Electrophoretic coating simulation ultrafiltration device and application thereof

An electrophoretic coating and ultrafiltrate technology, applied in electrolytic coatings, ultrafiltration, electrophoretic plating, etc., can solve the problems of bath parameter imbalance, loss, and inability to accurately solve the appearance defects of the coating film, so as to improve the appearance and the method is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

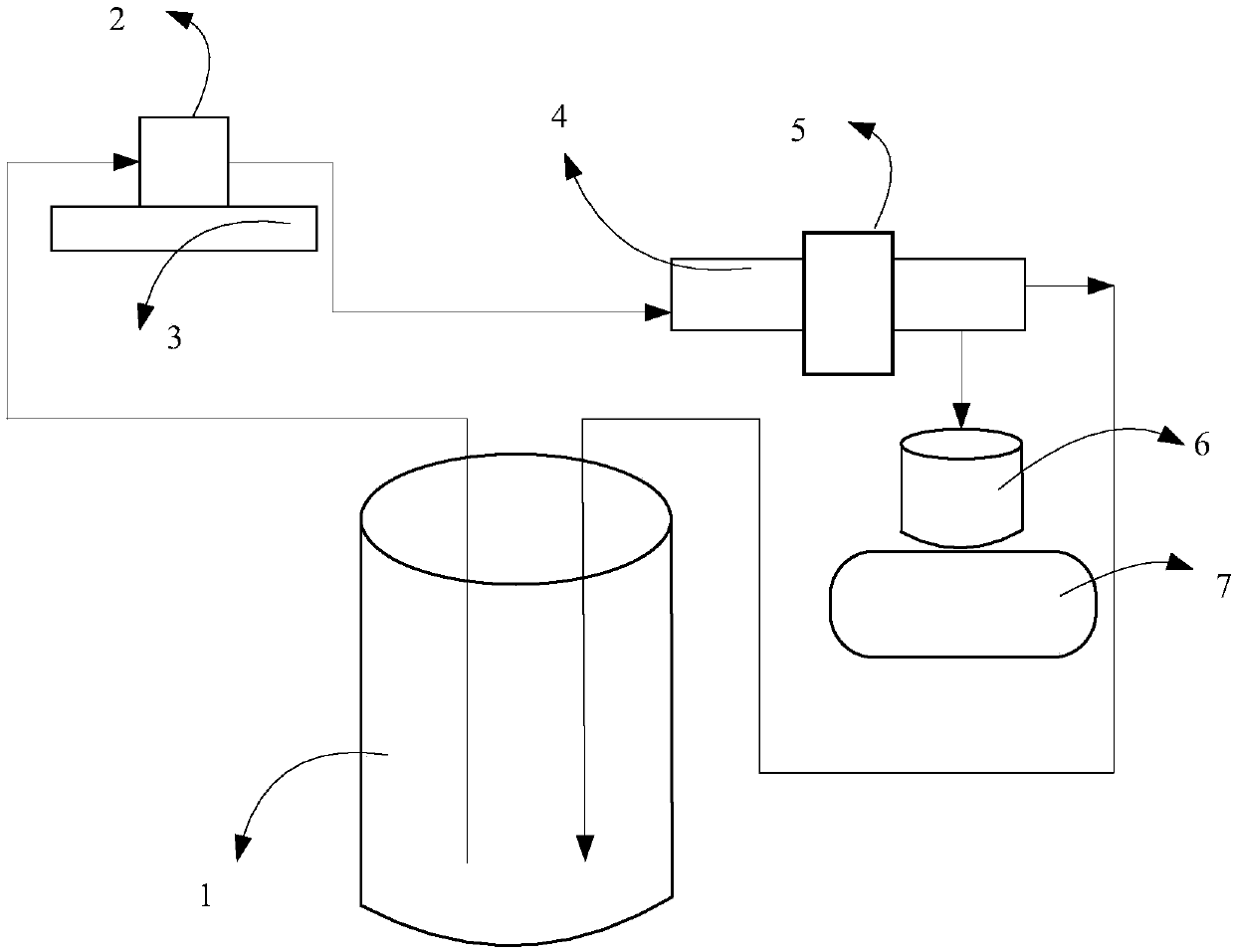

[0047] A kind of electrophoretic coating simulation ultrafiltration device, please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the electrophoretic paint simulation ultrafiltration device of the present embodiment, including an electrophoretic paint holding device 1, a magnetic circulation pump 2, an ultrafiltration device 4 and a holding ultrafiltrate device 6; the electrophoretic paint holding device 1 The outlet is connected to the inlet of the magnetic circulation pump 2, and the outlet of the magnetic circulation pump 2 is connected to the inlet of the ultrafiltration device 4; the ultrafiltration device 4 has two outlets, one of which is connected to the electrophoretic coating The inlet of holding device 1 is connected, and another outlet of described ultrafiltration device 4 leads in the described holding ultrafiltrate device 6; Described magnetic circulation pump 2 is positioned on support 3, and described ultrafiltration device 4 uses ...

Embodiment 2

[0072] Production site electrophoresis tank liquid weight is 220000kg, on-site car body paint film appearance is bad, get on-site tank liquid 4kg and utilize the method for ultrafiltration of the present invention to carry out ultrafiltration experiment, utilize electrophoresis device to carry out coating film preparation; Utilize roughness meter to measure coating film roughness to synthesize Judging the improvement of the appearance of the electrophoretic coating film. Specific steps are as follows:

[0073] 1, get 4kg electrophoretic paint, utilize electrophoretic apparatus to carry out coating film preparation; Use electrophoretic paint simulation ultrafiltration device of the present invention to ultrafilter 1kg UF liquid, the ultrafiltrate is numbered as 1#;

[0074] 2. Add 1kg of pure water to the electrophoretic coating, and use the electrophoresis instrument to prepare the coating film; then ultrafilter 1kg of UF liquid, and number the ultrafiltrate as 2#;

[0075] 3...

Embodiment 3

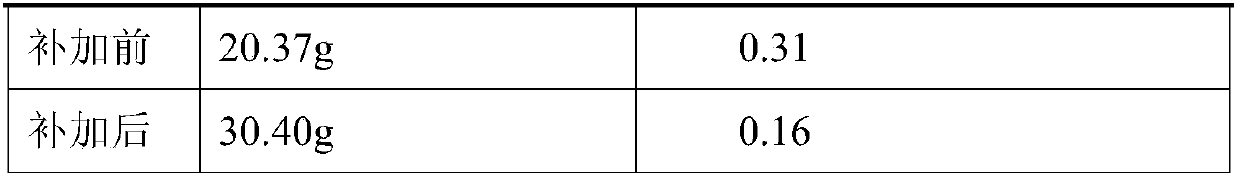

[0091] As can be seen from Example 1 and Example 2, the loss of small molecule resin in the electrophoresis tank can be obtained by the method of the present invention. The small molecule resin content of the new configuration coating of the same type is 30.40g, and the small molecule resin content of the coating with poor appearance is 30.40g. The resin content is 20.37g. Calculate the amount of small molecule resin that needs to be added. After the replenishment cycle is stable, the electrophoretic coating film is prepared again, and the roughness of the coating film appearance is measured. The obtained data are shown in Table 4:

[0092] Table 4

[0093]

[0094]

[0095] Ra is the value directly measured by the roughness meter, the smaller the value, the better the appearance of the coating film.

[0096] Illustrate by embodiment 3, after carrying out the simulation ultrafiltration of coating and the calculation quantitative addition of small molecular resin content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com