Cathode plate of a bipolar element and method for operating such a cathode plate

A cathode plate and pole element technology, which is applied to electrical components, fuel cell parts, fuel cells, etc., can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

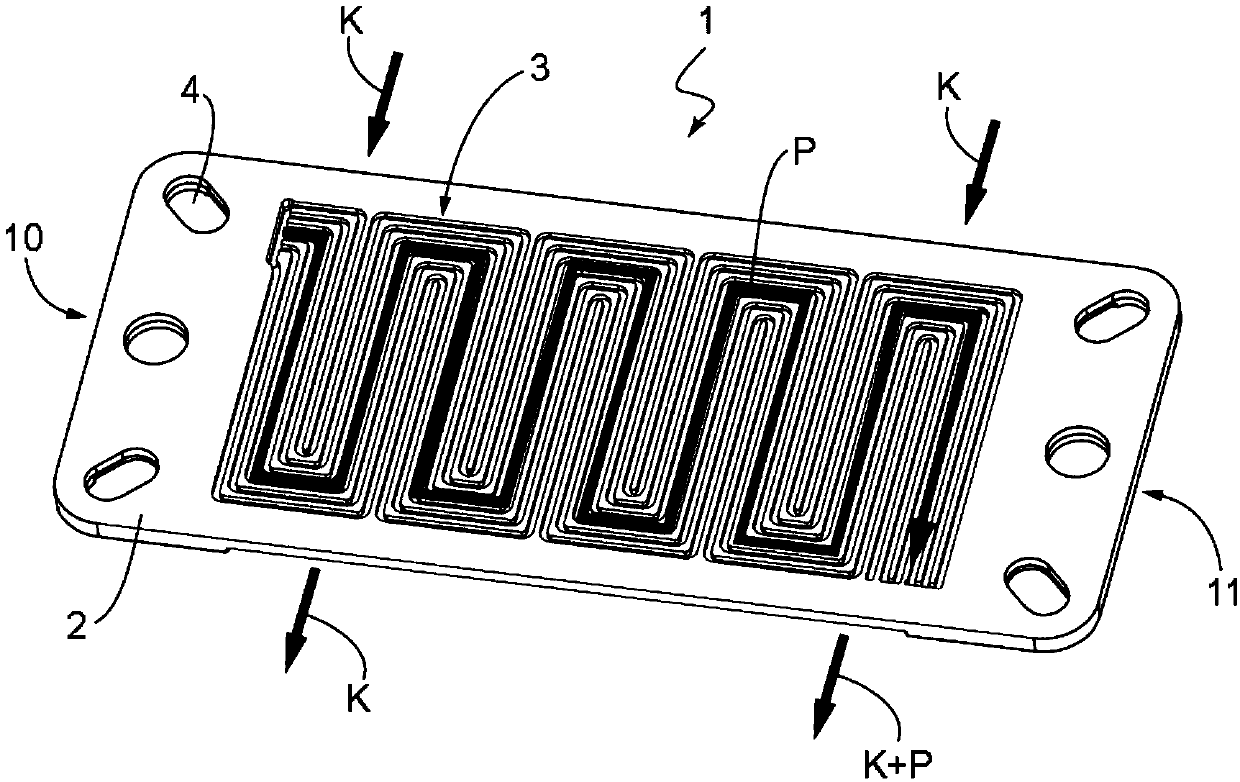

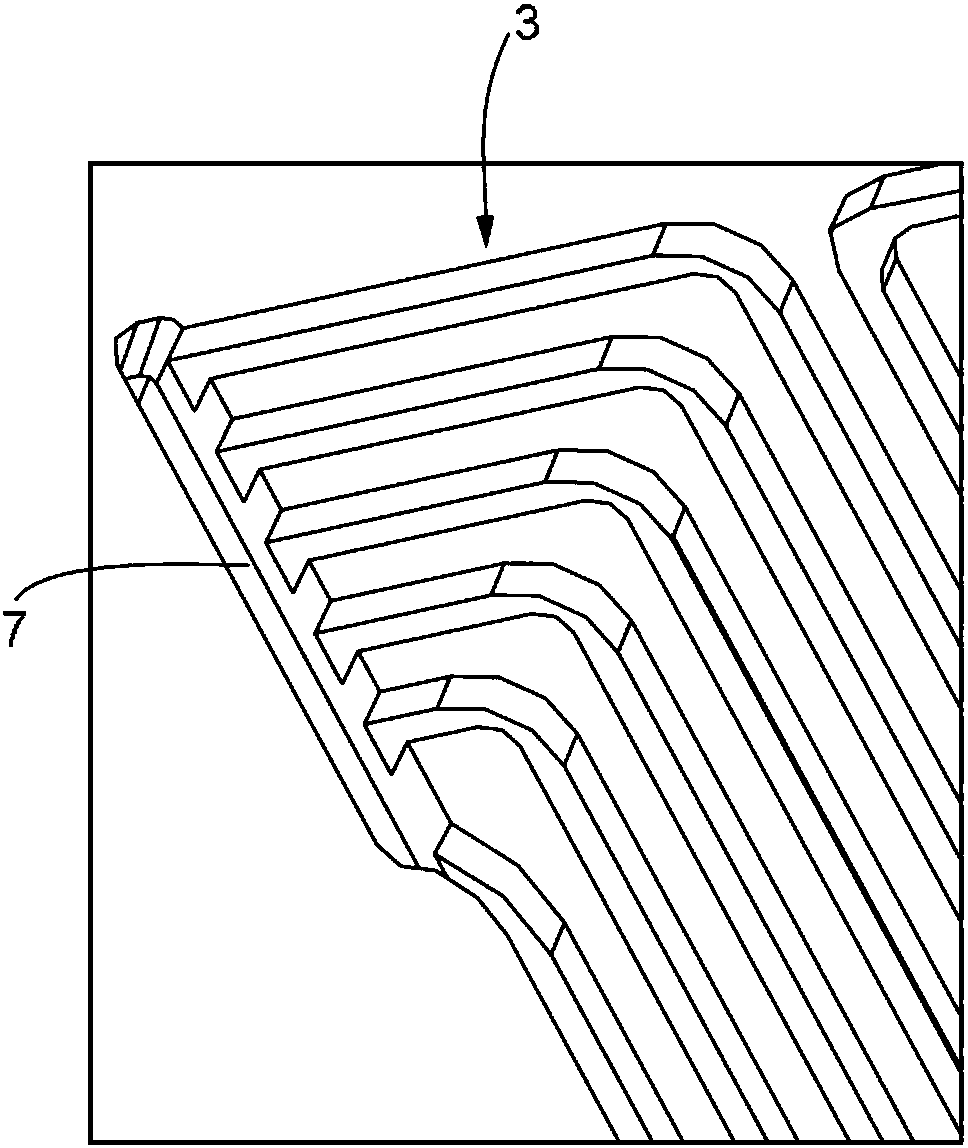

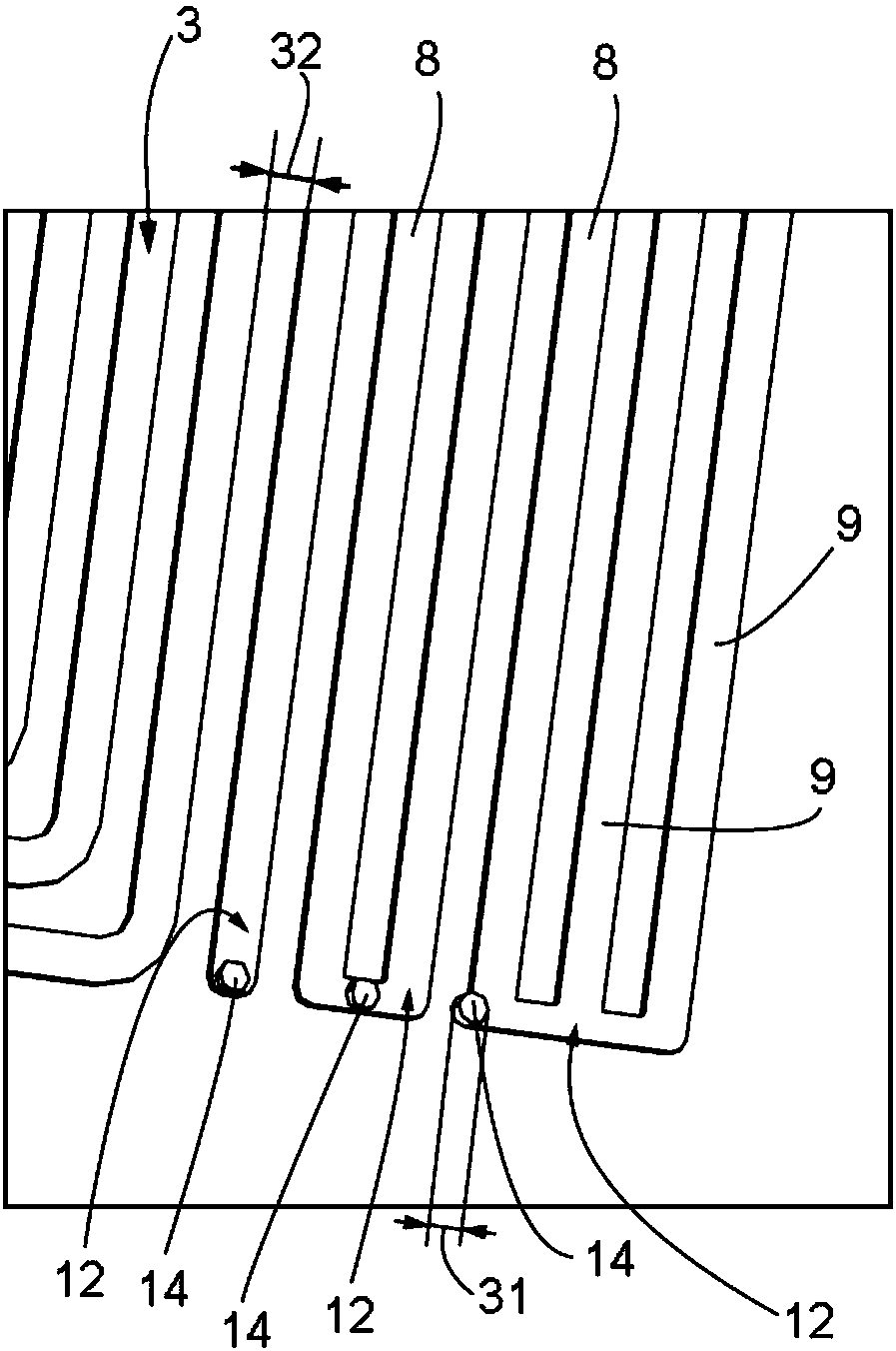

[0034] Figure 1 to Figure 6 Different views of the cathode plate 1 according to the invention according to the first embodiment are shown, correspondingly in Figure 7 and Figure 8 A second embodiment of a cathode plate 1' according to the invention is shown in .

[0035] As is known from the prior art and explained above, the cathode plate 1 , 1 ′ corresponds to a partial plate which, together with the anode plate, not shown in detail in the figures, forms a fuel cell for air cooling stack of bipolar components. In this case, such a fuel cell stack has a plurality of such bipolar elements, between which corresponding membrane electrode assemblies (MEAs) are arranged and which delimit individual fuel cells.

[0036] reference in Figure 1 to Figure 6 The first embodiment of the cathode plate 1 shown in figure 1 The top view of shows the first plate side 2 of the cathode plate 1 . A cathode channel structure 3 is formed on the first plate side 2 of the cathode plate 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com