Steel-aluminum laser welding technique optimizing method

A technology of laser welding and process optimization, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as increasing difficulty and lack of uniform regulations, achieving fast calculation speed, high prediction accuracy, and saving test costs and time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] The terms of direction and position mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "top", "bottom" ", "side", etc., are only referring to the direction or position of the drawings. Therefore, the terms used in direction and position are used to explain and understand the present invention, but not to limit the protection scope of the present invention.

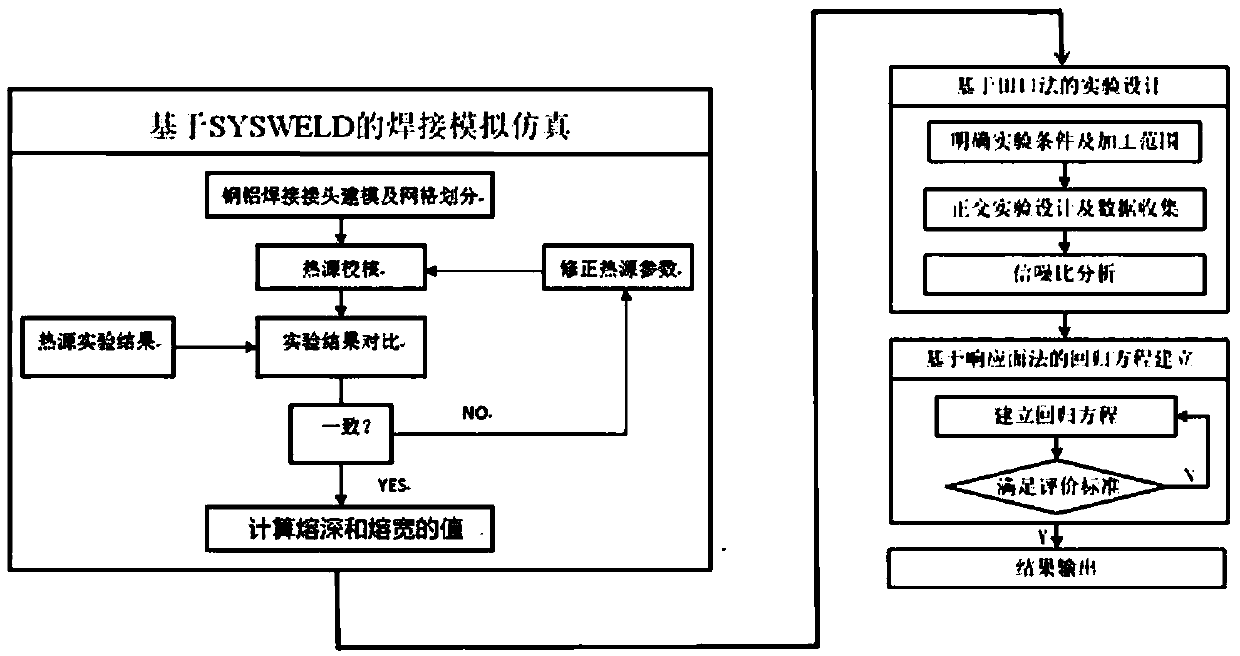

[0019] Such as figure 1 As shown, in the embodiment of the present invention, the specific implementation scheme of the method is illustrated below by taking steel / aluminum laser welding as an example:

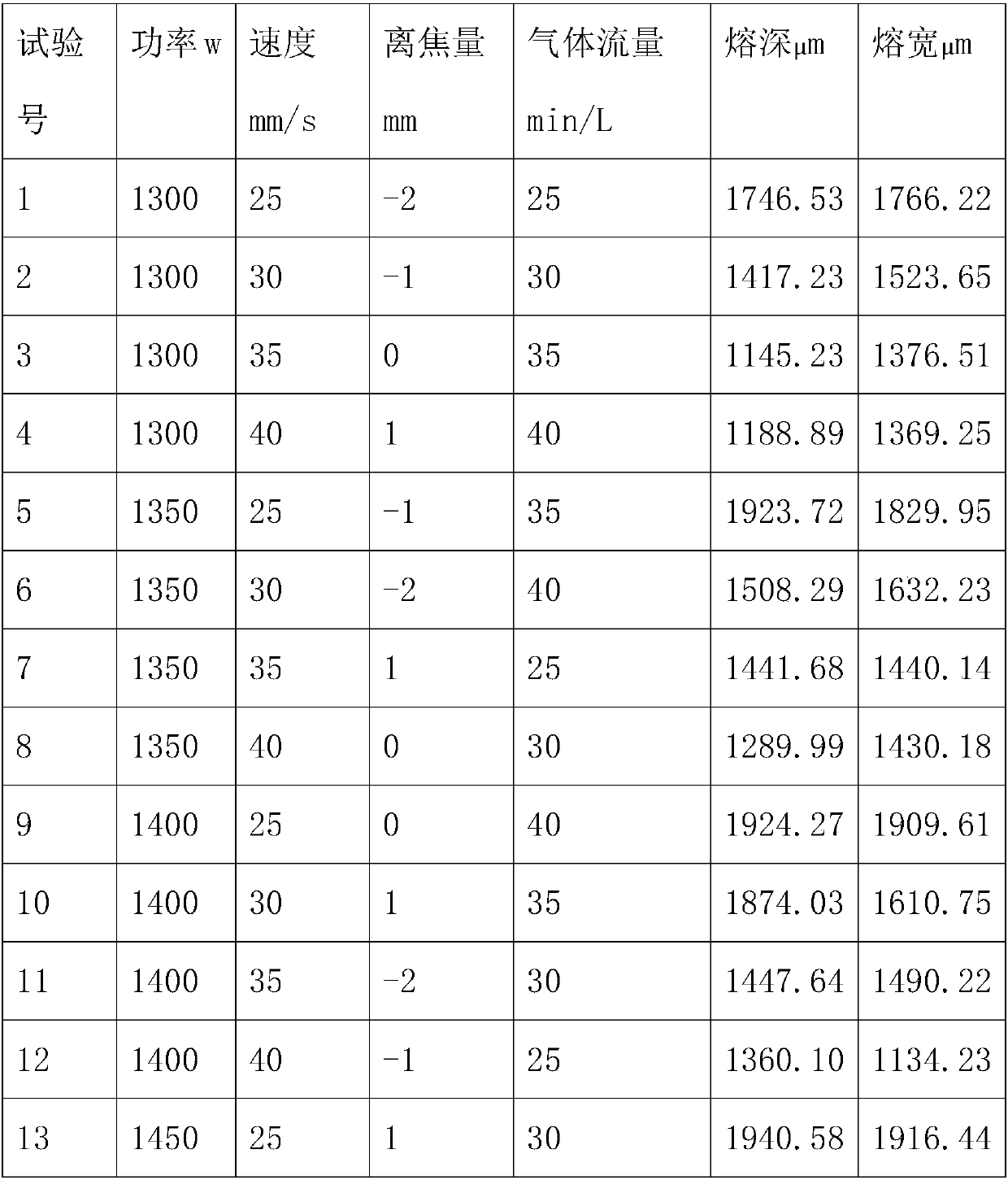

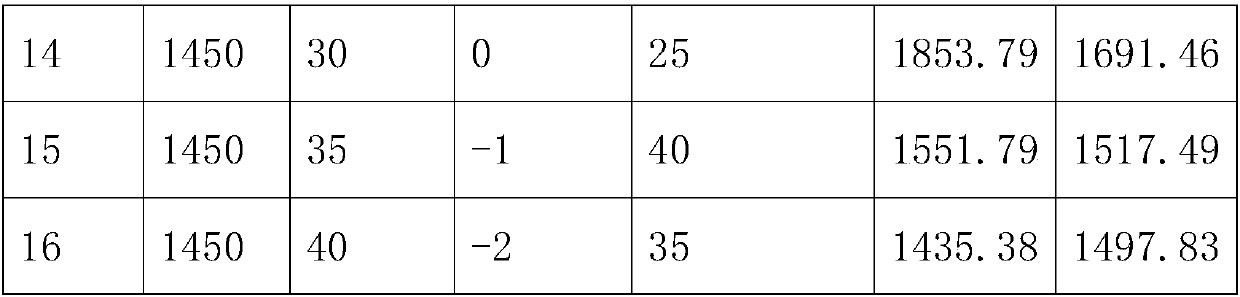

[0020] (1) Choose L 16 (4 5 ) orthogonal table to design the test program, and take the penetration depth and width of the molten pool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com