Lifting straddle type monorail turnout

A straddle-type monorail and lift-type technology, which is applied in the direction of tracks, locking mechanisms for turnouts, roads, etc., can solve problems such as slow running speed, long turnouts, and easy to be affected by the environment, so as to increase the speed of beam changing and reduce the The effect of friction consumption and smooth beam change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

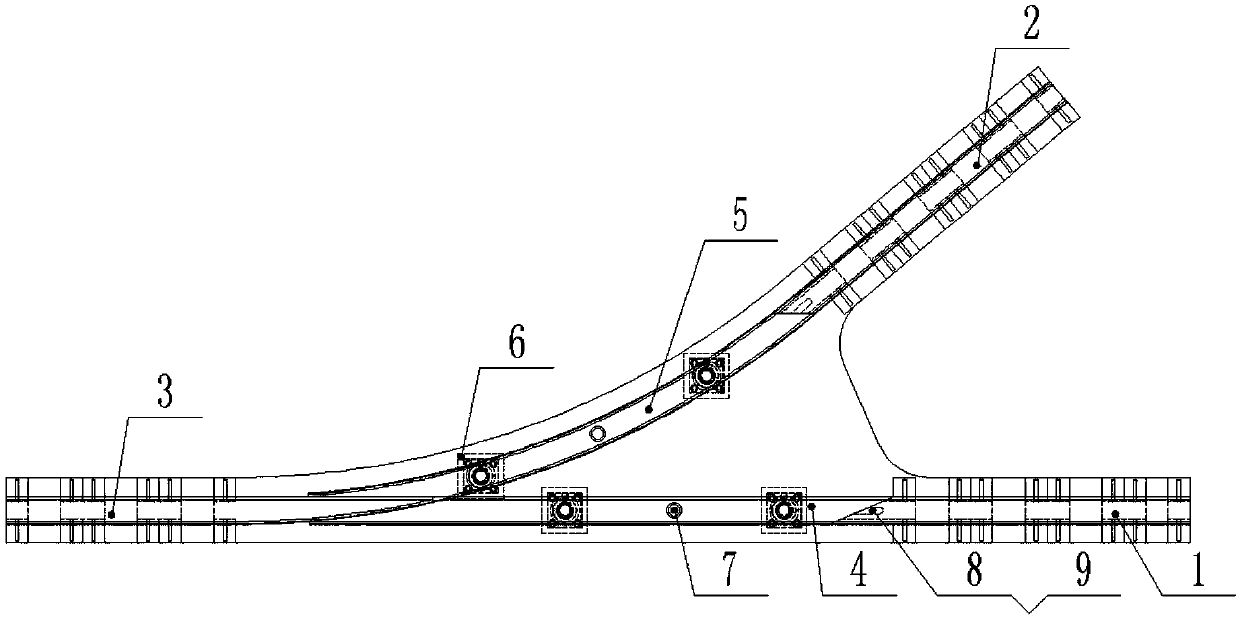

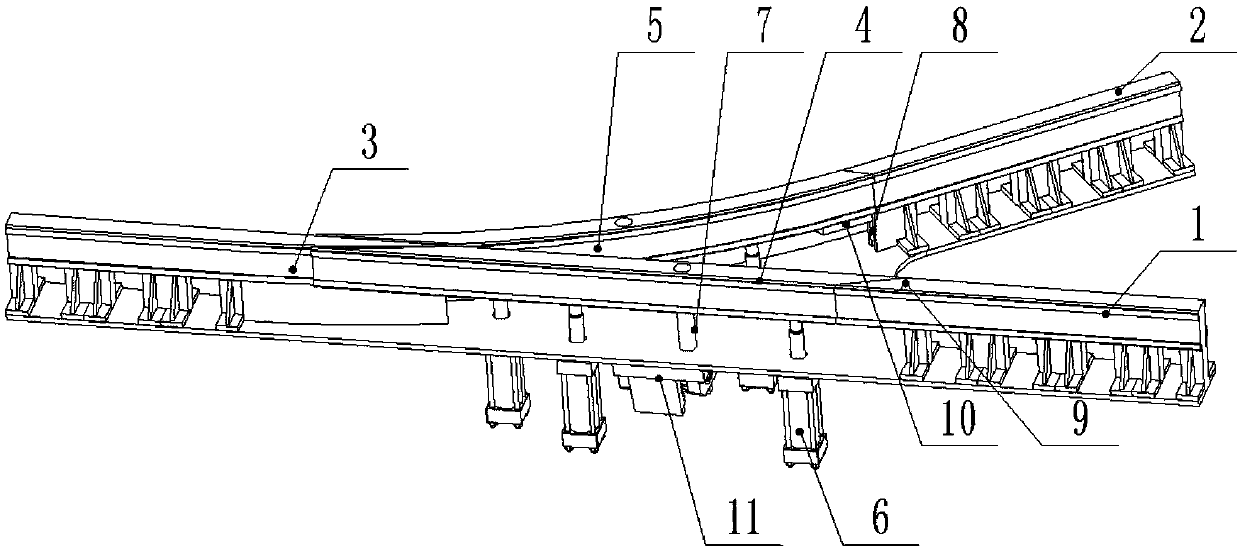

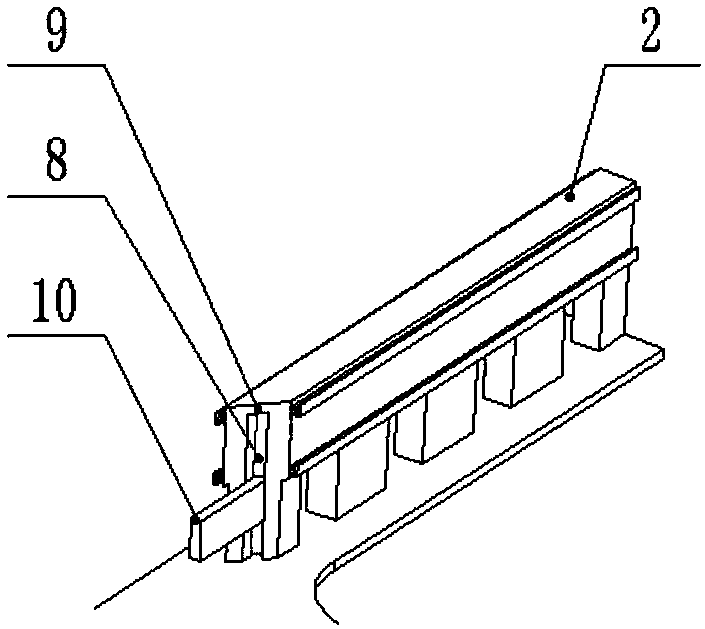

[0053] In a specific embodiment, the elevating type straddle type single track switch includes a fixed turnout beam member and an elevating turnout beam member. The fixed turnout beam components include 1# turnout beam fixed end 1, 2# turnout beam fixed end 2, and 3# turnout beam fixed end 3; the lifting turnout beam includes 1# turnout lifting beam 4 and 2# turnout lifting beam 5.

[0054] Various schemes can be implemented on the fixed end of the turnout beam and the lifting contact surface of the lifting beam of the turnout. In this embodiment, when the 1# turnout beam fixed end 1, 2# turnout beam fixed end 2 and 1# turnout lifting beam 4, 2# turnout lifting beam 5 lifting contact surfaces are inclined planes, the contact area between the vehicle and the turnout is increased, and more Conducive to high-speed vehicle crossing. At the same time, according to the vehicle limit, the length of the turnout can be shortened and the occupied space of the single track turnout can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com