A method for judging the profile angle of oil casing circular threads

A technology of oil casing and determination method, which is applied in the direction of casing, drill pipe, earthwork drilling and production, etc. It can solve the problem that the thread angle of oil casing is difficult to accurately determine, and achieves easy measurement, accurate reflection, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0022] A method for judging the profile angle of round threads of oil casing pipes, comprising the following steps:

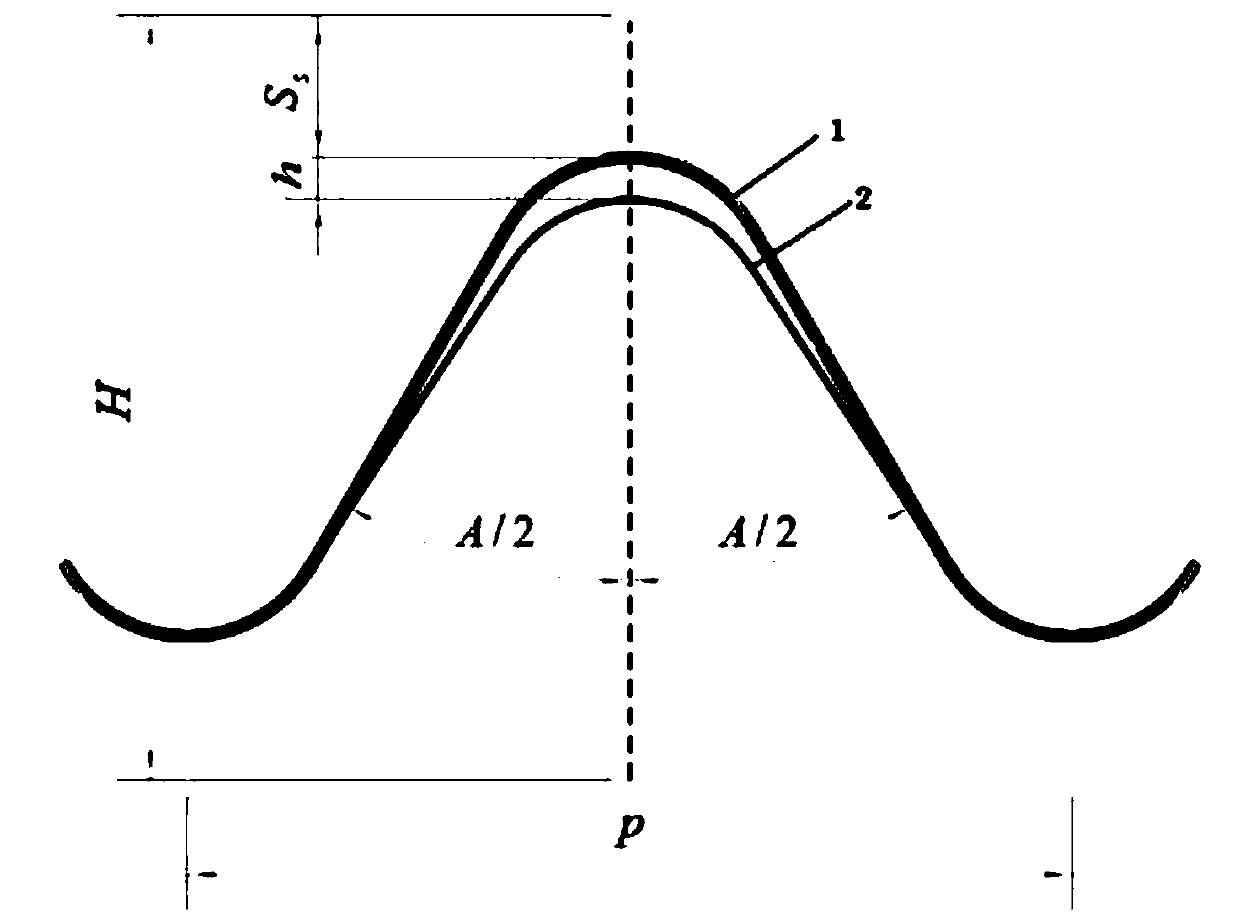

[0023] 1) After the casing thread processing is completed, use the profile height gauge to measure the profile height deviation h of the thread;

[0024] 2) Judgment conditions:

[0025] Among them, H is the theoretical thread height of round thread;

[0026] S s The thread reduction value specified in the standard;

[0027] p is the thread pitch;

[0028] A is the upper limit value of the thread profile angle specified in the standard, and K is the processing correction coefficient;

[0029] 3) When the measured thread profile height deviation h satisfies the judging conditions, it is judged that the thread profile angle is qualified, otherwise it is unqualified.

[0030] The above-mentioned processing correction coefficient K is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com