Sweeping device of power distribution panels, boxes and cabinets of 750 kilovolt transformer substation

A technology for cleaning devices and substations, applied in switchgear, electrical components, cleaning methods and appliances, etc., can solve the problems of lowering the level of electrical insulation, difficult to guarantee the effect, and potential safety hazards, so as to reduce the number of cleanings and increase the reliability of equipment. The effect of reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

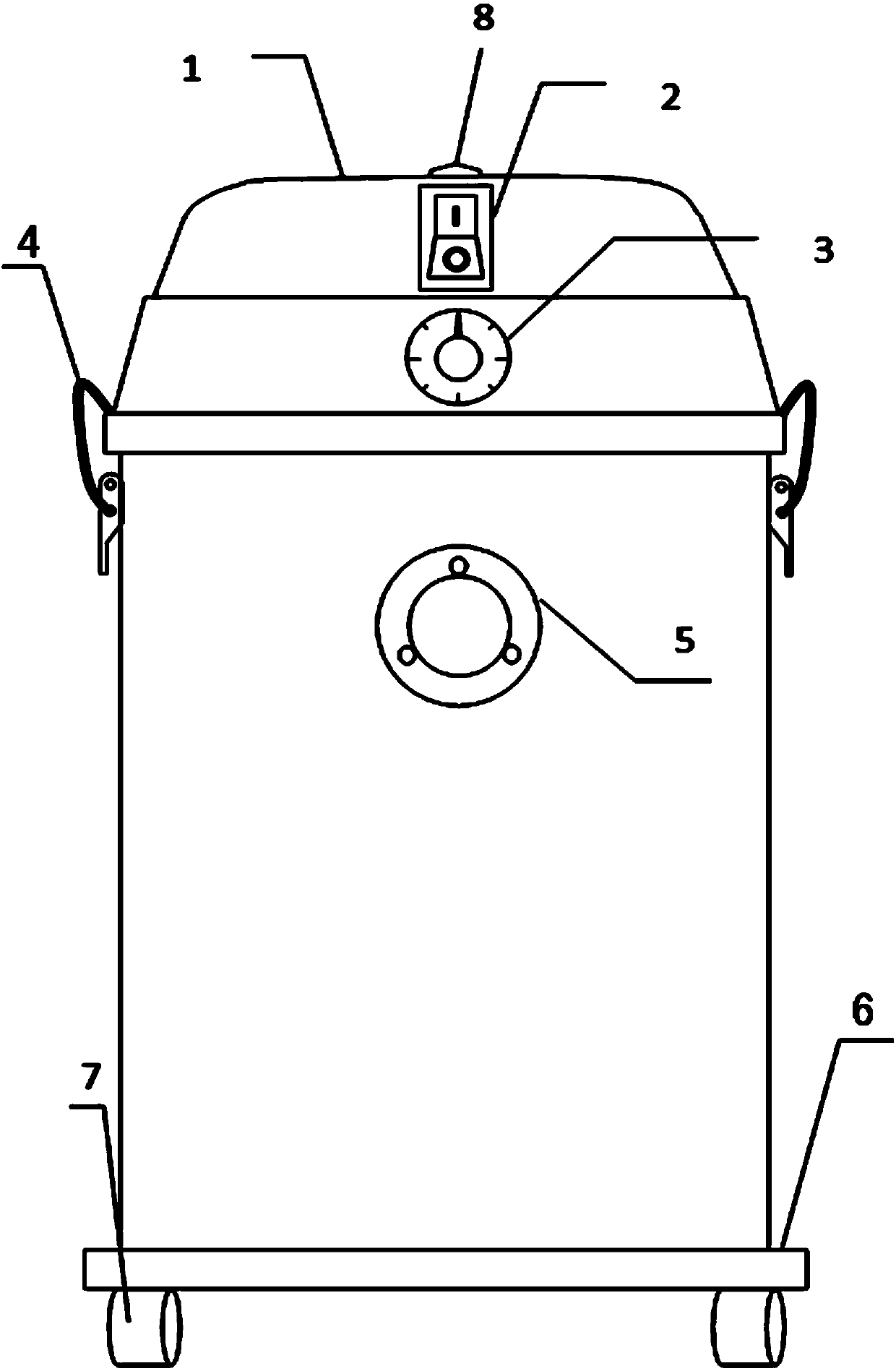

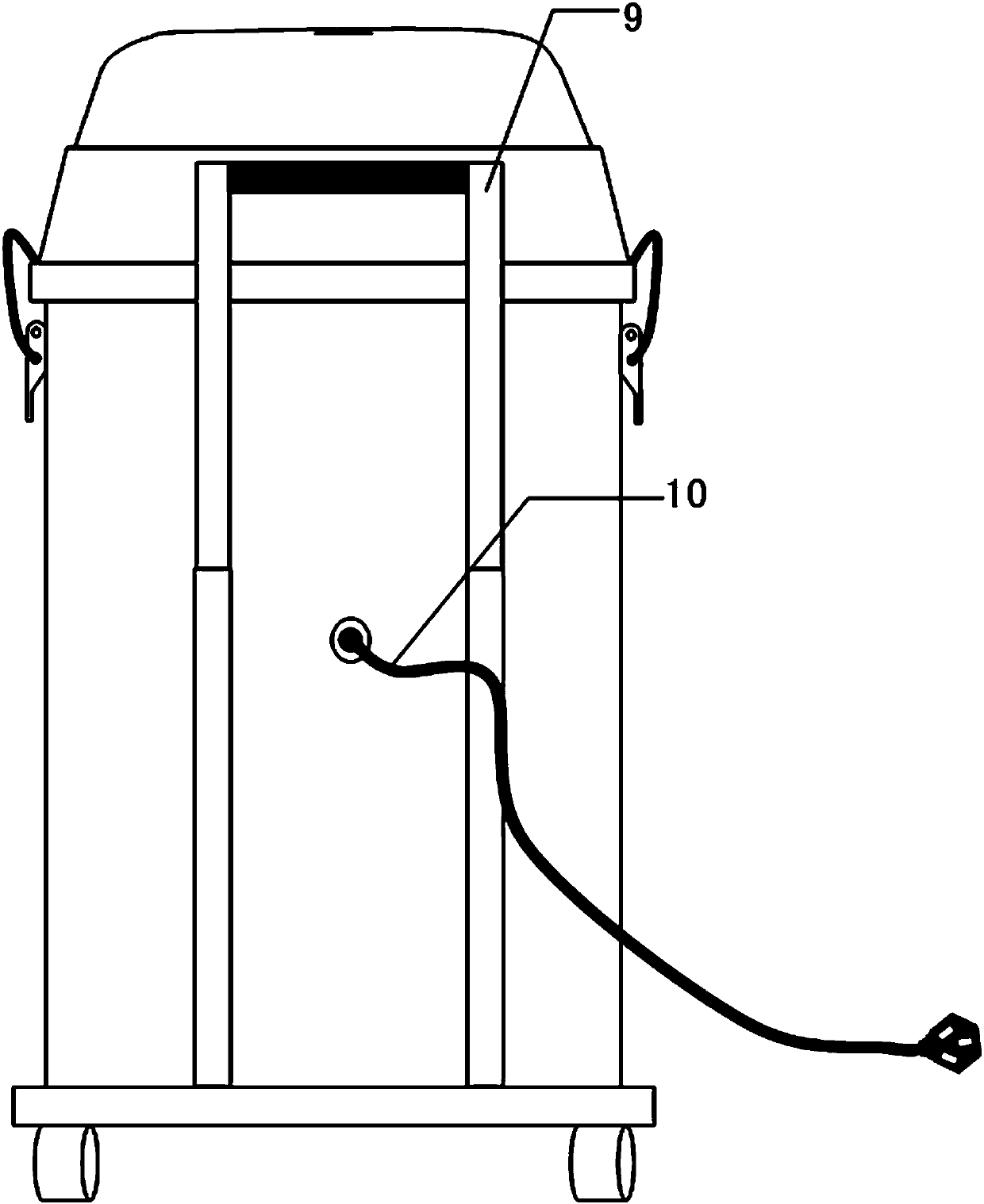

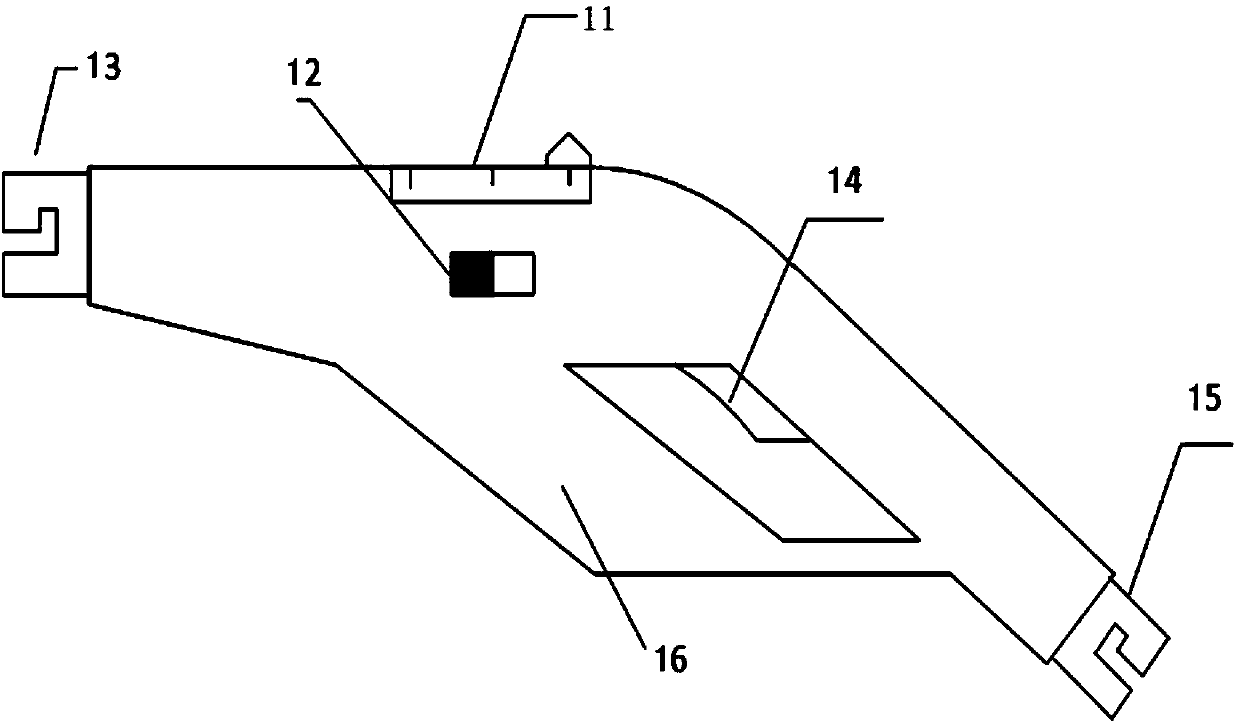

[0038] Such as Figure 1-8 As shown, it shows the specific implementation of the present invention. As shown in the figure, a 750 kV substation screen cabinet three-box cleaning device disclosed by the present invention includes a device body, which is provided with a dust suction pipe for connecting One end of the dust suction pipe interface 5, the other end of the dust suction pipe is connected to the suction pipe bayonet 15 of the cleaning control handle; in the present invention, the cleaning control handle integrates cleaning and control functions, and it is very convenient to hold the cleaning control handle Regular settings such as adjusting cleaning mode and gear position do not need to be controlled on the device body. This method is very suitable for the three-box cleaning condition of the screen cabinet in the substation and helps to improve efficiency;

[0039] The device body includes a bottom box connected by a box buckle 4 and a device top cover 1; the top outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com