Feature-processing-based complex equipment fault diagnosis method

A technology of equipment failure and diagnosis method, which is applied in the direction of instruments, character and pattern recognition, computer components, etc., and can solve the problems of diagnostic model adaptability and fault-tolerant design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following detailed description will be given in conjunction with the accompanying drawings.

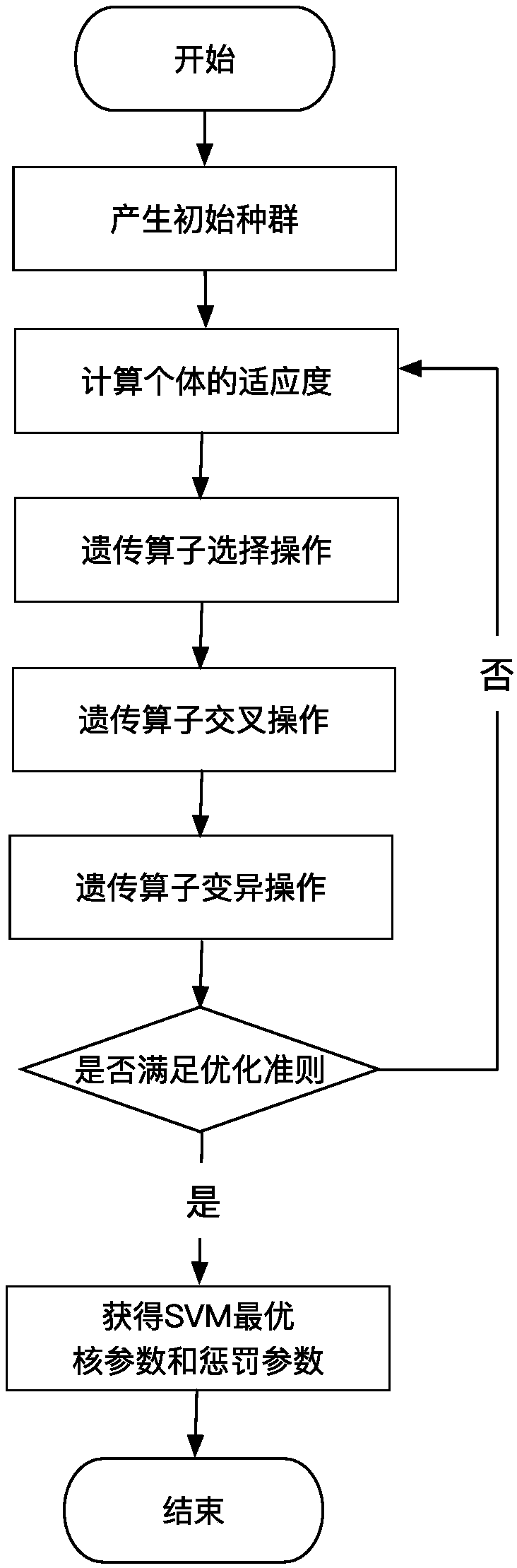

[0079] The present invention proposes a fault diagnosis method for complex equipment based on feature processing and support vector machine. The method can be used to characterize the action signal data of the complex equipment to obtain a feature representation data set. Based on the feature representation data set, combined with the GA-PSO algorithm and the SVM model, a fault diagnosis model is obtained through the supervised learning mechanism, which is used for equipment fault judgment and identification.

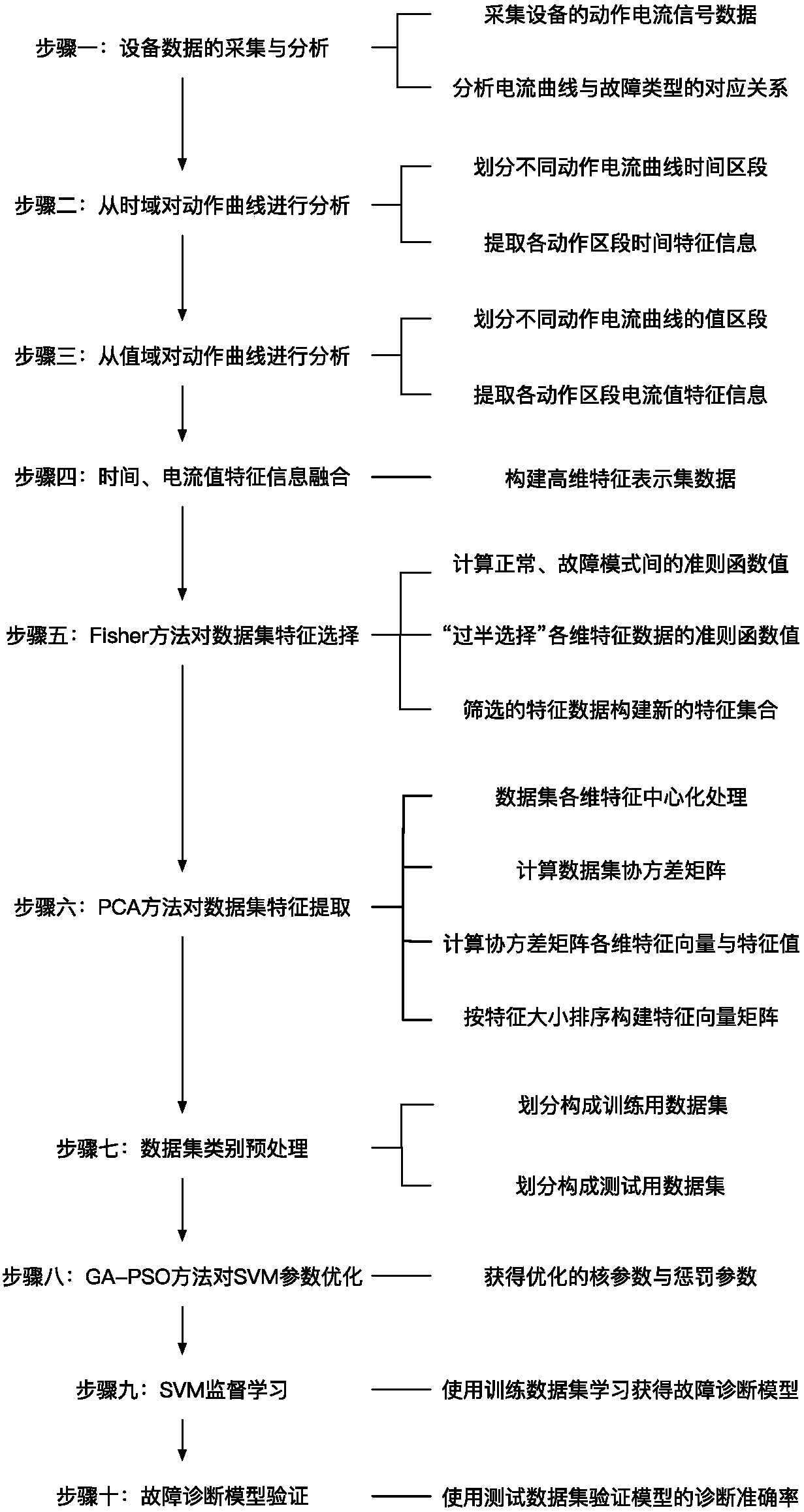

[0080] The present invention is a complex equipment fault diagnosis method based on feature processing and support vector machine, such as figure 1 The specific implementation steps are as follows:

[0081] Step 1: Collect the operating current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com