Nonlinear stiffness isolation system based on hydraulic negative stiffness mechanism

A technology of vibration isolation system and negative stiffness, which is applied in the direction of shock absorbers, mechanical equipment, shock absorber-spring combinations, etc., and can solve problems such as poor structural bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

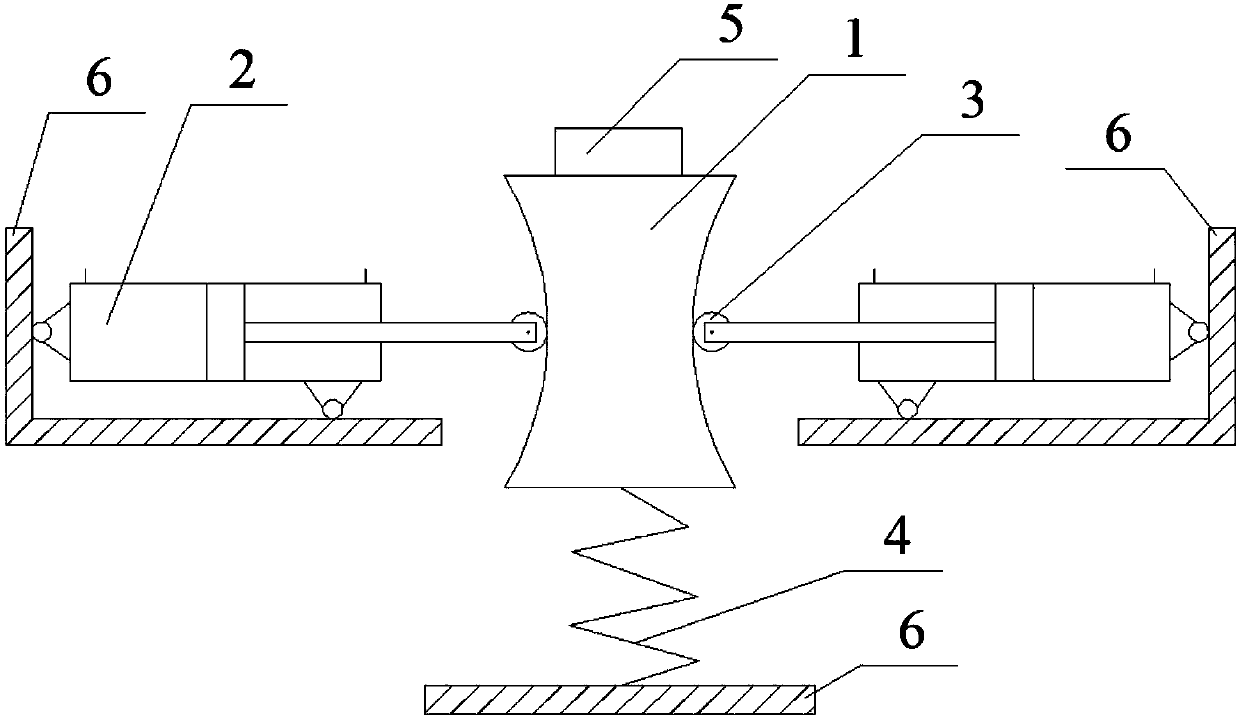

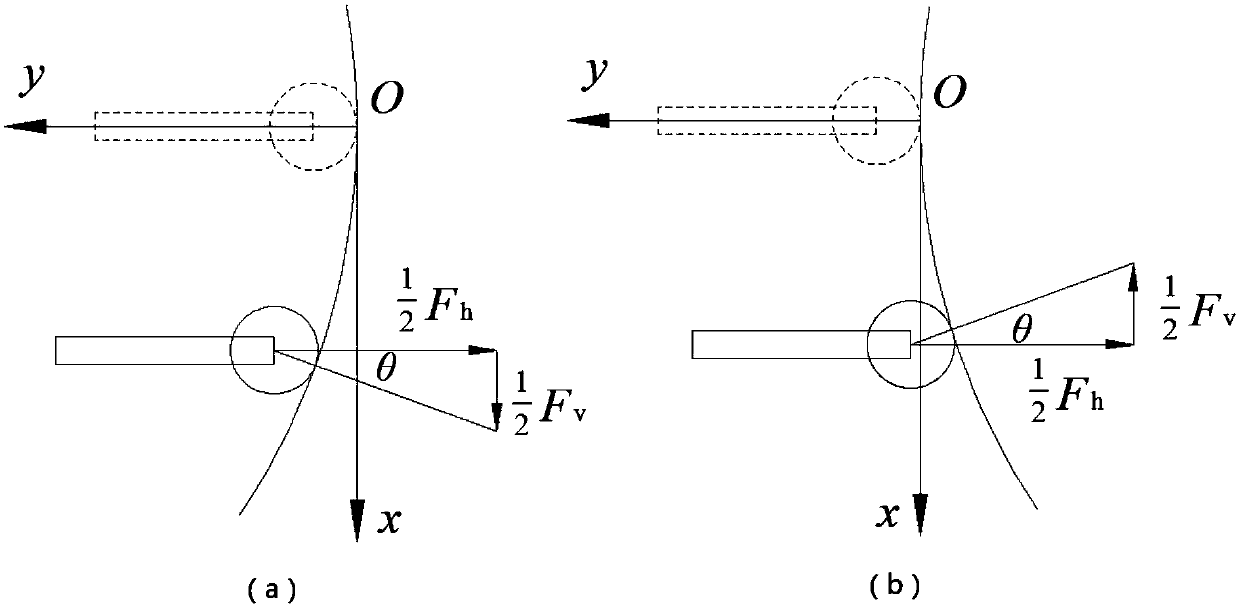

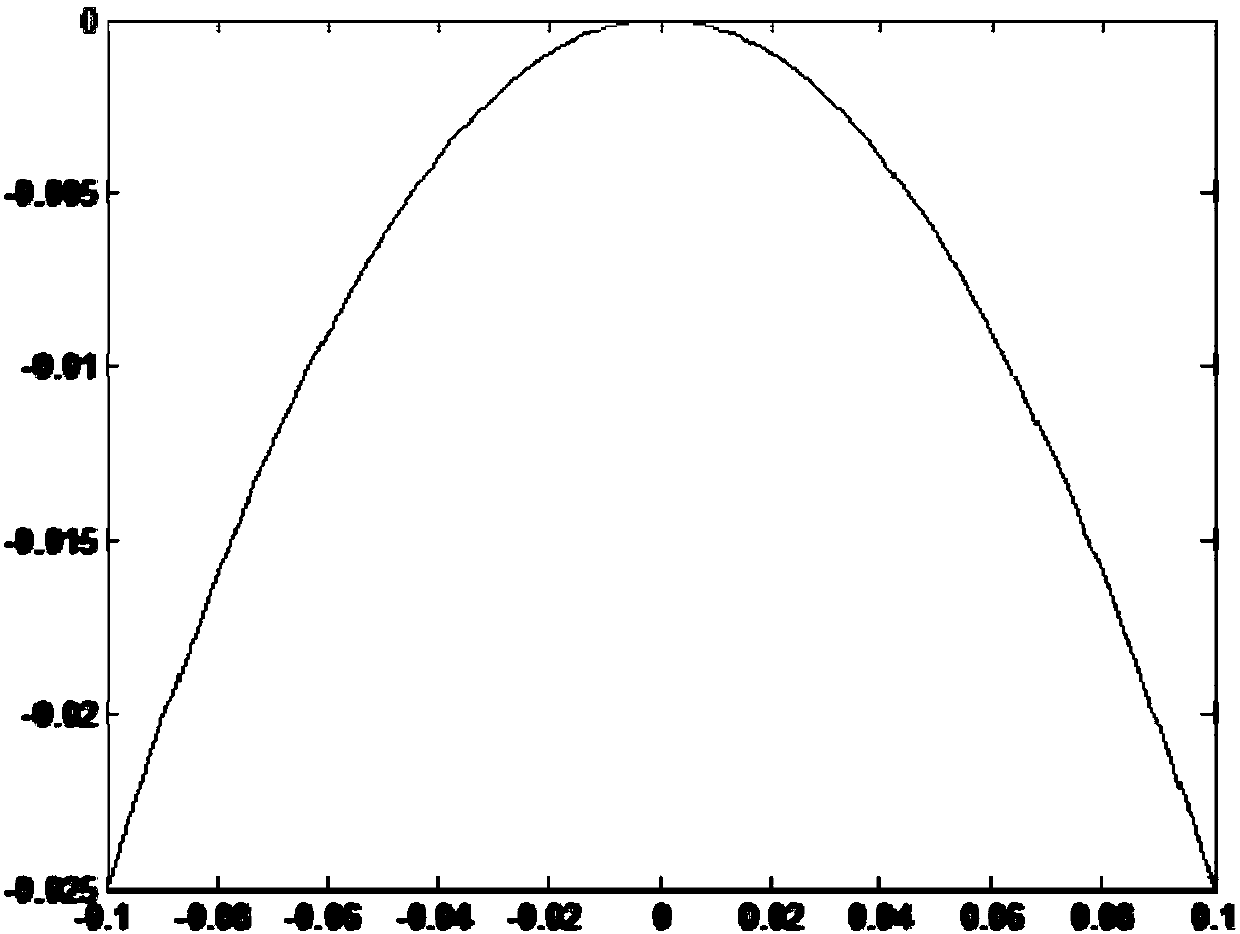

[0031] Such as figure 1 As shown, a nonlinear stiffness vibration isolation system based on a hydraulic negative stiffness mechanism, including a hydraulic negative stiffness mechanism composed of a hydraulic cylinder 2, a rolling ball 3 and a rolling ball slide carrier 1, wherein the rolling ball slide carrier 1 A pair of ball slides are arranged symmetrically along its central axis on the side of the hydraulic cylinder 2. The piston rod of the hydraulic cylinder 2 is hinged to the ball 3. The ball 3 is also against the ball slides and can roll on the ball slides. , the hydraulic cylinder 2 is fixedly connected to the mounting seat 6, and applies a lateral constant hydraulic force to the bearing body 1 of the ball slideway through the ball slideway. The bottom end of the ball slide carrier 1 is also equipped with a vertical positive stiffness spring 4 (in this embodiment 1, the vertical positive stiffness spring 4 is a coil spring among linear springs) that applies a vertical...

Embodiment 2

[0040] Compared with Embodiment 1, most of them are the same, except that the hydraulic negative stiffness mechanism can be provided with two or more, that is, the ball slideway is provided with corresponding two or more groups on the side of the ball slideway carrier 1 , the slideway curves of each group of rolling ball slideways are the same, and each slideway curve is equipped with a hydraulic cylinder 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com