Eccentric ball valve

An eccentric ball and eccentric technology, which is applied in the direction of valve devices, cocks including cutting devices, engine components, etc., can solve the problems of affecting the sealing performance of the valve core and valve seat, difficult processing of ball valves, and insufficient processing, so as to reduce the processing cost. Difficulty, reduce processing difficulty and processing accuracy, and ensure the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

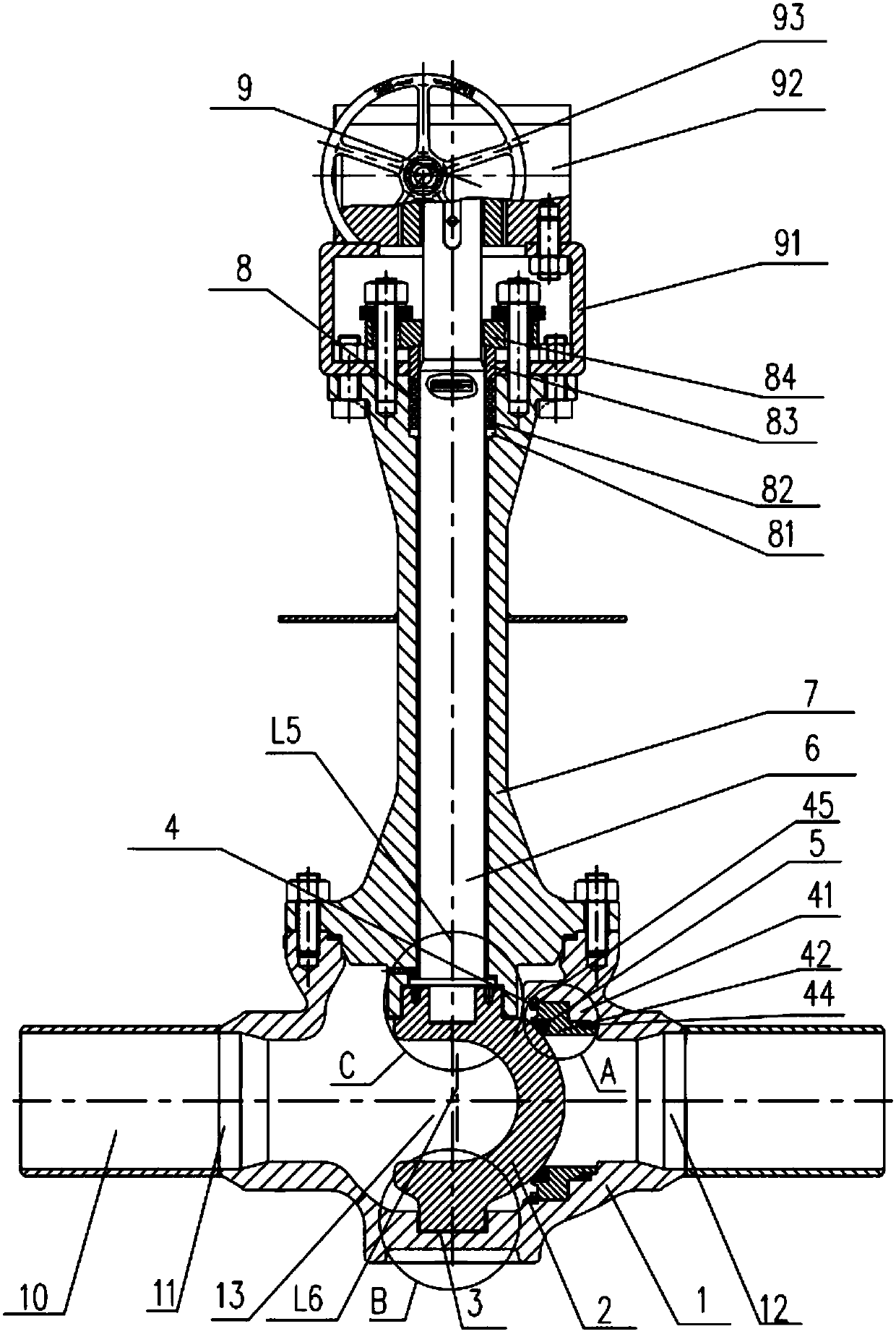

[0059] This embodiment provides an eccentric ball valve, such as figure 1 As shown, it includes a valve body 1 , a valve cover 7 , a valve stem 6 , a valve seat 5 , a hemispherical valve core 2 and a mounting structure 4 .

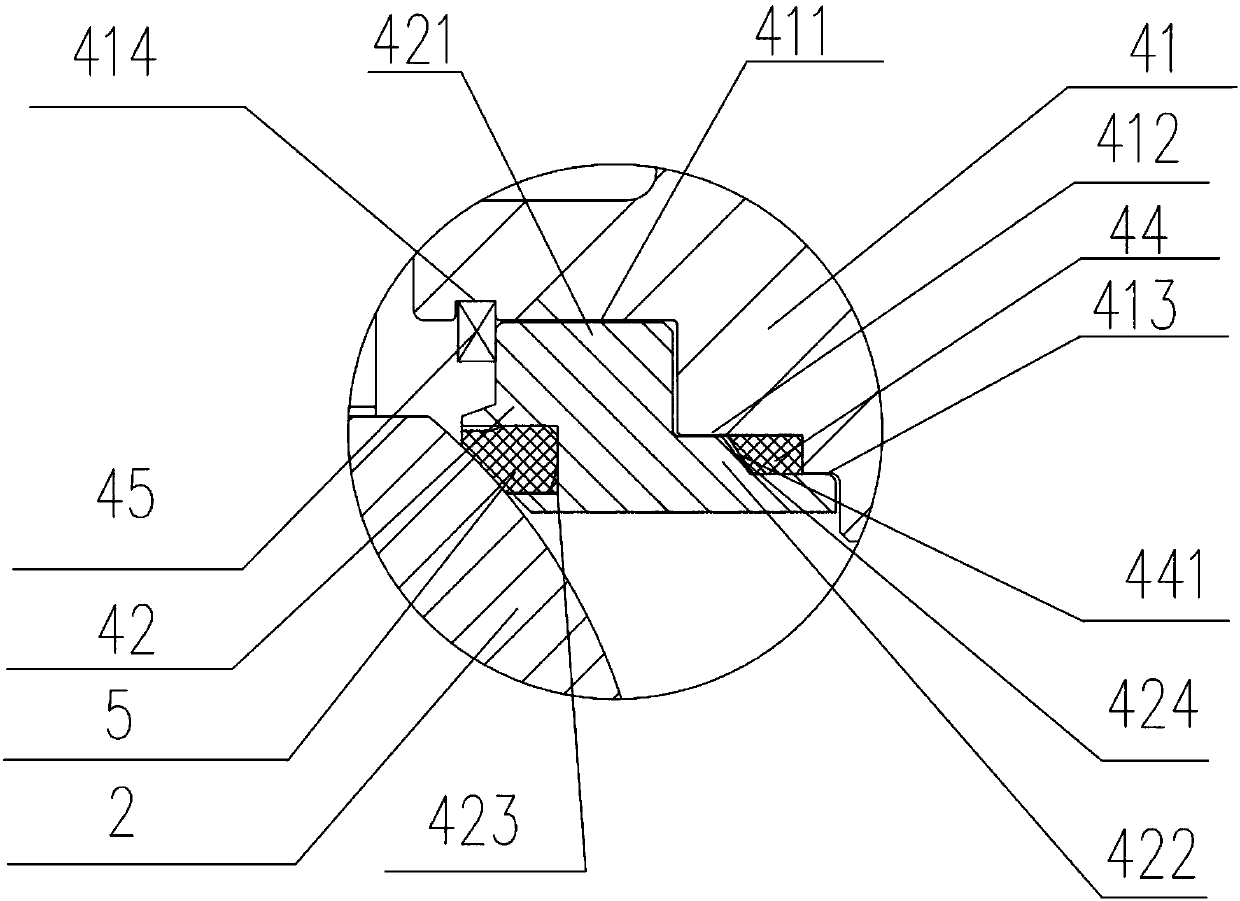

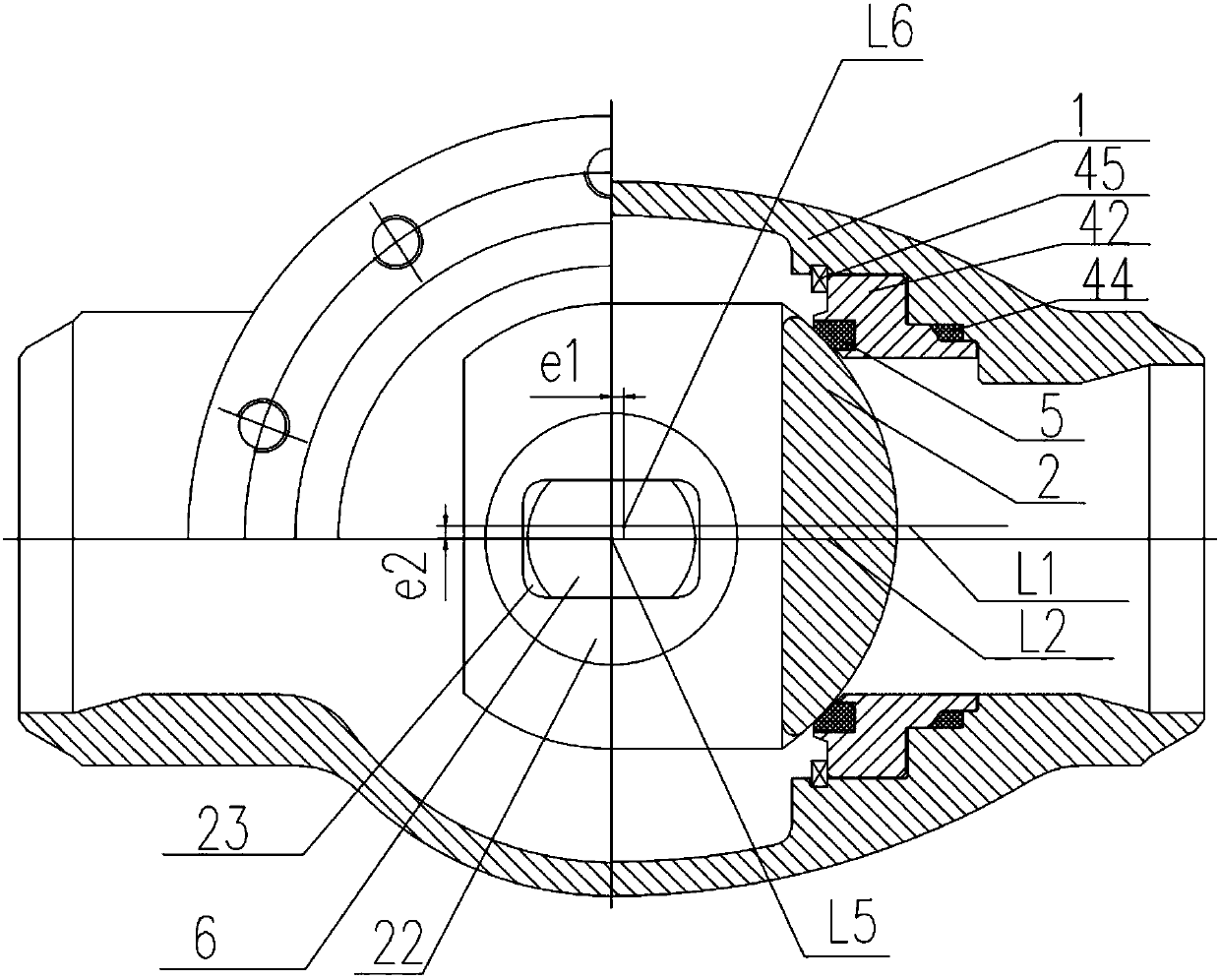

[0060] like figure 1 As shown, the valve body 1 has a top opening, a flow channel 13 extending along its axial direction, and an inlet 11 and an outlet 12 for the medium to flow into and out of the flow channel 13, respectively; the valve cover 7 is sealingly mounted on the top opening of the valve body 1 ; The bottom of the valve stem 6 extends into the flow channel 13 through the valve cover 7, the hemispherical valve core 2 is installed on the bottom of the valve stem 6 and is located in the flow channel 13; The valve seat 5 is eccentrically installed on the valve body through the installation structure 4 and sealed 1 on the inner wall and close to the outlet 12. like image 3 As shown, the rotation centerline L5 of the valve stem 6 is eccentric to t...

Embodiment 2

[0078] This embodiment provides an eccentric ball valve, which is different from the eccentric ball valve provided in Embodiment 1 in that no bearing may be provided between the first protrusion of the valve core 2 and the first groove of the valve body 1, only Depending on its structure and the thrust pad 3 , the first protrusion 21 at the bottom of the valve core 2 is rotatably installed in the first groove 14 through the cooperation between the first protrusion 21 and the first groove 14 . To ensure that the valve core 2 does not deviate from its rotation center, the valve core 2 and the valve seat 5 can be opened or closed normally.

[0079] As a first alternative embodiment, the valve core 2 and the valve body 1 may only be provided with protrusions and grooves, without the thrust pads 3, for installation, and through the cooperation of the first protrusions 21 and the first grooves 14, The first protrusion 21 at the bottom of the valve core 2 is rotatably installed in th...

Embodiment 3

[0086] This embodiment provides an eccentric ball valve. Compared with the eccentric ball valve provided in Embodiment 1 or Embodiment 2, the difference is that the eccentric distance e1 and the eccentric distance e2 are not equal, for example, e1: e2=1:2 or e1 : e2 = 2:1, the specific proportional relationship can be determined according to actual needs, as long as there are these two eccentric distances. At this time, when the valve stem drives the valve core to open, the required rotation angle is greater than three degrees, but regardless of the relationship between the eccentric distance e1 and the eccentric distance e2, the valve core can be opened only by turning the valve core ten degrees, making the valve core 2 and valve seat 5 are quickly disengaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com