Liftable plastic container and manufacturing method thereof

A technology for plastic containers and manufacturing methods, applied to containers, rigid containers, packaging, etc., can solve the problems of poor load-bearing capacity, insufficient load-bearing capacity, and non-replacement, etc., and achieve the effect of simple structure and process and improved load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

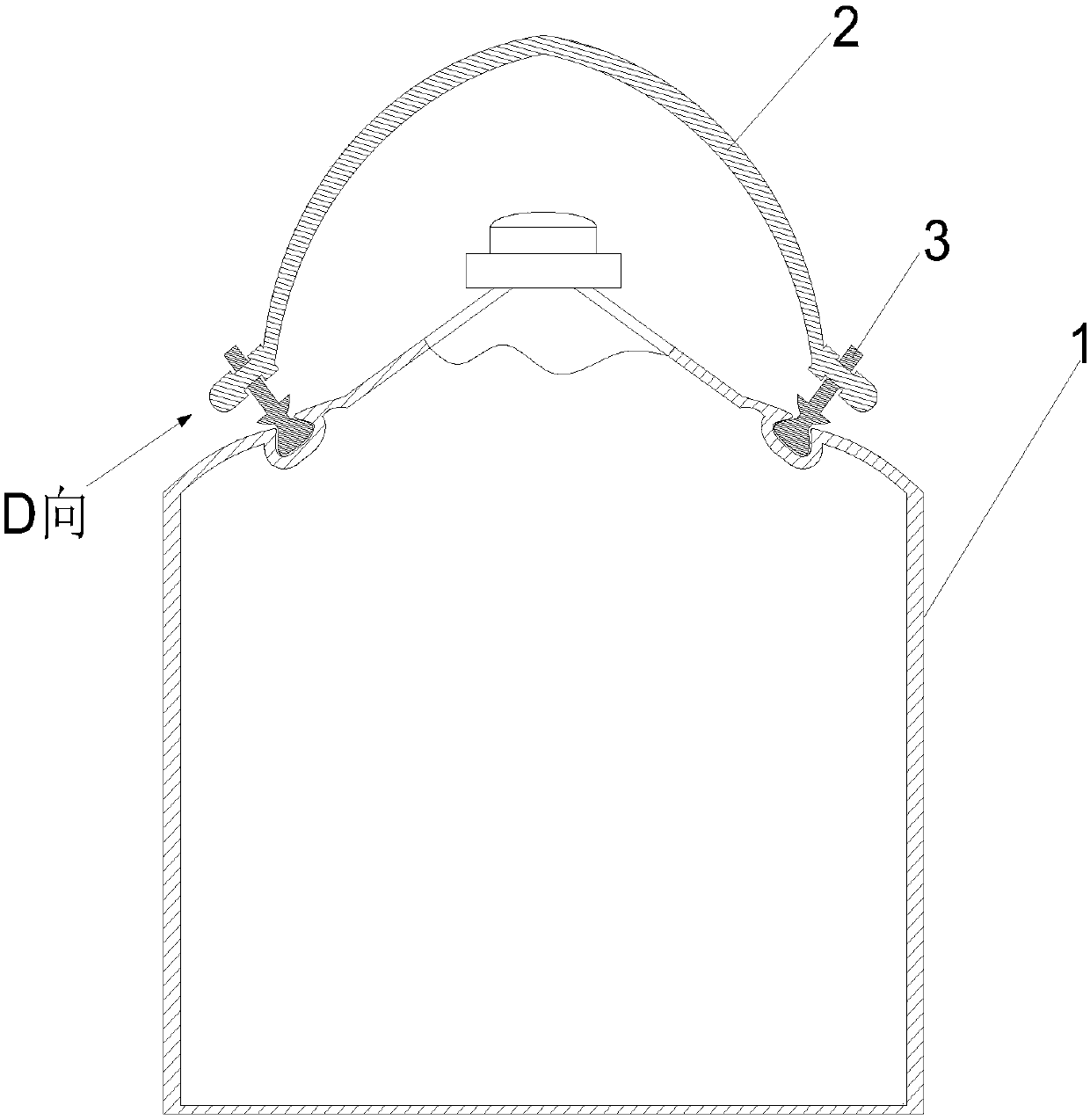

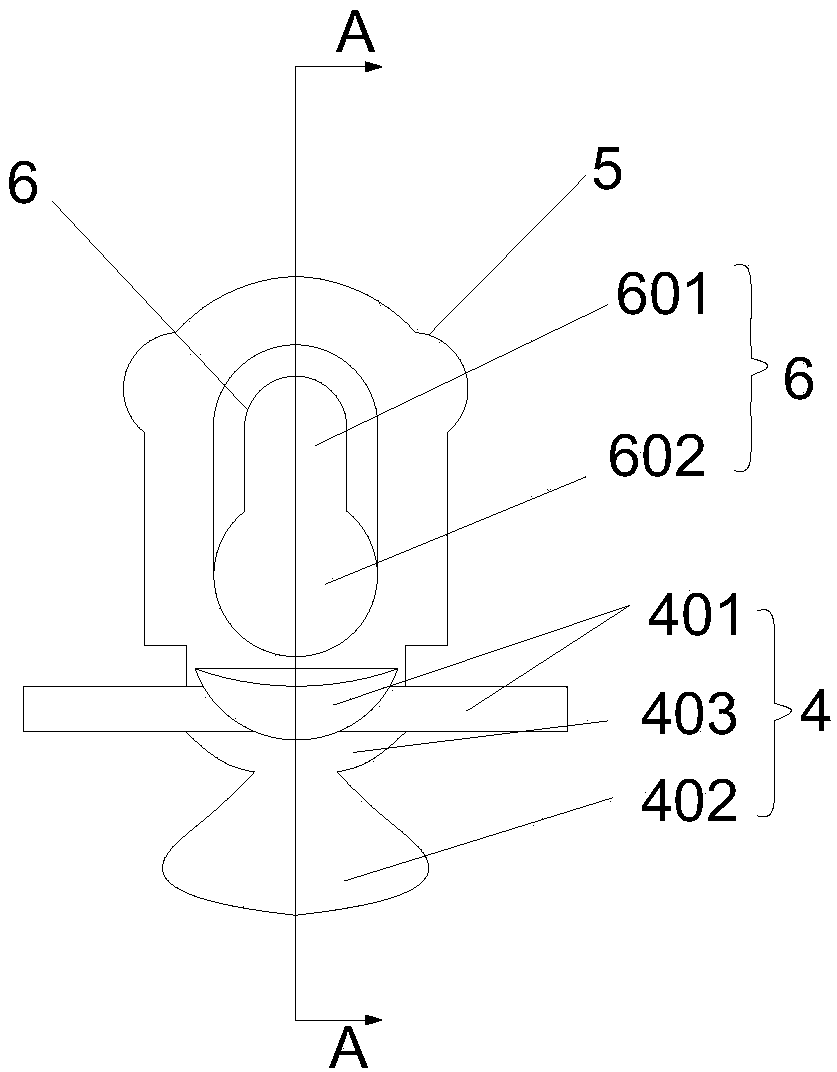

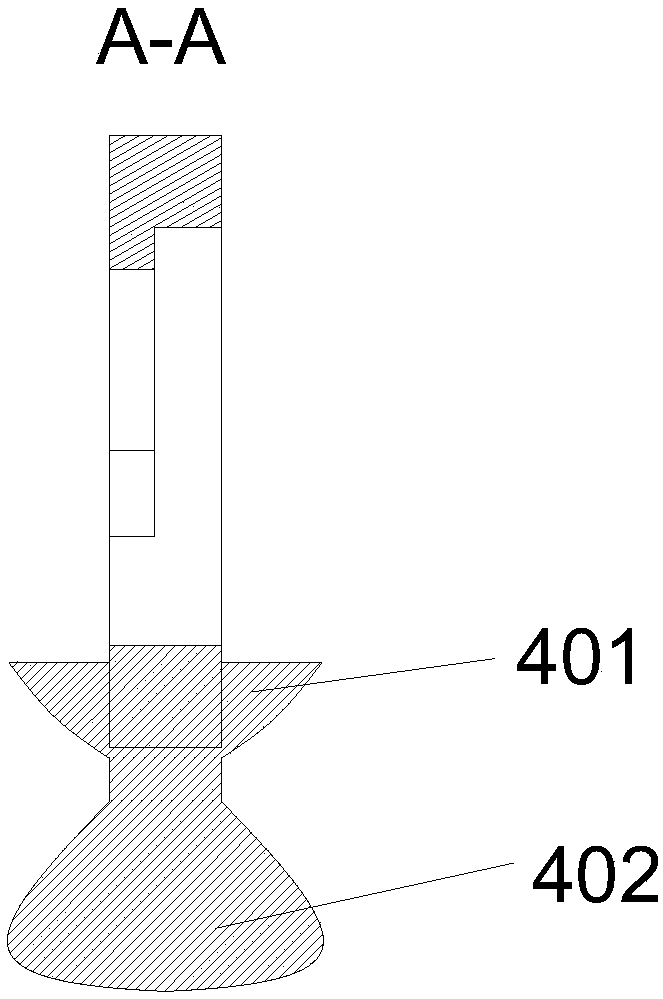

[0027] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a liftable plastic container, including a handle 2, a plastic shell 1 constituting the container body, and at least two handle installations for connecting the two ends of the handle 2 to the plastic shell 1 respectively. Seat 3, each handle mounting seat is partly covered by the side wall of the plastic shell 1, and partially exposed outside the plastic shell 1, and the handle 2 is connected to the handle mounting seat. In this embodiment, the handle mounting seat is partly wrapped in the plastic shell, which is equivalent to directly setting the handle mounting seat on the plastic shell. The invention can effectively improve the load-bearing and stability of lifting, but at the same time, it does not destroy the original sealing performance of the plastic shell.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com