Swing mechanism and multifunctional machine

A swing mechanism and transmission component technology, applied in the field of power tools, can solve problems such as low strength and short service life, and achieve the effects of high strength, small size, and reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

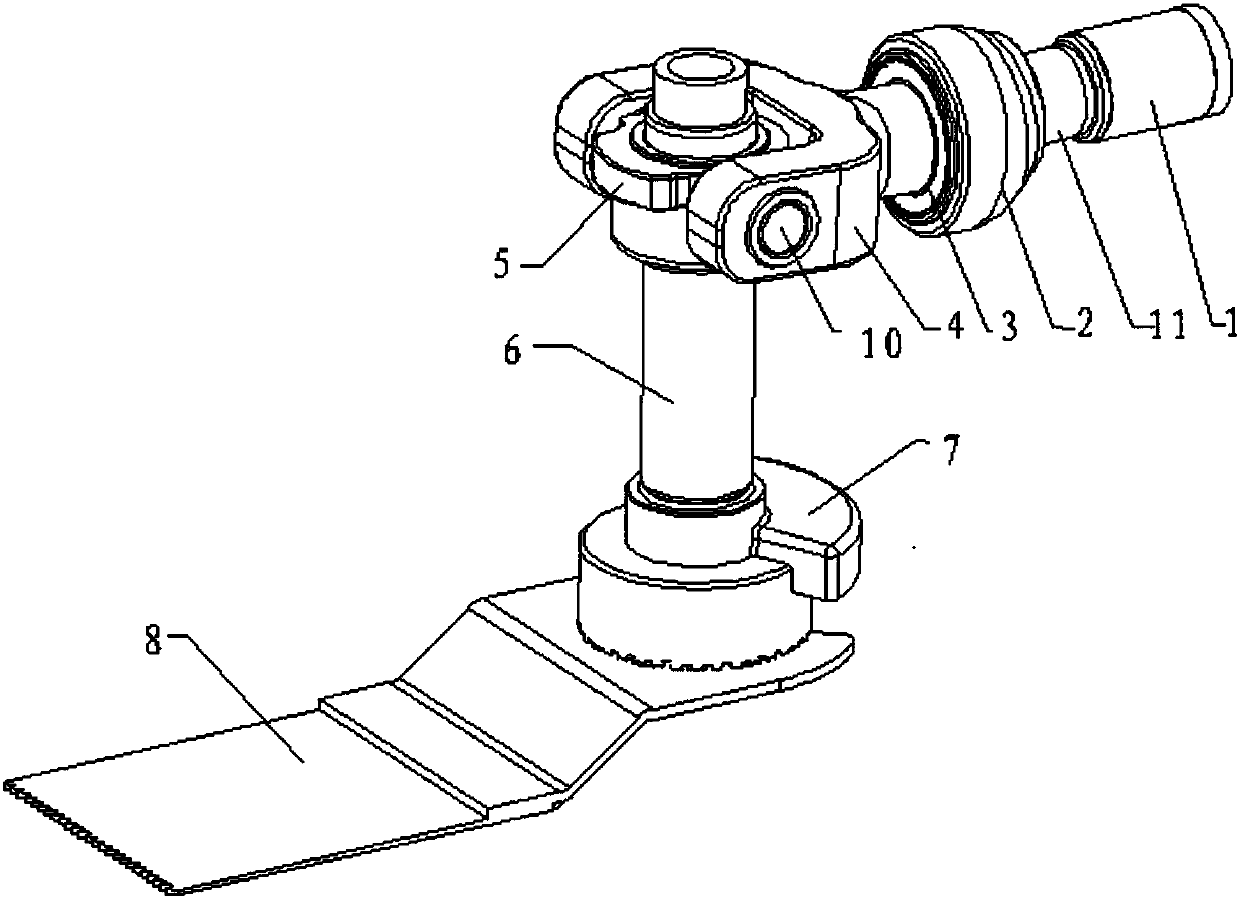

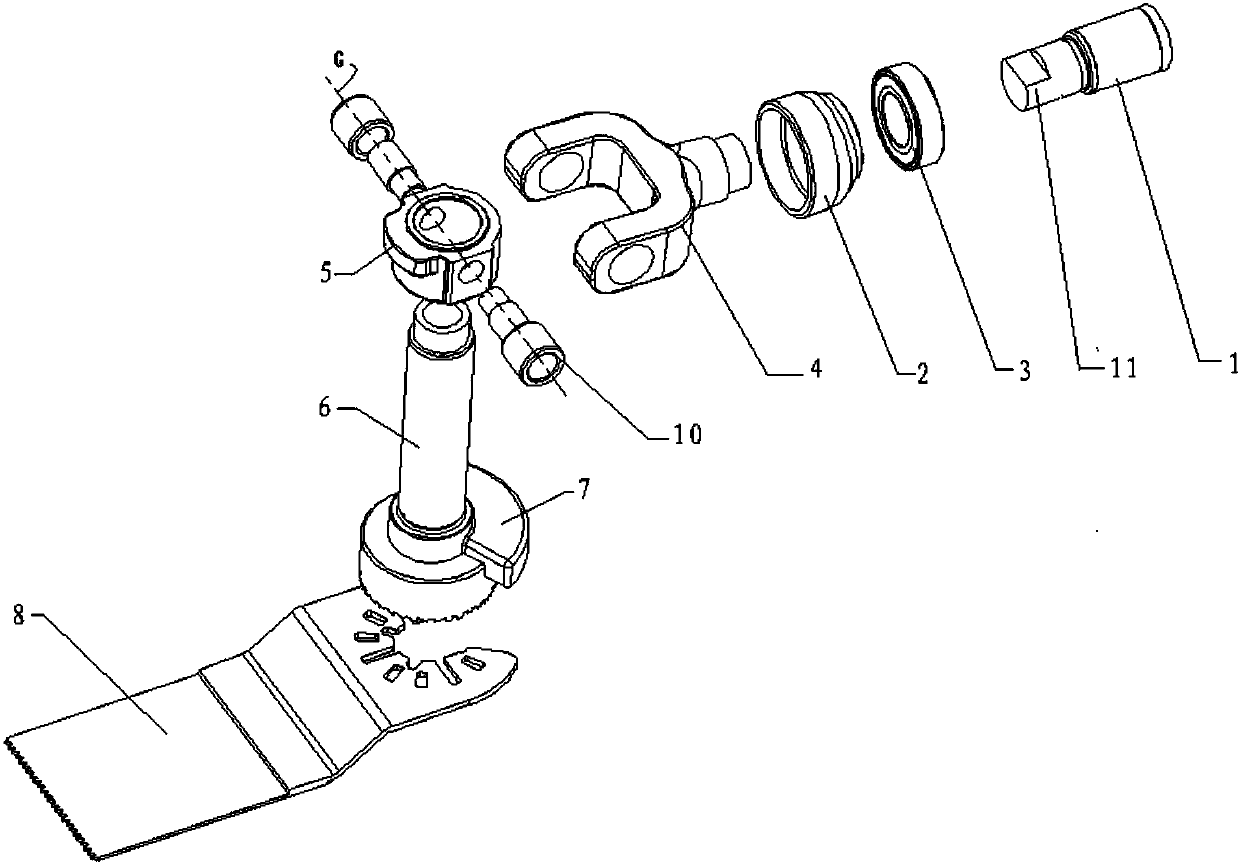

[0038] see Figure 1-3 As shown, the swing mechanism of Embodiment 1 includes

[0039] The drive shaft 1 rotates under the drive of the power structure;

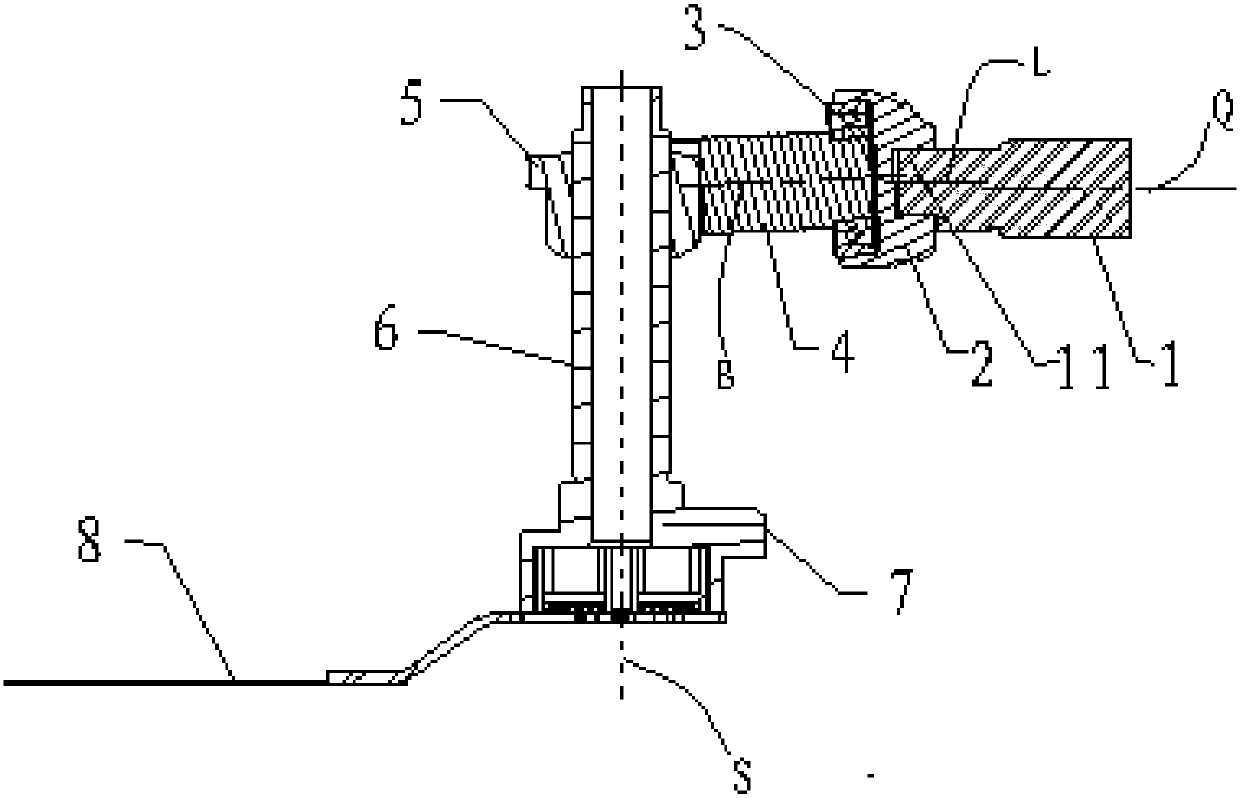

[0040] The output shaft 6 is set at an angle with the drive shaft 1, and is used for installing working accessories;

[0041] The swing transmission mechanism is connected between the drive shaft 1 and the output shaft 6, and has a transmission member and a toggle assembly; the transmission member is connected to the drive shaft 1; the first end of the toggle assembly connected to the transmission member, the second end is rotatably connected to the output shaft around the pivot axis G, wherein the pivot axis G is perpendicular to the axis of the output shaft 6 (ie the output shaft axis S), And pass through the intersection of the drive shaft 1 and the output shaft axis S; the axis extending from the first end to the second end of the toggle assembly is the toggle axis B, and the toggle Axis B forms an inclination angle w...

Embodiment 2

[0052] The difference between Embodiment 2 and Embodiment 1 lies in the structure of the toggle piece and the connection method between the toggle piece and the bearing, specifically: the toggle piece is a shift fork, and the main body is a shift fork sleeve; The transmission member is an eccentric member, and the eccentric member includes an eccentric part 2 connected with the drive shaft 1 and a bearing 3 arranged outside the eccentric part 2, and one end of the drive shaft 1 is connected to the bearing 3 The axis of the fork is coaxially inserted into the bearing 3, and the shift fork sleeve is sleeved outside the bearing 3.

Embodiment 3

[0054] The difference between Embodiment 2 and Embodiment 1 lies in the structure of the follower and the position of the follower on the output shaft, specifically: the follower has a through cavity, and the side of the through cavity There is a through hole on the wall, the upper end of the output shaft is inserted into the through hole, and the space in the through cavity is suitable for connecting the functional part to the upper end of the output shaft.

[0055] Such as Figure 4 As shown, a multifunctional machine of the present invention includes a casing, a power structure arranged in the casing, and a swing mechanism driven by the power structure is connected to the output shaft 6 of the swing mechanism, and the swing mechanism is driven by the swing mechanism. The working attachment 8 is driven by a swing mechanism, and the swing mechanism is the above-mentioned swing mechanism. Usually the power structure is a motor. Because the multifunctional machine of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com