Method for wastepaper deinking and pulping

A technology for deinking and pulping waste paper, which is used in the processing of waste paper, paper making, paper recycling, etc. It can solve the problems of low paper whiteness, high water consumption and high dustiness, and achieve high opening ratio, low operating costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

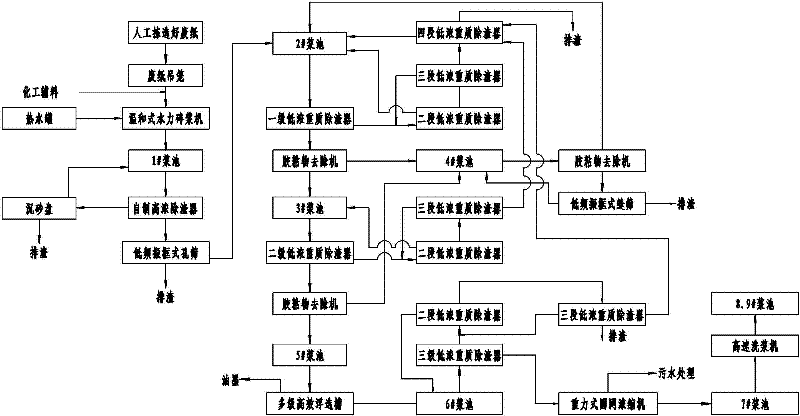

[0049] Such as figure 1 Among them, a waste paper deinking pulping method comprises the following steps:

[0050] 1) The step of pulping with a high-consistency hydraulic pulper; after manual selection, the waste paper is hoisted by a crane and put into the high-consistency hydraulic pulper. After adding hot water and chemical auxiliary materials, it is gently crushed and put into Enter 1# slurry pool.

[0051] 2) The step of removing impurities with high-consistency slag remover and low-frequency vibrating frame-type hole screen; the slurry in the 1# slurry tank is pumped into the high-concentration slag remover, and the tailings enter the settling pan to sink heavy impurities such as staples Back to the 1# slurry tank to form a loop. Most of the slurry enters the low-frequency vibrating frame hole screen, and after screening out impurities such as plastic filaments, it enters the 2# slurry pool.

[0052] 3) Steps to remove impurities with multi-stage multi-stage low-concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com