Sewing device

A sewing and sewing machine technology, applied in the field of sewing devices with post-tension mechanism, can solve the problems of rising labor costs, high labor intensity, unevenness, etc., and achieve the effect of reducing sewing costs and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

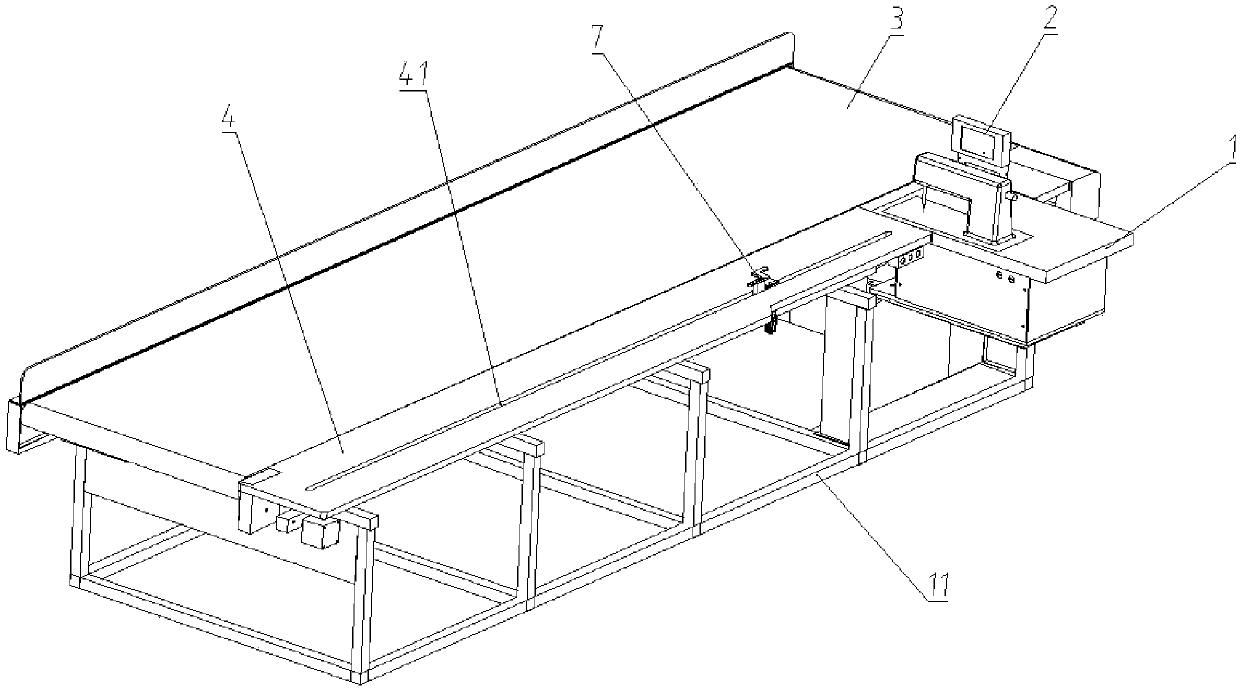

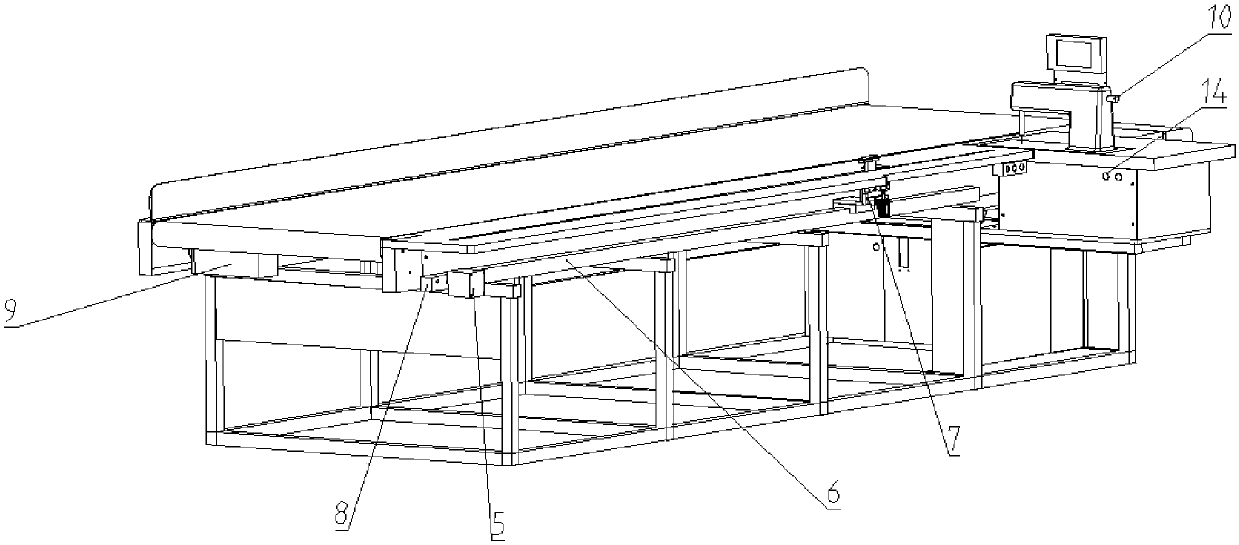

[0018] Such as Figure 1-4 Said sewing device includes a frame 11, a sewing machine 1 supported on the frame 11, and a tension mechanism on the feeding side of the sewing machine 1. The tension mechanism is used to align the stitching edges of the two cloths to be stitched and has a certain pre-tightening force (tension), and the pre-tightening force keeps the two stitching edges aligned before sewing.

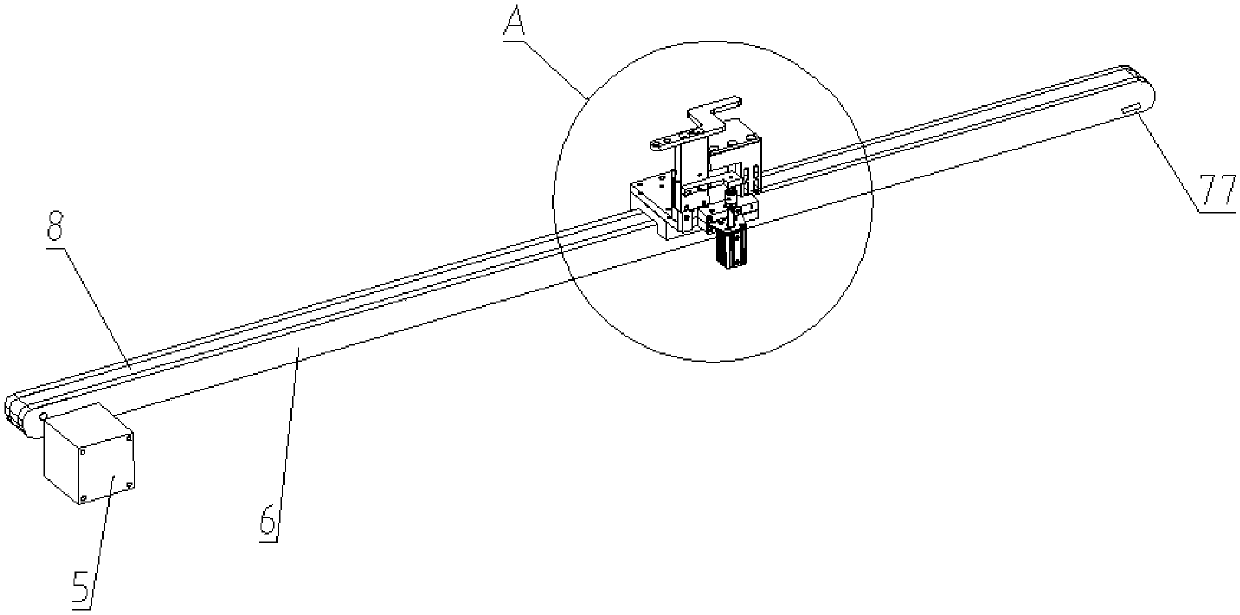

[0019] Specifically, the tension mechanism includes a guide rail 6 supported on the frame 11 along the feeding direction, a slider 61 matched with the guide rail 6, and a clamping mechanism 7 fixed on the slider 61. The slider 61 can Relative to the guide rail 6 sliding along the feeding directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com