Detergent case and washing machine and method for controlling detergent release

A detergent box and detergent technology, applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of water and electricity consumption, reduce the service life of sensors, and untimely detection, so as to avoid repeated feeding and avoid The effect of poor washing effect and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

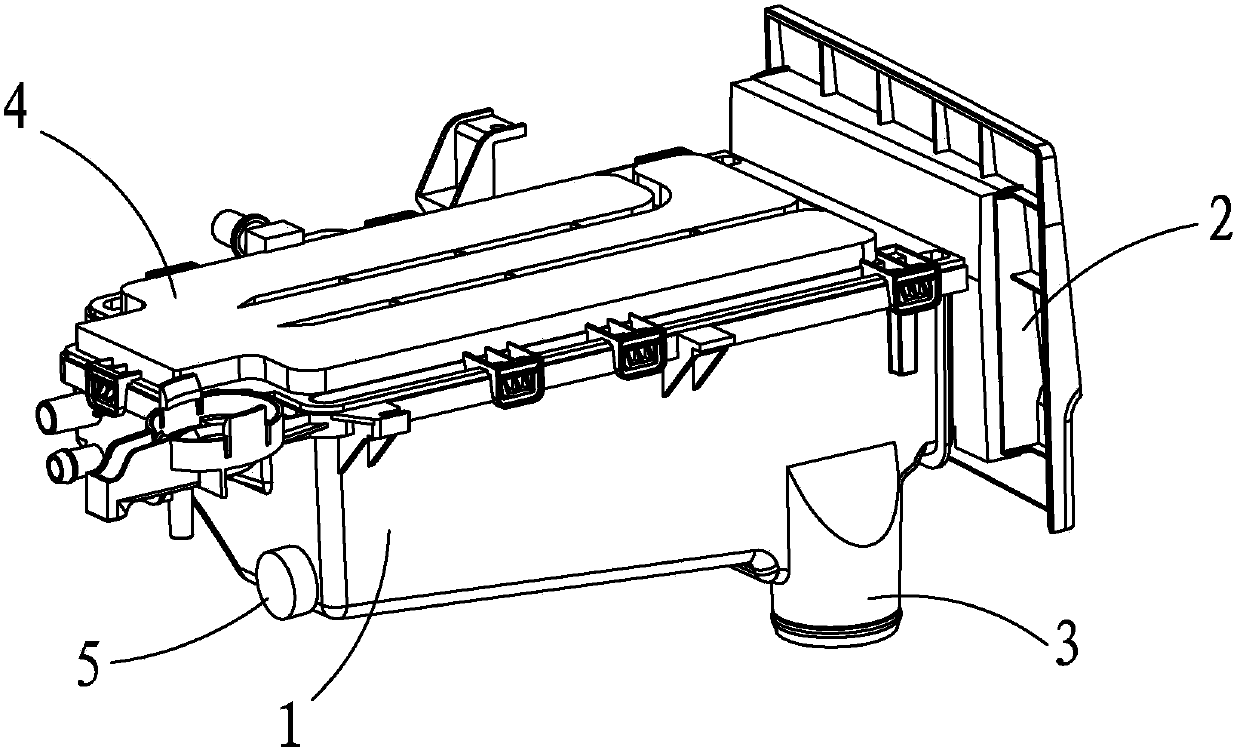

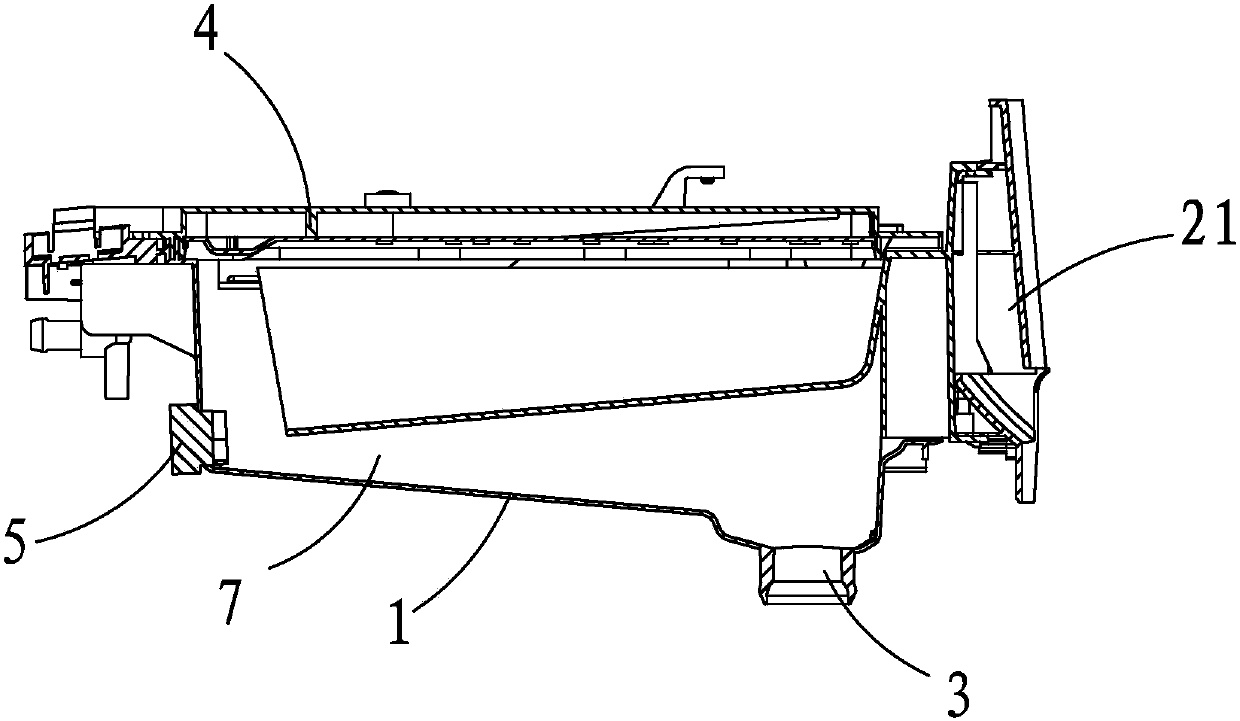

[0031] The invention provides a detergent box, such as figure 1 and figure 2 As mentioned above, it includes a box body 1, a drawer 2 and a controller. The bottom surface of the box body 1 is provided with a water outlet 3, and the front end of the box body 1 is provided with an opening, and the rear end of the drawer 2 is inserted into the box body 1 through the opening. The front end of 2 is provided with a drawer handle 21, and the drawer handle 21 is exposed outside the box body 1. The drawer 2 is provided with a manual feeding cavity 22 and an automatic feeding chamber 24. The drawer 2 is also provided with an upper dissolving channel, and the box body 1 is also provided with a The lower dissolving channel, the manual feeding chamber 22, the upper dissolving channel, the lower dissolving channel and the water outlet 3 are connected in sequence, and the detergent box is provided with a detection electrode 5 for detecting whether there is detergent and dissolved. The dete...

Embodiment 2

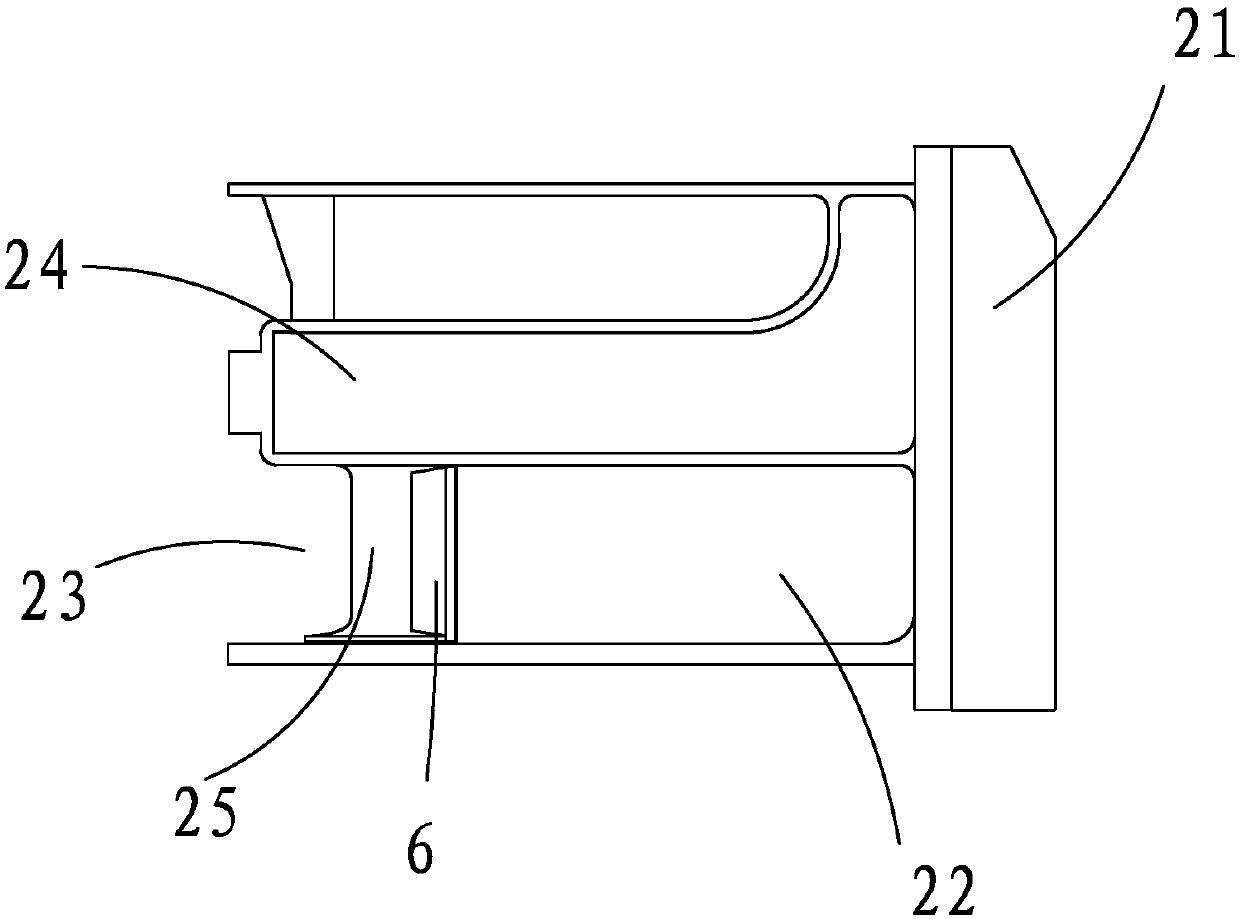

[0043] This embodiment provides a detergent box. The detection electrode 5 is arranged on the drawer 2. Specifically, the detection electrode 5 is fixedly connected to the bottom surface of the drawer 2. The box body 1 is provided with a conductive piece connected to the controller. When the drawer 2 is inserted into the When the box body 1 is in place, the detection electrode 5 is connected to the conductive member. The detection electrode 5 includes a pair of oppositely arranged positive electrode pieces 51 and negative electrode pieces 52. The positive electrode pieces 51 and the negative electrode pieces 52 pass through the bottom surface of the drawer 1 and extend into the communication opening 23. A gap 53 is provided between the positive electrode sheet 51 and the negative electrode sheet 52 for the liquid at the communication port 23 to flow through. The detection electrode 5 is connected to the conductive part, and the controller can monitor whether there is detergent ...

Embodiment 3

[0049] This embodiment provides a washing machine, which includes an inner tub and an outer tub, and further includes the detergent box of any one of the above embodiments, where the detergent box is located above the outer tub and communicates with the outer tub through a water outlet. By detecting the output voltage of the liquid in the detergent box through the detection electrode 5, it is accurately determined whether the detergent is put in and whether it is dissolved, so that the automatic feeding system can be started in time, and the intelligence of the whole washing machine is further improved.

[0050] Refer to Embodiment 1 for other undescribed structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com