Flap valve

A technology for flapping door seat and door cover, applied in the field of flapping door, can solve the problems of unsatisfactory counterweight effect, difficulty in opening flapping door, low impact force of water flow, etc., to improve service life, facilitate liquid injection and discharge, Impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

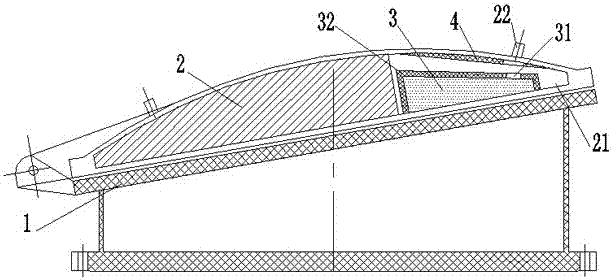

[0018] The present invention comprises a flapper seat 1 and a flapper cover 2 hinged on the flapper seat 1, the flapper cover 2 is obliquely arranged on the flapper seat 1, and the lower end of the flapper cover 2 is a hinged end;

[0019] The upper end of the flap door cover 2 is provided with a cavity 21, and a counterweight device 3 is provided in the cavity 21, and the counterweight device 3 is supported by the bottom surface of the cavity 21, and the counterweight device 3 is incompatible with The top surfaces of the cavities 21 are in contact.

[0020] The counterweight device 3 is a liquid storage tank, and the liquid medium is stored in the liquid storage tank.

[0021] The top surface of the cavity 21 is provided with an elastic layer 4 on the upper part of the counterweight device 3 .

[0022] The counterweight device 3 is provided with a liquid injection port 31 , and the flap cover 2 is provided with a liquid inlet 22 corresponding to the liquid injection port 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com