Quasi-zero stiffness metal-rubber composite vibration isolator

A metal rubber, quasi-zero stiffness technology, applied in the functional characteristics of spring/shock absorber, spring/shock absorber, high internal friction spring, etc., can solve the problems of equipment interference, low dynamic stiffness, high static stiffness, etc., and achieve cost The effect of low cost and simple mold processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

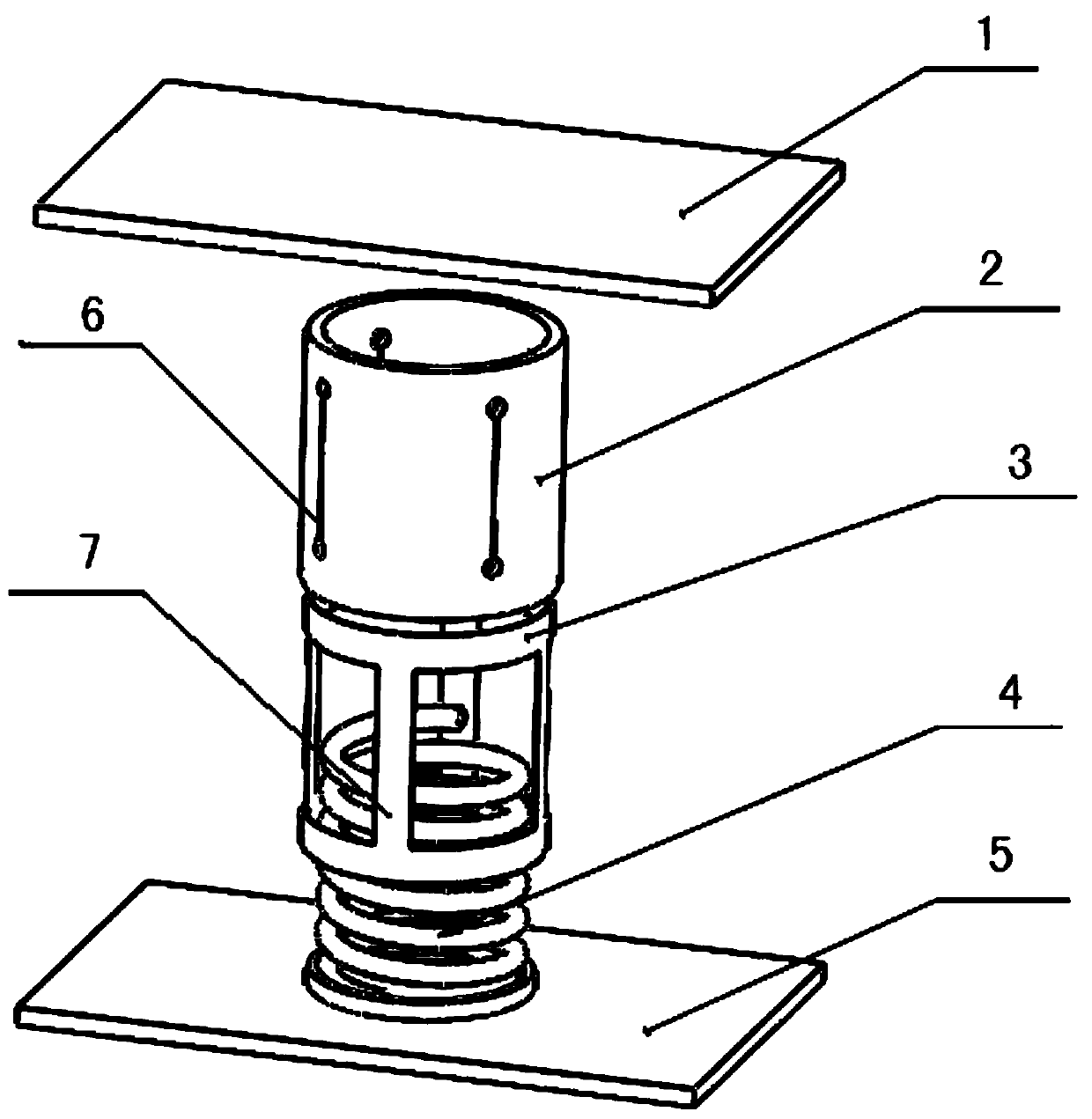

[0034] A quasi-zero stiffness metal-rubber composite vibration isolator, comprising an upper connecting steel plate 1, a metal-rubber composite ring column, a cylindrical helical spring 4 and a lower connecting steel plate 5; the metal-rubber composite ring column is composed of a rubber ring column 2 and a metal skeleton 3 connections, the diameters of the two are the same, and the rubber ring column 2 is formed by pouring vulcanized rubber on the metal skeleton 3; the upper connecting steel plate 1 carries the vibration-isolated object, and the lower connecting steel plate 5 is connected to the foundation; in order to ensure the vibration isolation effect, the insulating The vibrator should be placed at the center of the bottom of the isolator or placed evenly and symmetrically, and the weight of the isolator should not exceed the rated load of the isolator to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com