Full prefabricated pre-stress assembly type structure and construction method thereof

A construction method and prestressing technology, applied in the direction of building structure and construction, can solve the problems of backward construction technology, low construction efficiency, increased construction cost, etc., and achieve good overall assembly and stability, guaranteed seismic performance, The effect of small section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Assembled prestressed structure of cast-in-place slab.

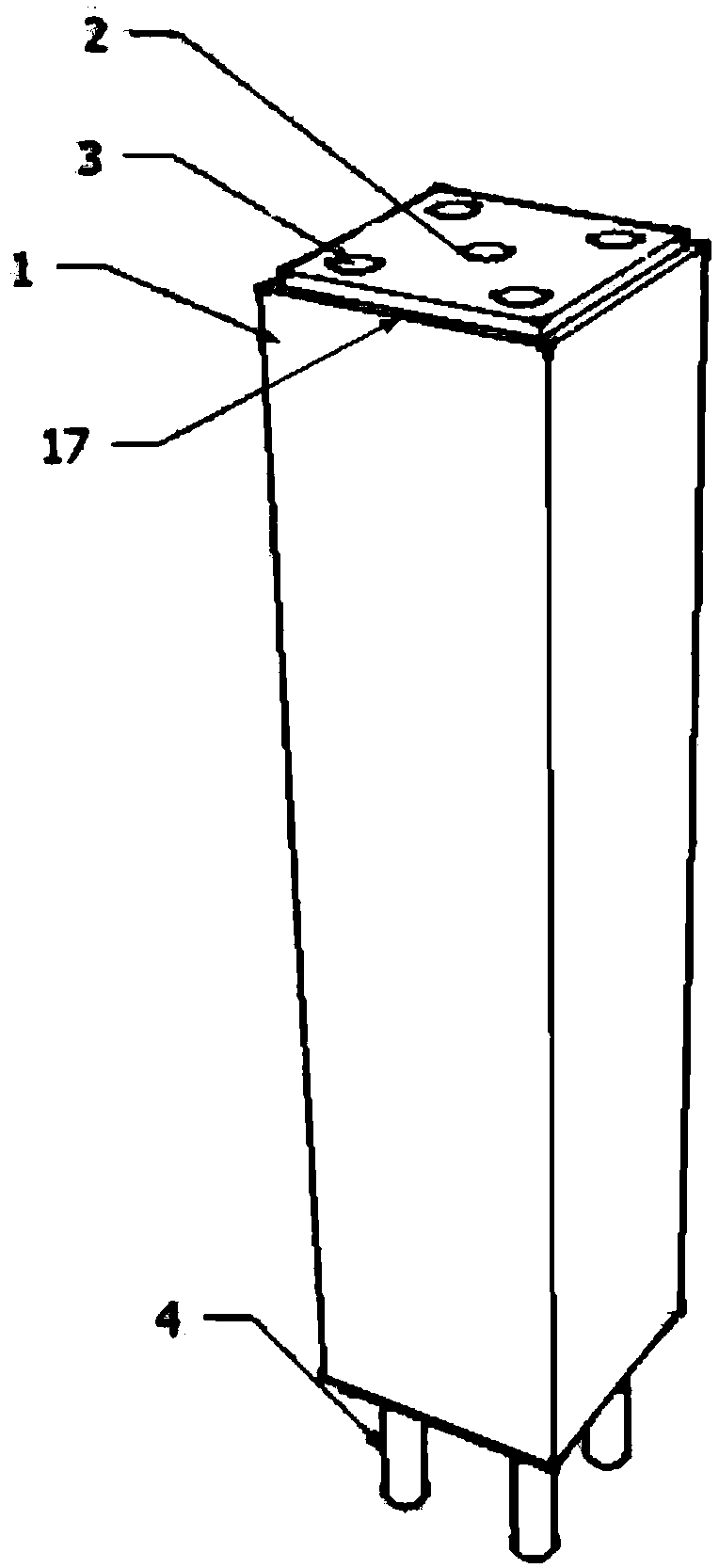

[0034] After the foundation is poured according to the design requirements, the steel strands are fixed to the embedded parts of the foundation at the centerline of each column foundation to provide a fixed end for the subsequent prestressing of the columns. Afterwards, start to hoist the bottom node columns. When hoisting the beam members of the adjacent spans, the following two construction techniques are adopted: spreading from the corners to the center, or spreading from the center to the sides.

[0035] Arrange the corners toward the center: After the assembly of the corner column 1a is completed, transport the horizontally and vertically adjacent beam members a and b to the storey height, erect one end on the pre-embedded angle steel 6 on the column, and fix the other end with equipment first. Then set up two node columns 2a, 3a adjacent to the longitudinal axis and the horizontal axis. Before ...

Embodiment 2

[0041] Embodiment 2: Prefabricated floor slab (with doors, windows and walls) prefabricated prestressed structure.

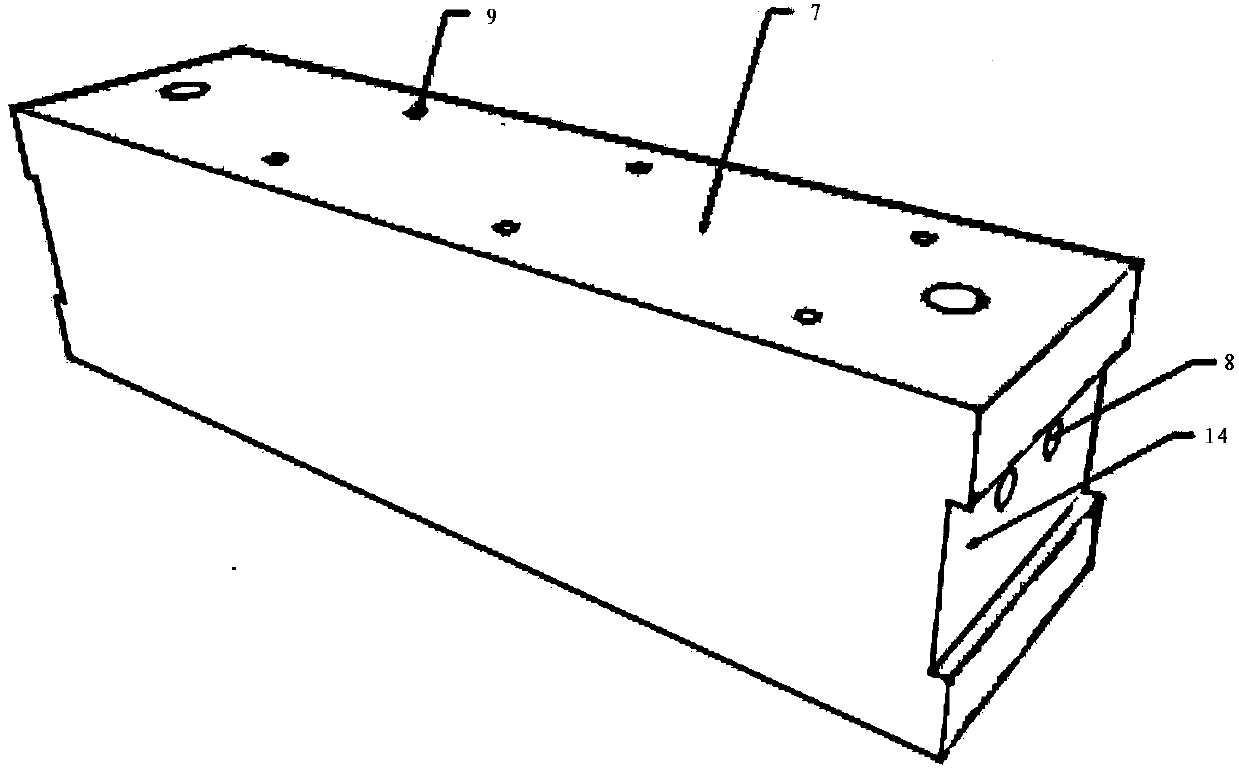

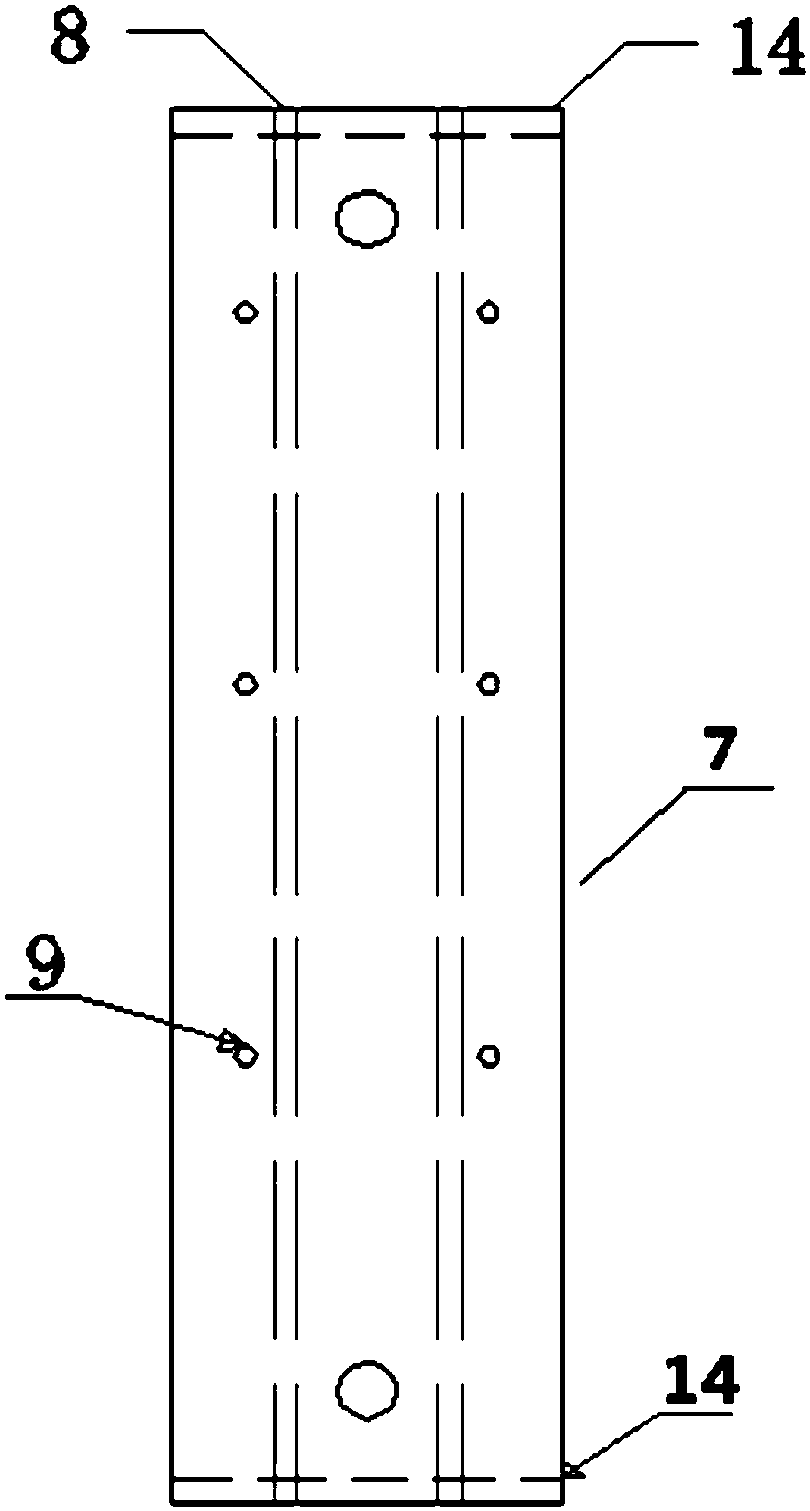

[0042] The preliminary process is the same as that of Example 1 until the assembly of the beam-column system is completed. The assembly method of the beam-column system can also adopt the above-mentioned two construction techniques of edge-to-center and center-to-edge, and then assemble the prefabricated slab and the beam, and adopt the following method: insert the elbow reinforcement of the prefabricated slab The plate is connected with the hole 9, and the basic fixing of the elbow steel bar can be completed at the bottom of the two to complete the combination of the beam and the plate. Next, if there is a prefabricated body of wall, the body of wall is embedded on the plate along the column side chute from top to bottom, and the reinforcing bar convex key 12 on the plate is fixed to the bottom of the body of wall from top to bottom. Complete the overall assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com