A rapid evaluation method for the working state of pre-bent bottom hole assembly

A bottom hole assembly and working state technology, applied in the field of oil and gas drilling, can solve the problems of reduced accuracy and unsuitable for pre-bending BHA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

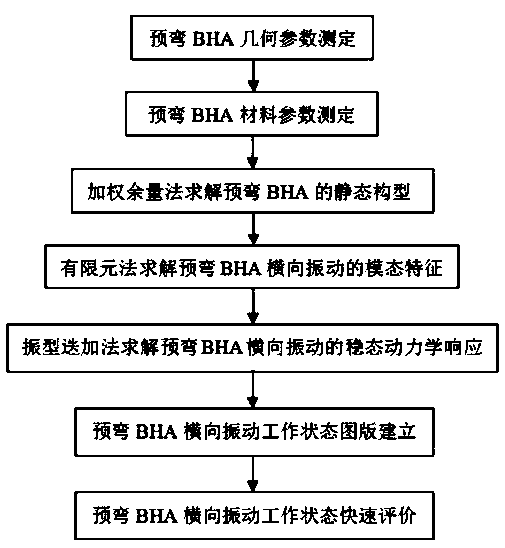

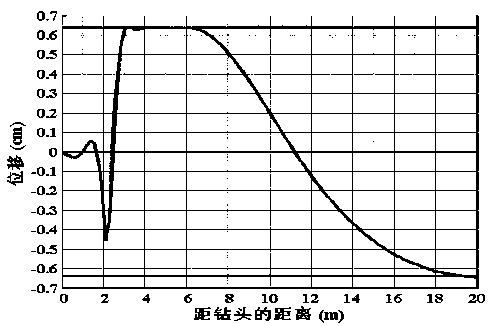

[0031] like figure 1 As shown, a rapid evaluation method for the working state of the pre-bent bottom hole assembly, combined with the weighted margin method and the finite element method, can quickly determine the working state of the lateral vibration of the pre-bending anti-deflection BHA.

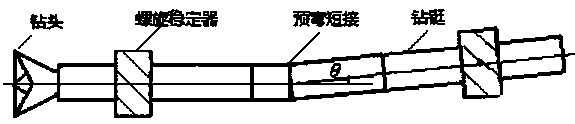

[0032] 1) Use special measuring tools such as inner diameter gauge, disc micrometer, thickness gauge, image measuring instrument, etc. to measure the pre-bending BHA (see attached figure 2 ), the main measurement results are shown in Table 1.

[0033] Table 1 Main structural parameters of pre-bent BHA

[0034]

[0035] 2) Using MTS universal testing machine, density measuring instrument and other special material testing equipment and methods, experimentally determine the mechanical parameters of the materials used in pre-bending BHA, the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com