A kind of distillation equipment for chemical production

A technology for distillation equipment and chemical production, which is applied in the field of distillation equipment for chemical production, can solve the problems of long distillation time, poor heating effect and low efficiency, and achieves the effects of good effect, fast speed and larger contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

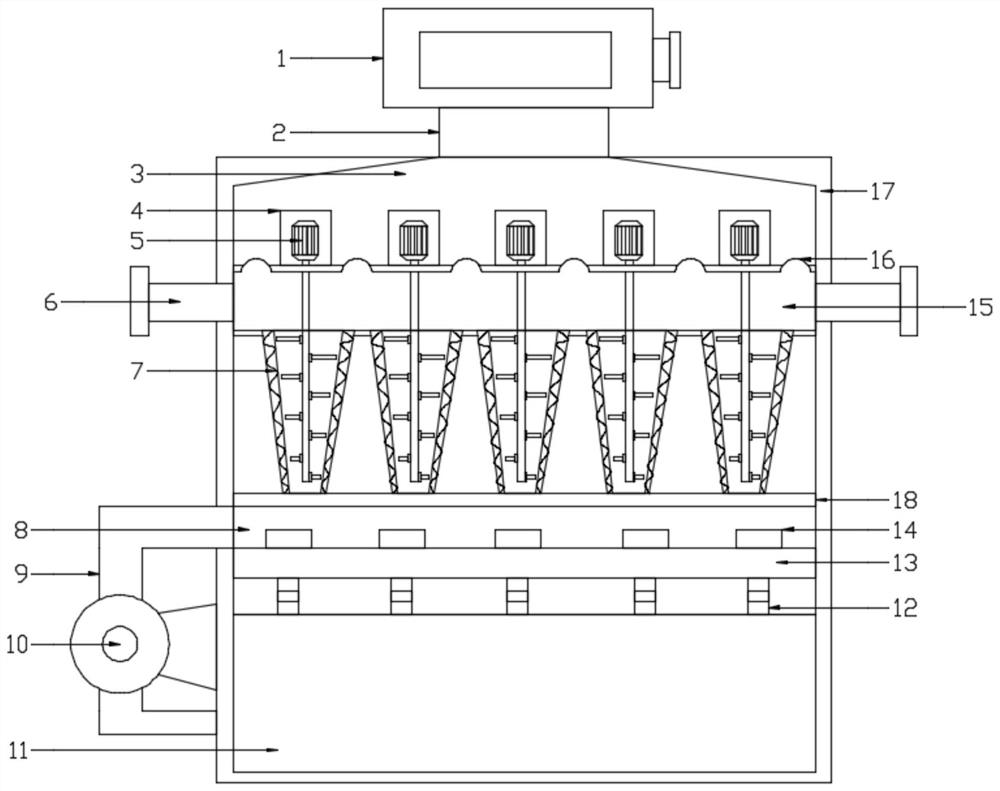

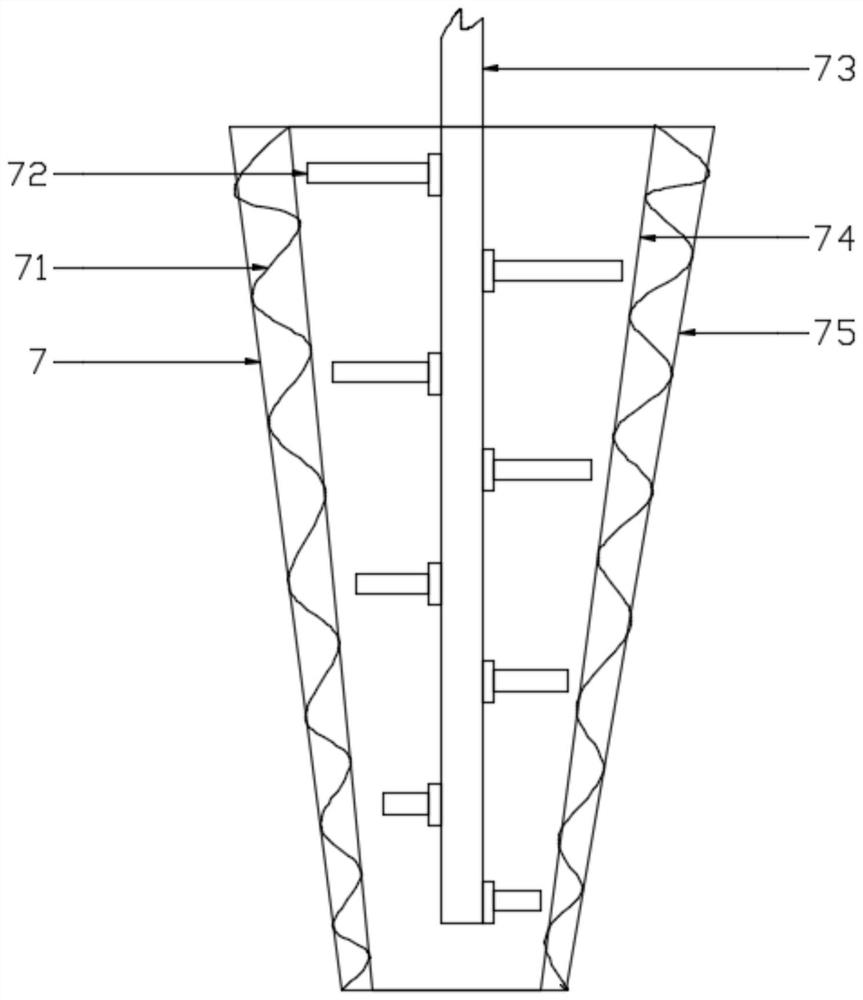

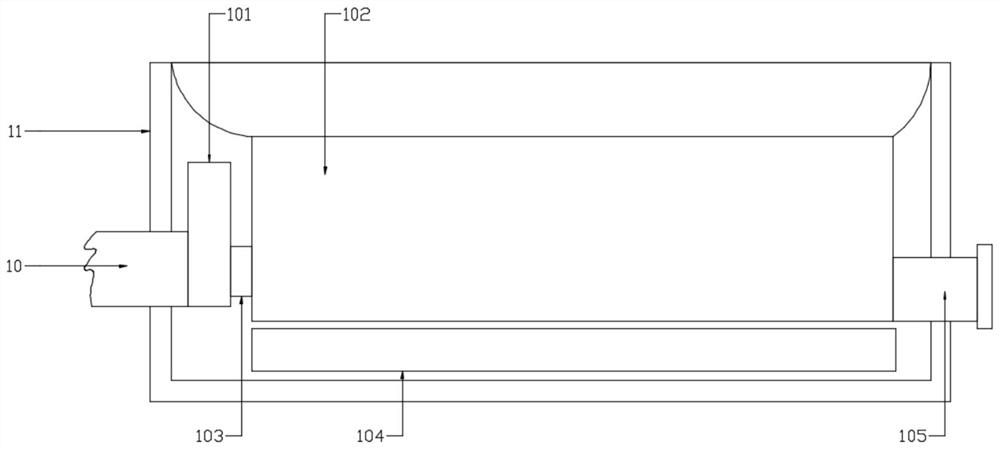

[0022] see Figure 1-4 , a kind of distillation equipment for chemical production, cavity 3, preheating pipe 7, liquid outlet layer 8, distillation box 11 and liquid inlet layer 15, the cavity 3 is arranged on the inside of the top of the equipment shell 17, the cavity The upper end of the cavity 3 is set as an arc-shaped top, and the setting of the cavity 3 is used to collect the distilled gas. The upper end of the cavity 3 is connected to the first connecting pipe 2, and the upper end of the first connecting pipe 2 is connected to the cooler 1, and the cooler 1 is provided with There is a liquid storage tank and a liquid discharge pipe. The liquid inlet chamber layer 15 is arranged at the lower end of the cavity 3, and the top of the liquid inlet chamber layer 15 is provided with an array of air outlet pipes 16, and the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com