Yellowing-resistant elastic paint and its preparation method, use method and application

A hand-feeling paint and anti-yellowing technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of not being able to meet the yellowing resistance and environmental protection at the same time, and achieve low cost, high drying activity, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In one embodiment, the preparation method of the anti-yellowing paint at least includes the following steps:

[0055] Disperse the weighed film-forming resin, environmental drier, and leveling agent, add matting powder while dispersing, and disperse for 5-10 minutes until the dispersion is uniform, and then add the weighed ultraviolet light absorber to the above-mentioned Disperse in the container for 5-10 minutes until the dispersion is uniform. So far, the preparation of the above-mentioned anti-yellowing paint is completed.

[0056] Specifically, during dispersion treatment, each component is placed in a dispersion container, and dispersed at a stirring speed of 500-1000 r / min.

[0057] The anti-yellowing hand feel paint of the present invention adopts the above preparation method, adopts step-by-step and layered dispersion according to the particle diameters of the matting powder and the ultraviolet light absorber, effectively avoids the phenomenon of uneven disper...

Embodiment 1~3 and comparative example 1~2

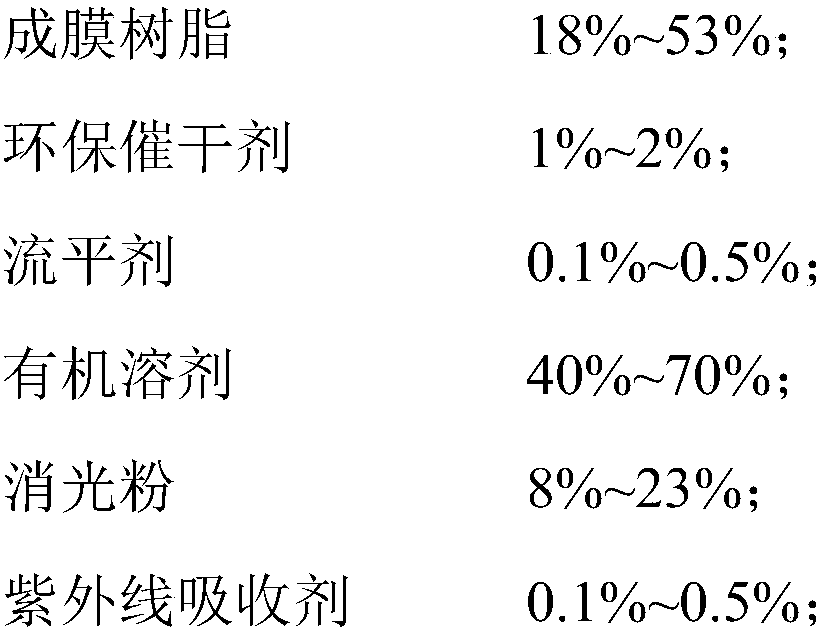

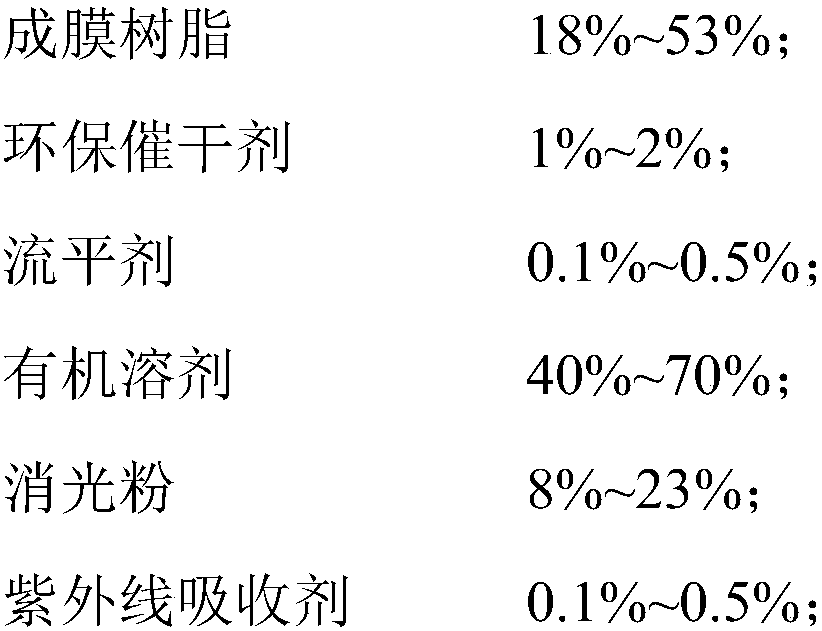

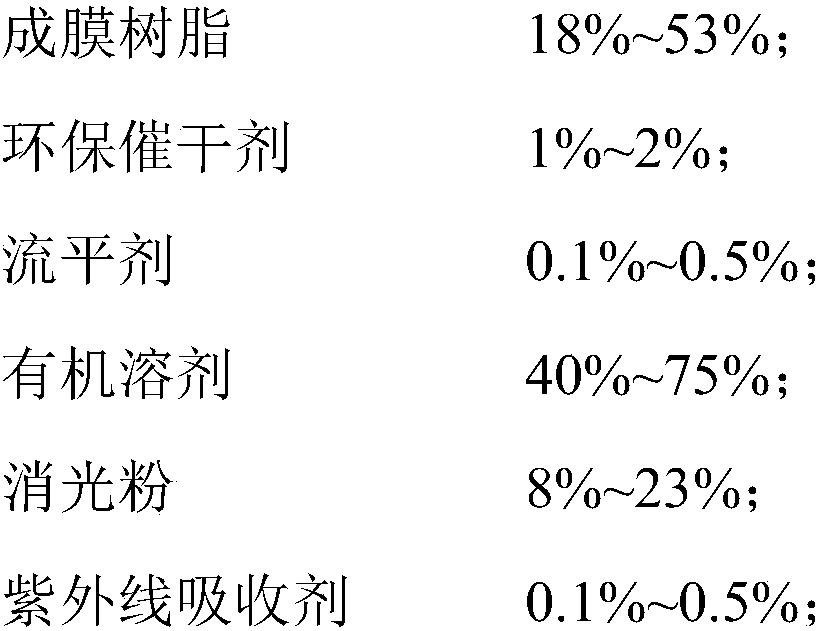

[0068] For convenience of comparison, the formulations of Examples 1-3 and Comparative Examples 1-2 are listed in Table 1.

[0069] The preparation method of the coating of concrete each embodiment and comparative example is:

[0070] According to the formulas of Examples 1-3 and Comparative Examples 1 and 2 in Table 1, add each component in turn and stir evenly to form a mixed coating, dilute with isobutyl acetate, and the weight ratio is A component: curing agent: acetic acid The ratio of isobutyl ester is 100:10~15:20~40.

[0071] Table 1 embodiment 1~3 and comparative example 1~2 formula components

[0072]

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com