Organic fiber dispersing and adding device

An organic fiber and dispersion technology, applied in the direction of selling raw material supply devices, etc., can solve the problem of unstable fiber dispersion effect, achieve the effect of improving dispersion stability, reducing construction cost, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

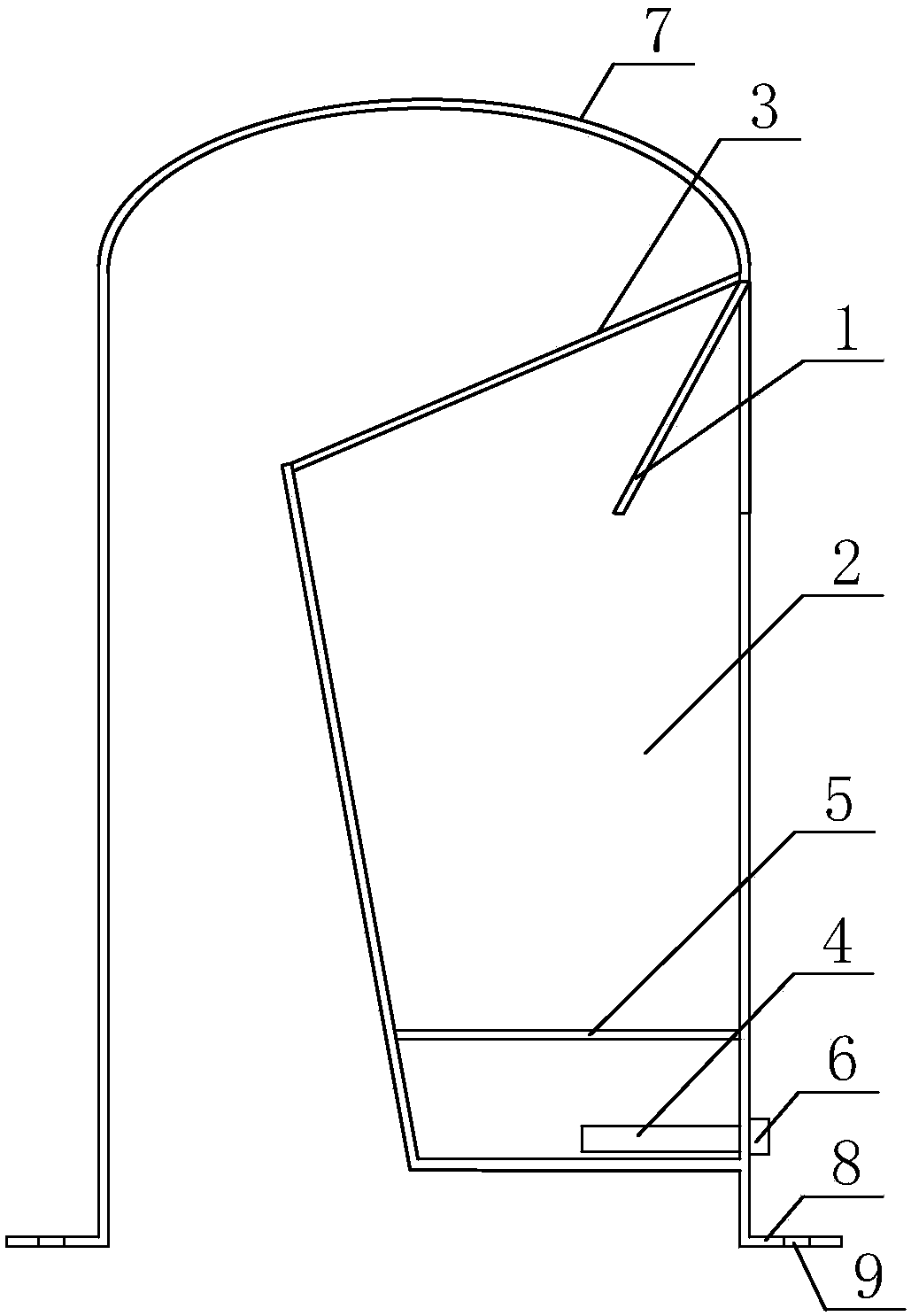

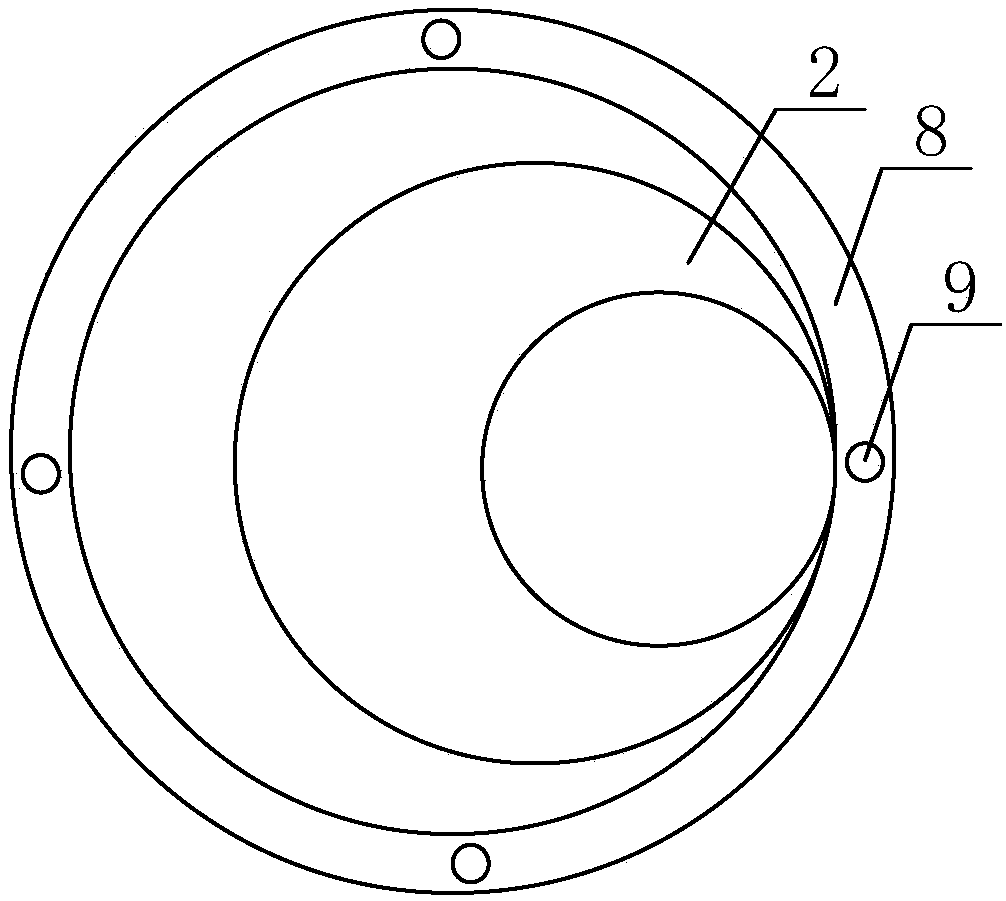

[0026] An organic fiber dispersing and adding device, such as figure 1 and figure 2 As shown, it includes a decomposition container 2 with a feeding door 1 , a wind power generating device that provides wind power from bottom to top for the decomposition container 2 , and a top filter screen 3 arranged at the top of the decomposition container 2 .

[0027] In the present invention, the arrangement of the wind generating device is various, such as a blower fan directly connected to the bottom of the decomposition container 2 at the air outlet, and directly provides wind power for the decomposition container 2 through the blower fan. As the optimal way of setting, in this embodiment, the wind power generating device has two air outlets, and one of the air outlets communicates with the bottom of the decomposition container 2, and the other air outlet is arranged on the air supply pipe 4 above the top filter screen 3 , the bottom filter screen 5 that is arranged at the bottom of...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the position setting of the feeding door 1 on the decomposition container 2 is limited. In the present invention, the feeding door 1 can be arranged on the top of the decomposition container 2 or on the side wall of the decomposition container 2 .

[0033] In order to facilitate feeding, and in the feeding process, the decomposition of fibers can still be effectively carried out in the decomposition container, the present embodiment is preferably provided with a feeding door 1 on the side wall of the decomposition container 2, such as figure 1 shown.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that an outer cover 7 and a base 8 are added in this embodiment, and the specific settings of this embodiment are as follows:

[0036] The decomposition container 2 is also provided with an outer cover 7 with an open bottom. The outer cover 7 is used to block the fiber blown from the top filter screen 3 position, and guide the fiber into the stirring tank from the bottom opening position.

[0037] In order to facilitate the installation of the present invention on the mixing tank, a base 8 is provided at the bottom of the outer cover 7 in this embodiment, and a bolt hole 9 is provided on the base 8 . When in use, it is only necessary to fix the base 8 to the observation window cover of the mixing tank by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com