parts of molten alumina into the reaction kettle, start stirring, slowly add quantitative 4 parts of glutaraldehyde aqueous solution, raise the temperature to 45°C, add polyvinyl alcohol, and heat up to 80°C within 30 minutes, Insulate for 2 hour...

Embodiment 2

[0034] A kind of notebook computer screen protector is made of the following raw material components in parts by weight:

[0035] 3 parts of low-density polyethylene, 3 parts of sodium alginate, 8 parts of polyglycerol fatty acid ester, 9 parts of monoglyceride laurate, 10 parts of polymerized aluminum oxide, 6 parts of terpene resin, 4 parts of zeolite powder, 5 parts of gelatin, 10 parts of ethanol, 30 parts of deionized water, 9 parts of film-forming aids, 7 parts of nano-ferric oxide microspheres, 8 parts of silicon dioxide powder, 4 parts of beeswax matrix, 4.5 parts of butyl acrylate, polytetrafluoroethylene 11 parts, 7 parts of silane γ-methacryloxypropyl trimethoxysilane.

[0036] The preparation method of the polymerized alumina: add 10 parts of molten alumina into the reaction kettle, start stirring, slowly add quantitative 3 parts of glutaraldehyde aqueous solution, raise the temperature to 40°C and add polyvinyl alcohol, heat up to 60°C within 30 minutes, Insulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com