Formula generation method and system of printing and dyeing work orders

A generation system and formula technology, applied in the field of printing and dyeing technology, can solve the problems of low judgment efficiency and inaccurate judgment, and achieve the effect of improving generation efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

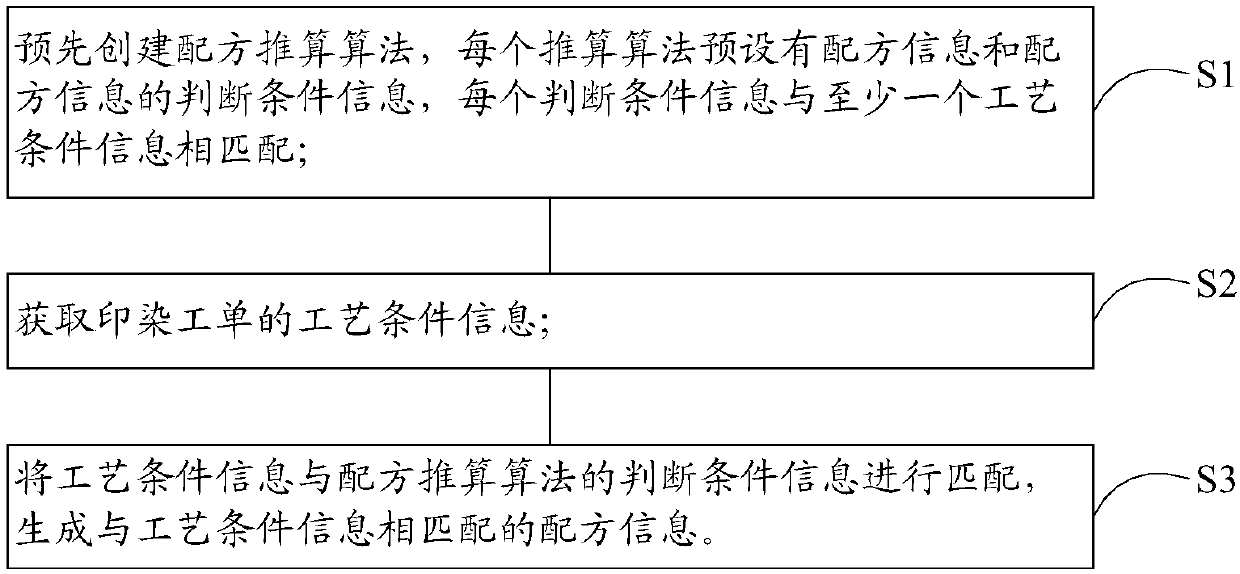

[0044] Such as figure 1 As shown, a method for generating a recipe of a printing and dyeing work order of the present invention includes the following steps:

[0045] S1. Create a formula calculation algorithm in advance, each calculation algorithm is preset with formula information and judgment condition information of the formula information, and each judgment condition information matches at least one process condition information;

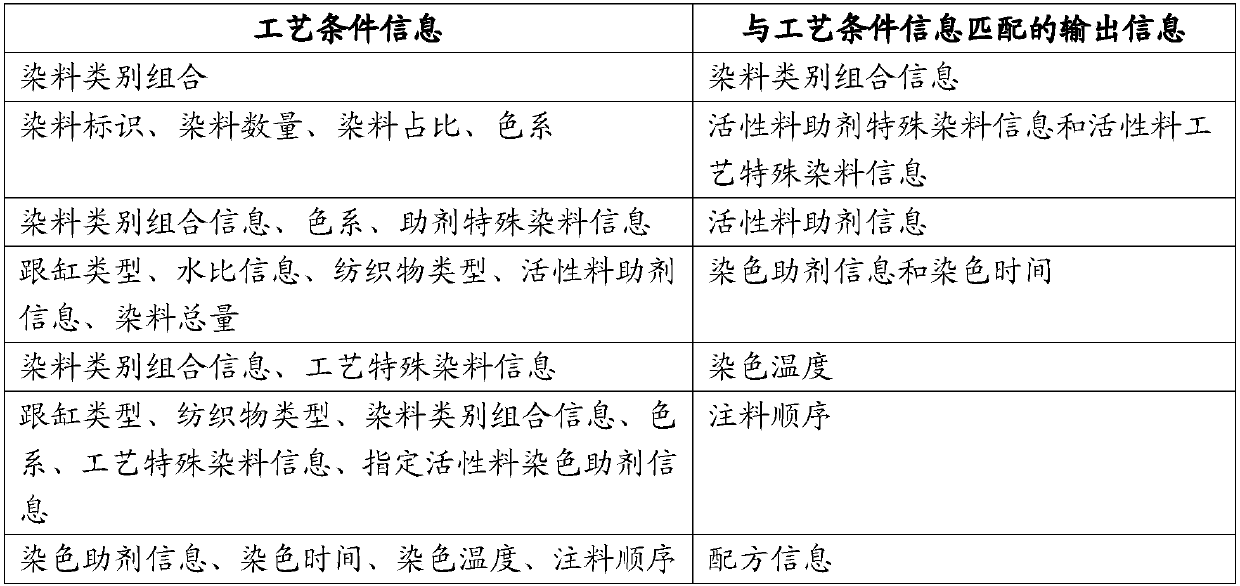

[0046] Step S1 of the present invention includes a plurality of calculation algorithms, and each calculation algorithm generates corresponding formula information according to the judgment condition information of the formula information. For example, including the calculation of the dyeing formula of the first active material, the calculation of the dyeing formula of the second active material, the calculation of the post-treatment formula of the first active material, the calculation of the post-treatment formula of the second active material...

Embodiment 2

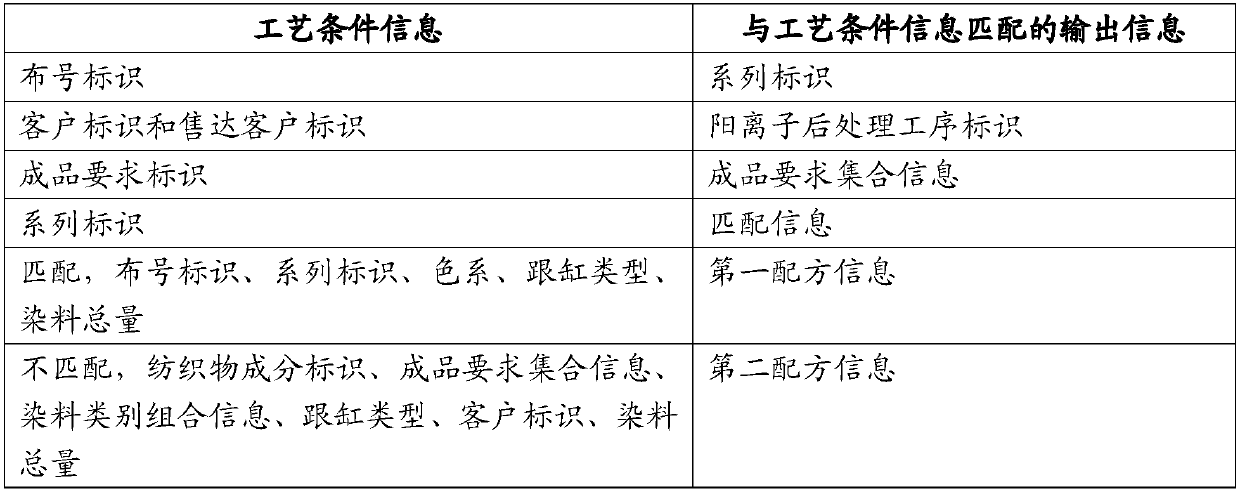

[0076] Such as Figure 5 As shown, it is a formula generation system for printing and dyeing work orders of the present invention, including: a calculation algorithm creation module 1, which is used to create a formula calculation algorithm in advance, and each calculation algorithm is preset with formula information and judgment condition information of the formula information, Each judging condition information is matched with at least one process condition information; the information acquisition module 2 is used to obtain the process condition information of the printing and dyeing work order; the formula information generation module 3 is used to combine the process condition information with the judgment condition information of the formula calculation algorithm Matching is performed to generate recipe information that matches the process condition information.

[0077] Compared with the prior art, in the formula generation system of a printing and dyeing work order of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com