Hole punching tooling for tubular parts

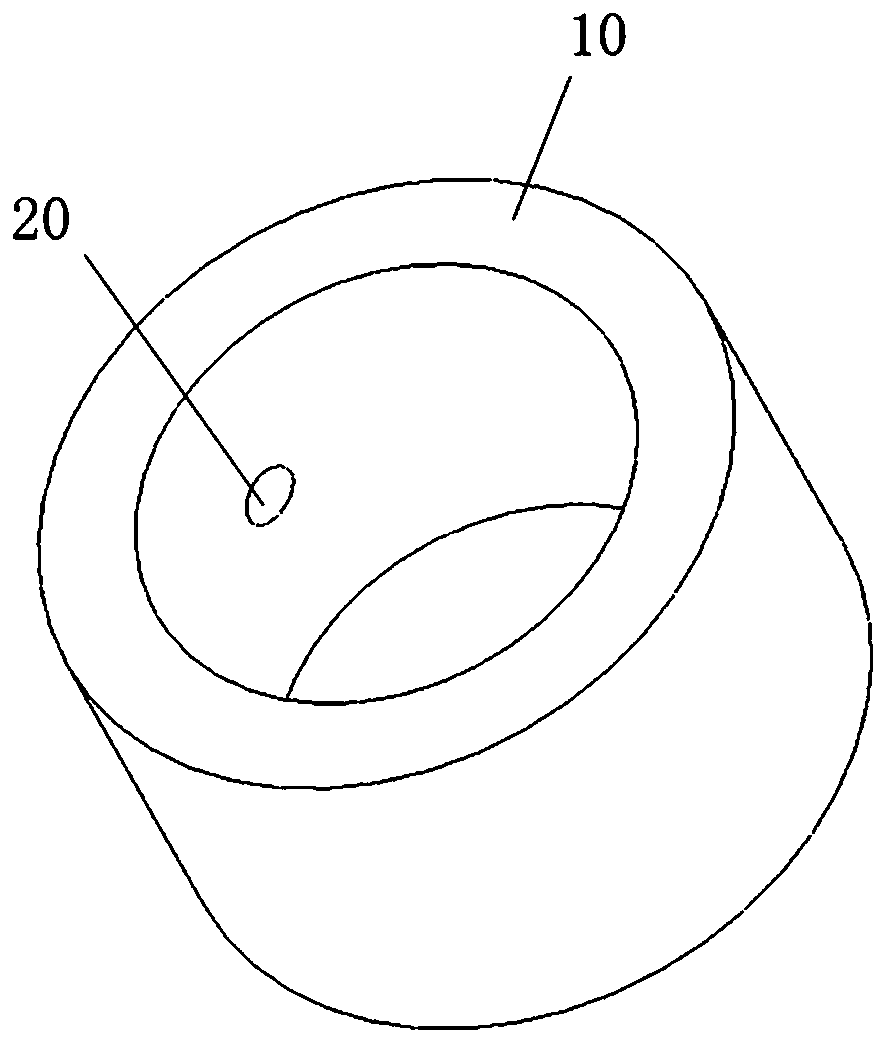

A part and tubular technology, applied in the field of drilling tooling for tubular parts, can solve the problems of affecting the accuracy of parts, out of roundness of tubular parts, affecting the accuracy of the inner diameter of parts, etc., so as to relieve stress concentration, restrain local deformation, realize The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

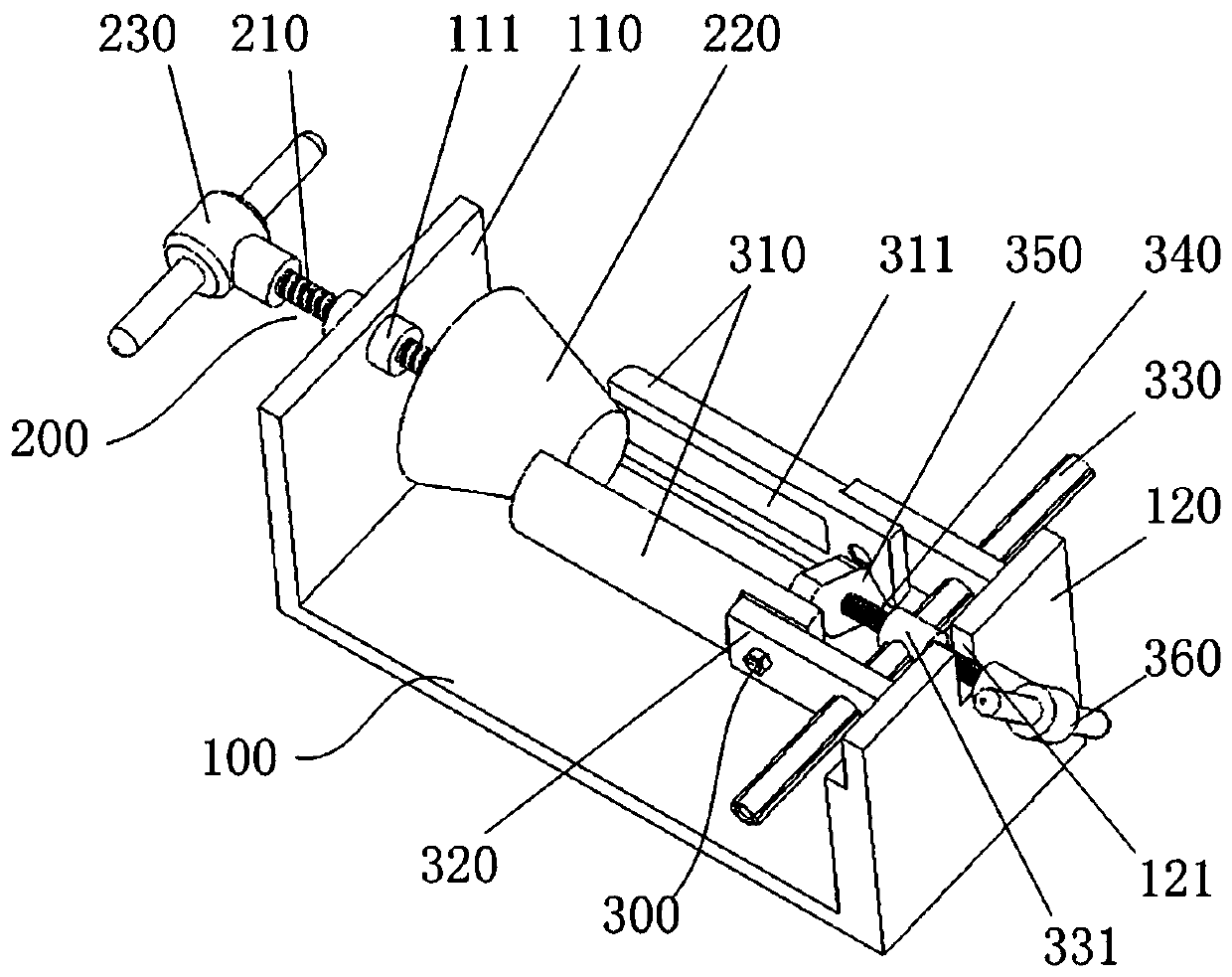

[0033] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, but not to be construed as a limitation of the present invention.

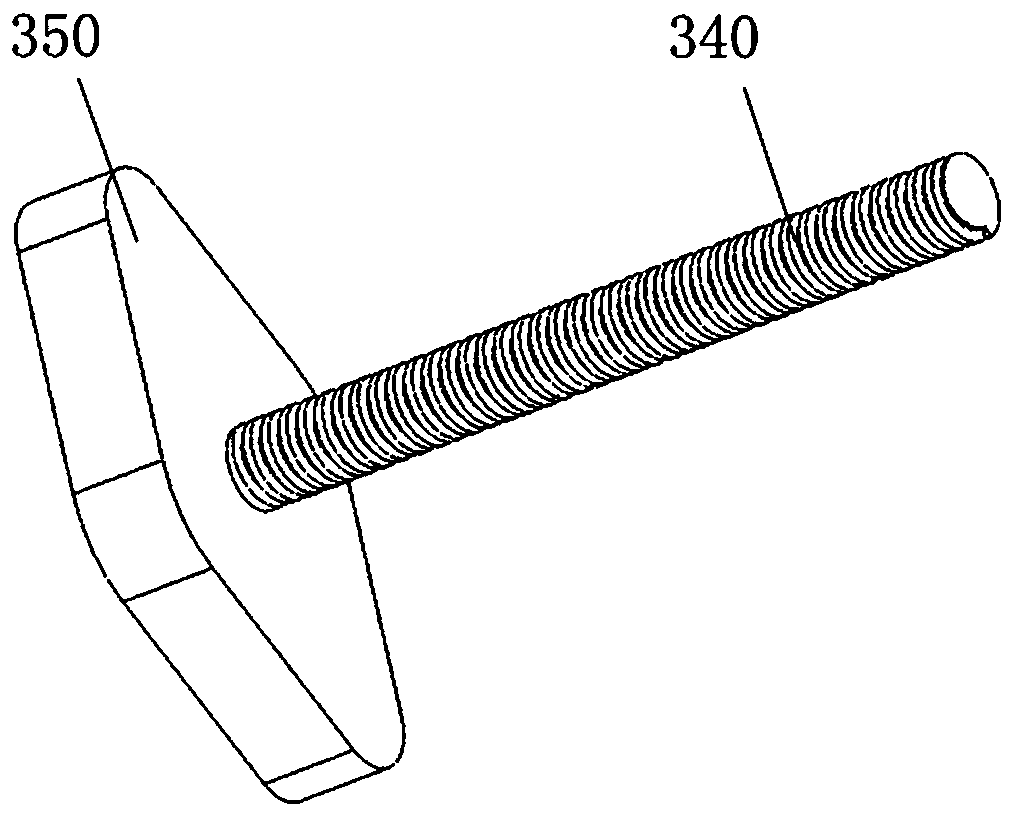

[0034] Please also refer to figure 2 and image 3 , the embodiment of the present invention provides a drilling tool for tubular parts, which includes a base 100, a pressing mechanism 200 and a supporting mechanism 300; wherein, the pressing mechanism 200 is retractably penetrated on the base 100; the supporting mechanism 300 includes The slide rail 330 , the adjustment structure and two support plates 310 , the slide rail 330 is fixedly connected to the base 100 , and the two supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com