Preparation method of copy paper

A technology for copying paper and waste paper, applied in the field of papermaking, can solve the problems of affecting pulping quality, insufficient disintegration of waste paper, etc., and achieves the effects of simple structure, easy realization, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

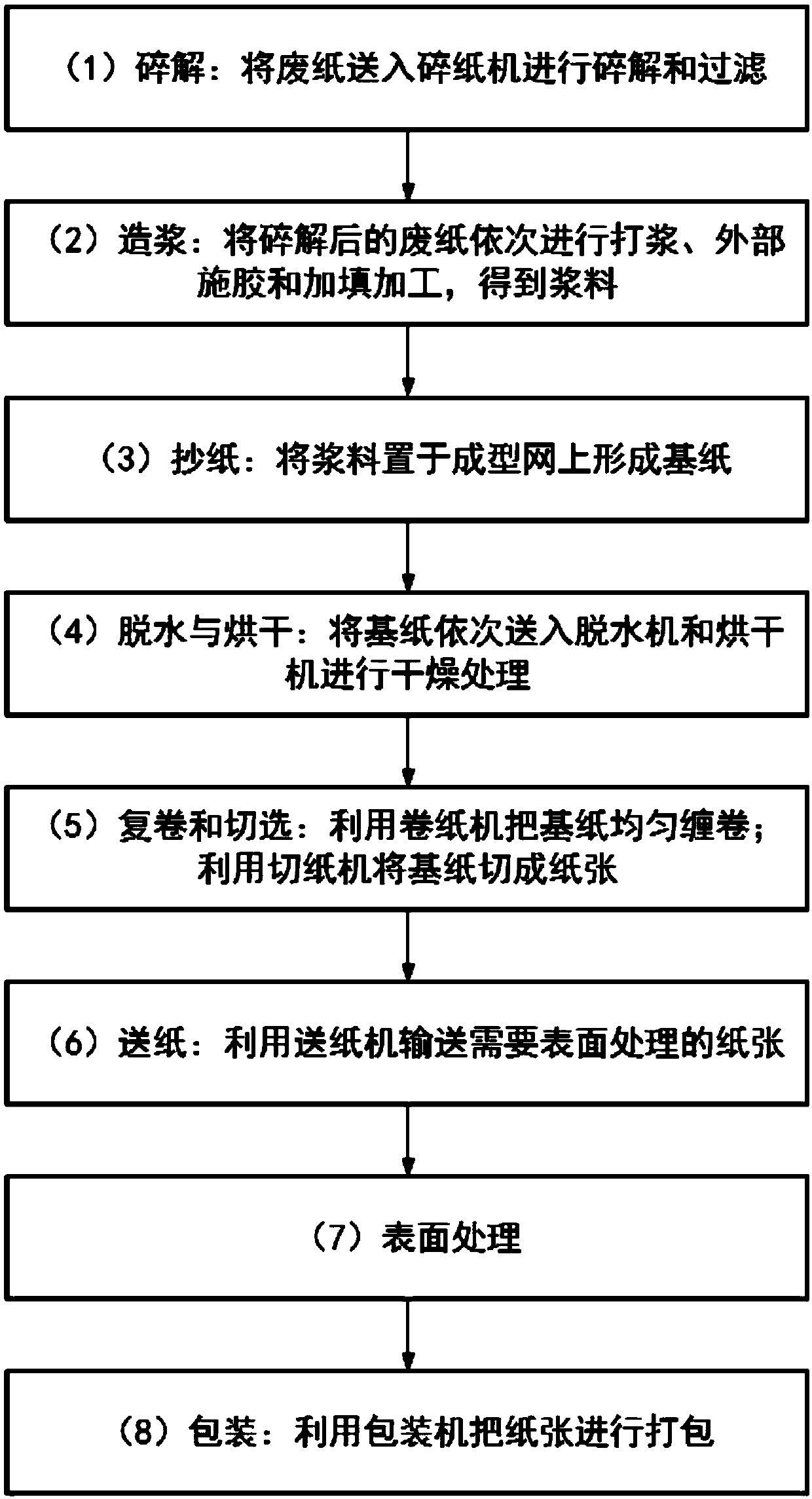

[0022] see figure 1 and figure 2 , the preparation method of a kind of copy paper of the present embodiment, comprises the following steps: (1) shredding: waste paper is sent into shredder to shred and filter; (2) pulping: waste paper after shredding Sequentially carry out beating, external sizing and filling processing to obtain slurry; (3) papermaking: put the slurry on the forming wire to form the base paper; (4) dehydration and drying: send the base paper to the dehydrator and Drying machine for drying treatment; (5) Rewinding and cutting: use the winder to wind the base paper evenly; use the paper cutter to cut the base paper into paper; (6) paper feeding: use the paper feeder to transport the required Surface-treated paper; (7) surface treatment; (8) packaging: use a packaging machine to pack the paper;

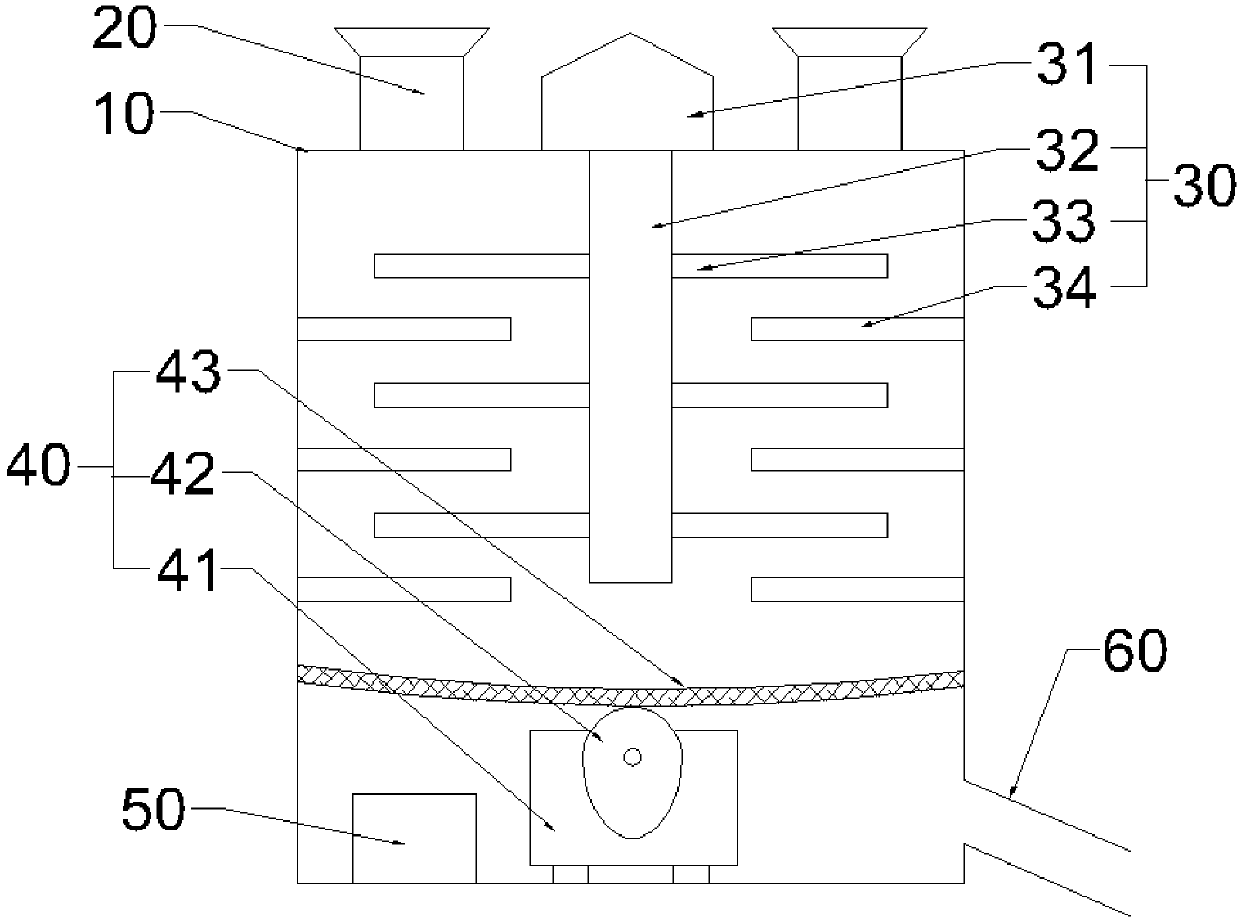

[0023] The paper shredder in the step (1) includes a body 10, a feed barrel 20 arranged on the top of the body, an agitating mechanism 30 arranged in the body, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com