Computer readable storage medium and vertical continuous pulse electroplating line applying computer readable storage medium

A storage medium and pulse electroplating technology, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problem of reducing the roughness of the coating on the surface of the plate to be plated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

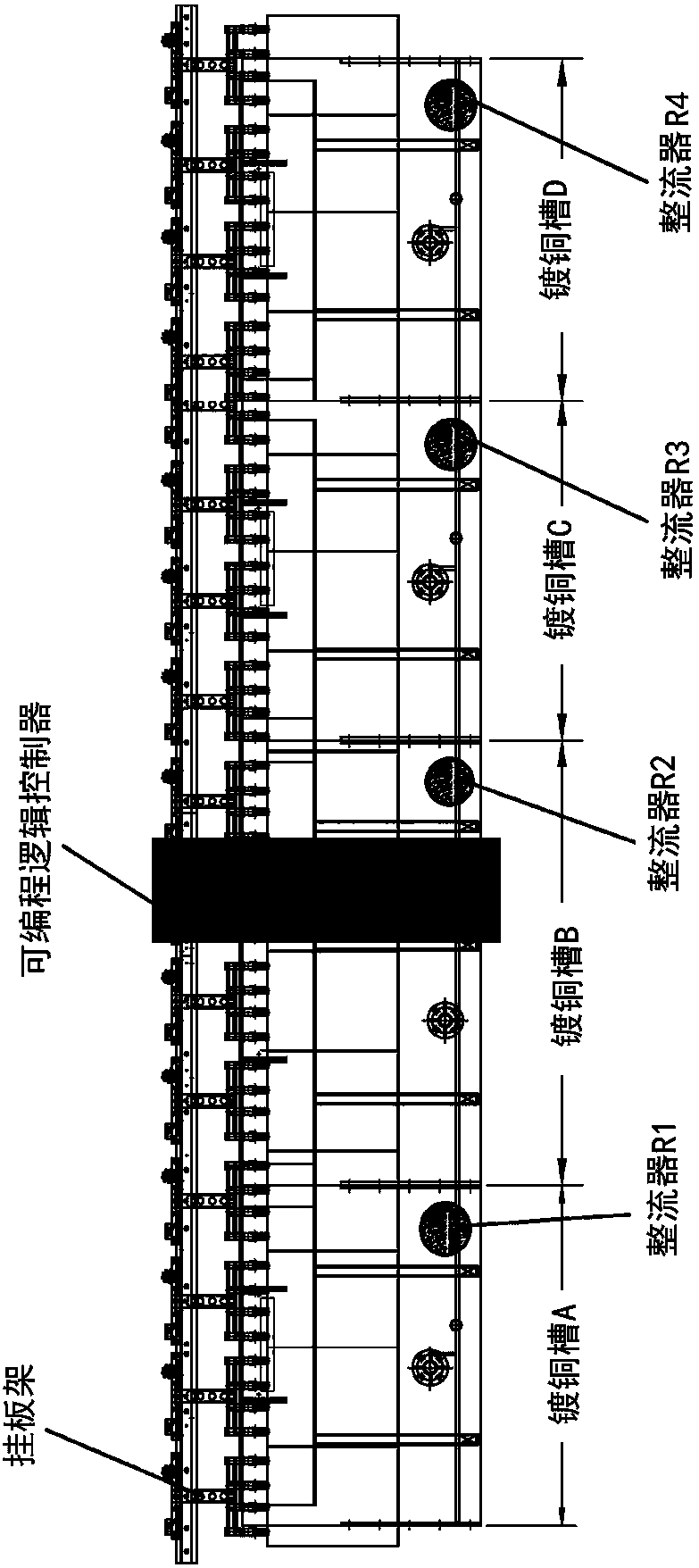

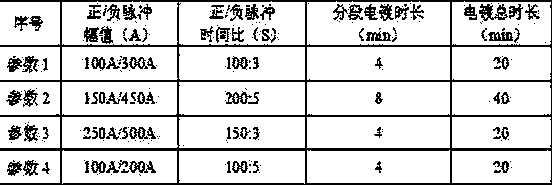

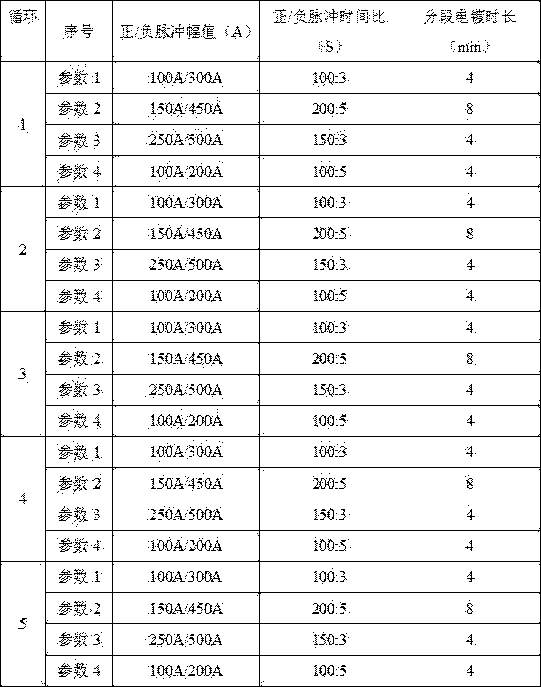

[0021] Such as figure 1 As shown, the vertical continuous pulse plating line is provided with four continuous copper plating tanks A, B, C, D, and each copper plating tank is equipped with a rectifier R1, R2, which is used to adjust the pulse current in the plating tank. R3, R4, there is a programmable logic controller outside the tank body of the copper plating tank B, this programmable logic controller is connected to the rectifiers R1, R2, R3, R4 of each copper plating tank, in the programmable logic control The electroplating parameters and parameter switching time corresponding to the rectifiers R1, R2, R3, R4 are stored in the device, and the pulse current output by the rectifiers R1, R2, R3, and R4 of each electroplating tank can be controlled. The plate to be plated is hung on the hanging plate rack in the electroplating tank of the vertical continuous pulse electroplating line. Under the action of the pulse current output by the rectifiers R1, R2, R3, R4, the plate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com