A blasting demolition method for building longitudinally inclined and collapsing zone by zone

A building and longitudinal technology, which is applied in the direction of building structure, construction, blasting, etc., can solve the problems of insufficient crushing, high cost, and large vibration, so as to reduce blasting collapse vibration, eliminate shear and bending strength, reduce The effect of crushing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

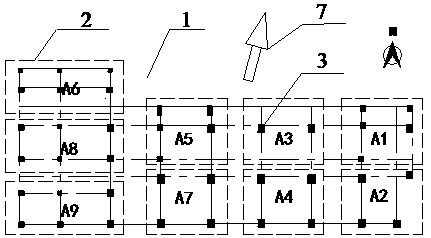

[0044] A certain 17-storey building is a special-shaped frame concrete structure with a length of 48m, a width of 19m at the east end, a width of 25m at the west end, and a height of 63.2m. It is demolished by adopting the blasting demolition method of longitudinally inclined and zone-by-zone collapse of the present invention. The specific steps are as follows:

[0045] (1) According to the layout of the building figure 1 , it can be seen that the size of the load-bearing structure of the building varies greatly, and the spatial distribution is irregular, with a total area of about 1178.5m 2 , the total mass is about 15839t, and the center of gravity is about 28m;

[0046] (2) The north side of the building is relatively open and there is enough collapse site, so the direction of collapse is determined to be 7 to the north;

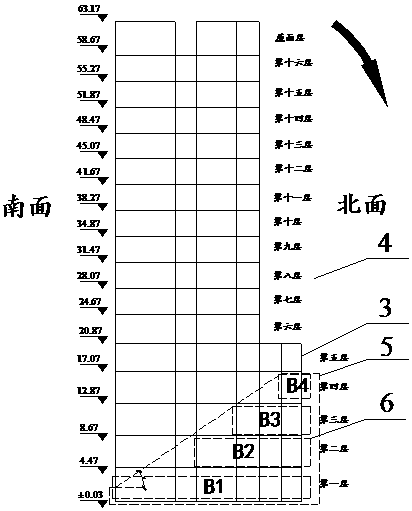

[0047] (3) The height of the blasting gap 5 is determined to be 10.5m at the east end and 13.8m at the west end. gap range;

[0048] (4) According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com