Novel woodworking engraving machine

An engraving machine and woodworking technology, applied in the field of wood, can solve the problems of operator's health threat, non-compliance with production needs, affecting production efficiency, etc., and achieve the effect of reducing physical harm, increasing functionality, and functional integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

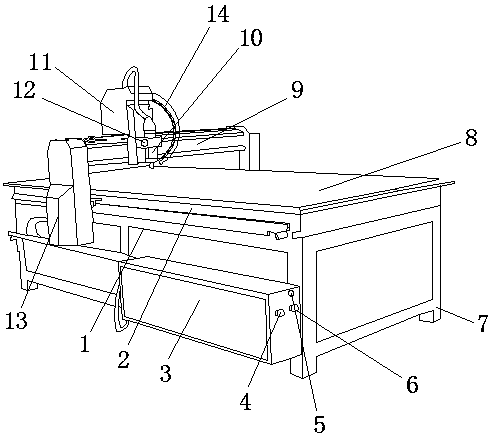

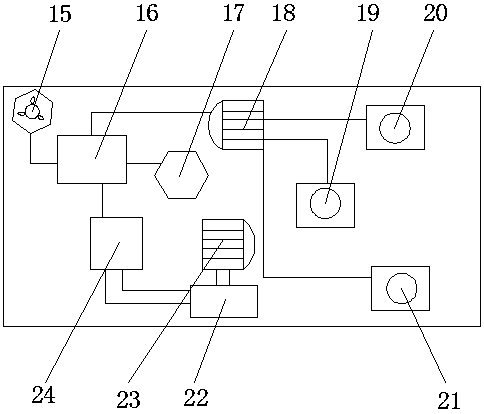

[0015] refer to Figure 1-2 , a new type of woodworking engraving machine, including engraving machine main body 1, control box 3, crossbeam 9, engraving machine head 10, moving shaft 11, powerful vacuum tube 14, controller 16 and engraving device 17, engraving machine main body 1 top installation There is a moving track 2, and a control box 3 is installed under the moving track 2, a stop button 4 is arranged on the surface of the control box 3, and an engraving machine working button 6 is installed on the right side of the stop button 4, and a moving block 13 is installed on the left side of the control box 3 , and a crossbeam 9 is installed on the right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com