Cleaning device of spray head of ink-jet printer

The technology of an inkjet printer and a cleaning device, which is applied in the direction of printing, etc., can solve the problems affecting the cleaning quality of the nozzle of the inkjet printer, affecting the normal operation of the inkjet printer, and damage to the smooth surface of the inner wall of the nozzle, so as to avoid contamination of the outer wall of the nozzle, Improve the cleaning speed and cleaning quality, avoid the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

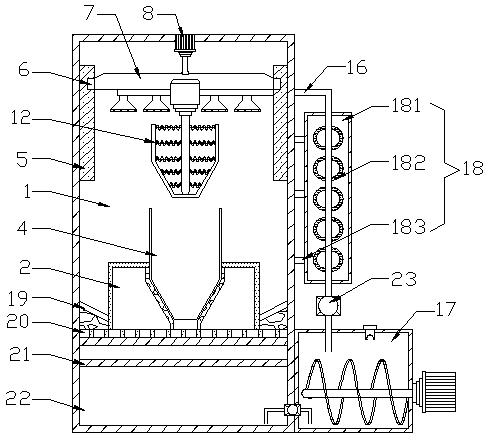

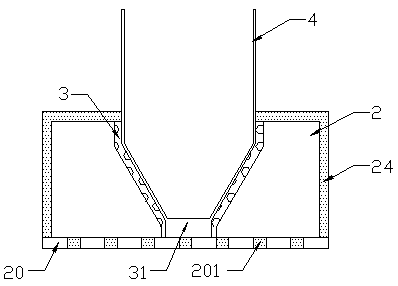

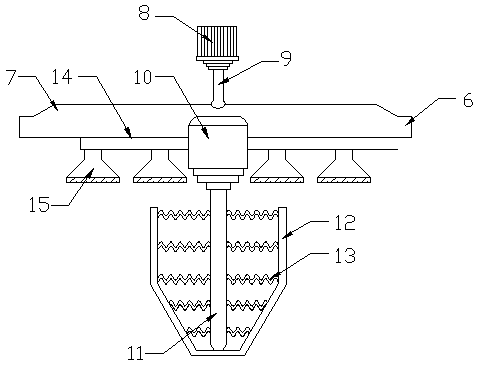

[0021] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a cleaning device for the nozzle of an inkjet printer, including a cleaning device main body 1 and a cleaning table 2, and the cleaning table 2 is installed on the bottom of the cleaning device main body 1, and also includes a nozzle fixing device. Groove 3, nozzle 4, side rail 5, sliding seat 6, moving beam 7, cylinder 8, piston rod 9, cleaning motor 10, rotating shaft 11, cleaning brush 12 and shower pipe 14, described cleaning table 2 is installed with Nozzle fixing groove 3, nozzle 4 is installed inside the nozzle fixing groove 3, side guide rails 5 are installed on both sides of the main body 1 of the cleaning device, and a moving beam 7 is slidably connected to the side guide rail 5 through a sliding seat 6 , the top of the moving beam 7 is connected with the cylinder 8 installed on the main body 1 of the cleaning device through the piston rod 9, the bottom of the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com