Intelligent circular grain drying device

A drying device and intelligent technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of uneven drying, dead corners, deterioration, etc., to achieve uniform drying and realize the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

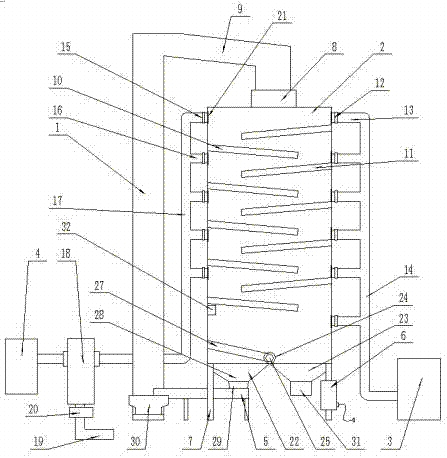

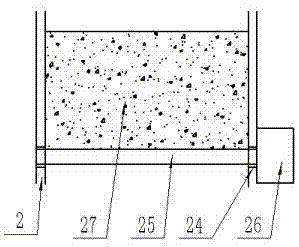

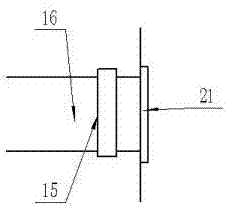

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a grain intelligent circulation drying device includes a hoist 1, a drying box 2, a heat pump 3, an exhaust fan 4, a circulation conveyor 5 and a control box 6, and the drying box 2 is fixed on the ground by a bracket 7 Above, the top of the drying box 2 has a grain inlet 8, and the top of the hoist 1 is connected to the grain inlet 8 through a discharge pipe 9. The right side of the inner cavity of the drying box 2 is provided with evenly distributed and The first group of inclined falling plates 10 arranged vertically, the left side of the inner cavity of the drying box 2 is provided with a second group of inclined falling plates 11 evenly distributed and vertically arranged, the first group of inclined falling plates 10 and the second set of inclined falling plates 11 Two groups of inclined falling plates 11 are successively fixed on both sides of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com