Glass fiber-reinforced plastic underground buried pipe with fault location function

A technology of fault location and buried pipes, applied in the direction of pipes, rigid pipes, pipeline systems, etc., can solve the problems of waste of resources, untimely detection of pipeline ruptures, and accidents, etc., and achieves easy fault detection, simple wiring, maintenance and disassembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

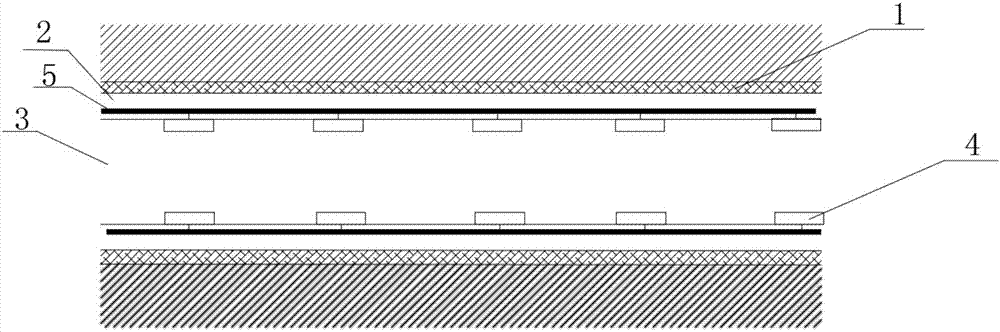

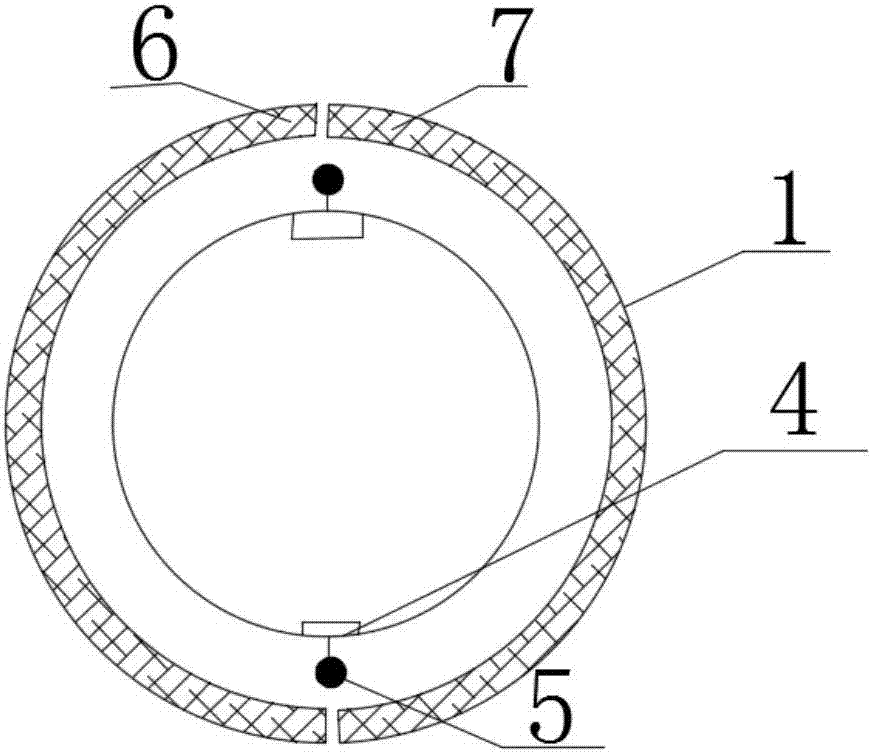

[0025] Such as figure 1 , 2 As shown, the FRP underground pipe with fault location function of the present invention includes a reinforcement layer 1, a FRP layer 2, a delivery pipeline 3, a pressure sensor 4, and a communication optical cable 5. The reinforcement layer 1 is arranged on the outermost side, and the delivery pipeline 3 is arranged In the innermost side, the FRP layer 2 is located between the reinforcement layer 1 and the conveying pipeline 3, the pressure sensor 4 is arranged inside the conveying pipeline 3, the pressure sensor 4 is connected to the communication optical cable 5, and the communication optical cable 5 is arranged in the FRP layer 2 , the number of the pressure sensors 4 is more than 2, and all the pressure sensors 4 are arranged on the inner side of the upper part and the lower part of the conveying pipeline 3, and the positions of the pressure sensors 4 on the inner side of the upper part and the inner side of the lower part are symmetrical, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com