Plane polishing machine

A plane polishing machine and a technology with a frame, which are applied in the directions of grinding/polishing equipment, grinding frames, grinding machine parts, etc., can solve the problem of low work efficiency, work experience and work skills, and limited use of polishing machines. range and other issues, to achieve the effect of reducing labor costs and uniform polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

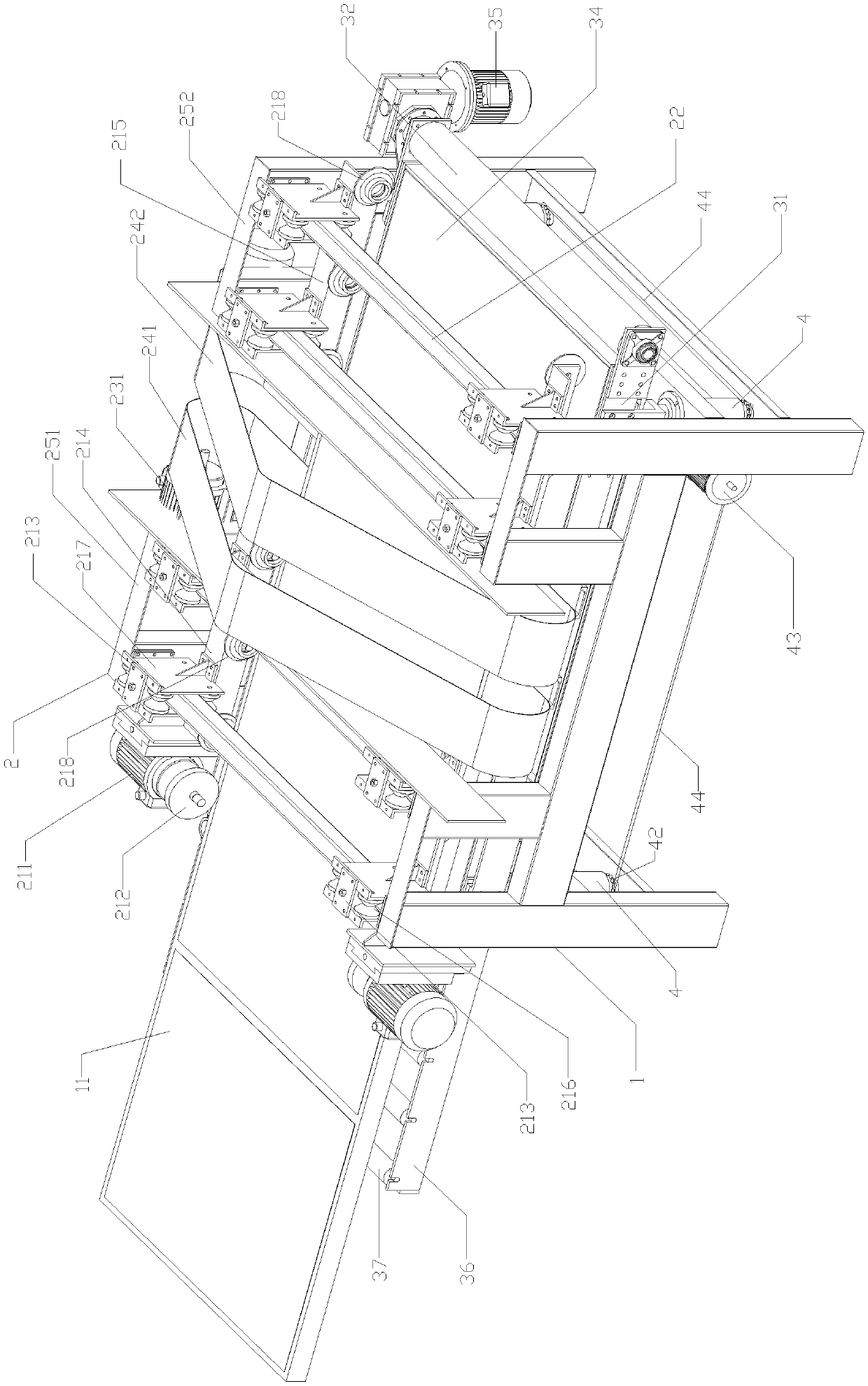

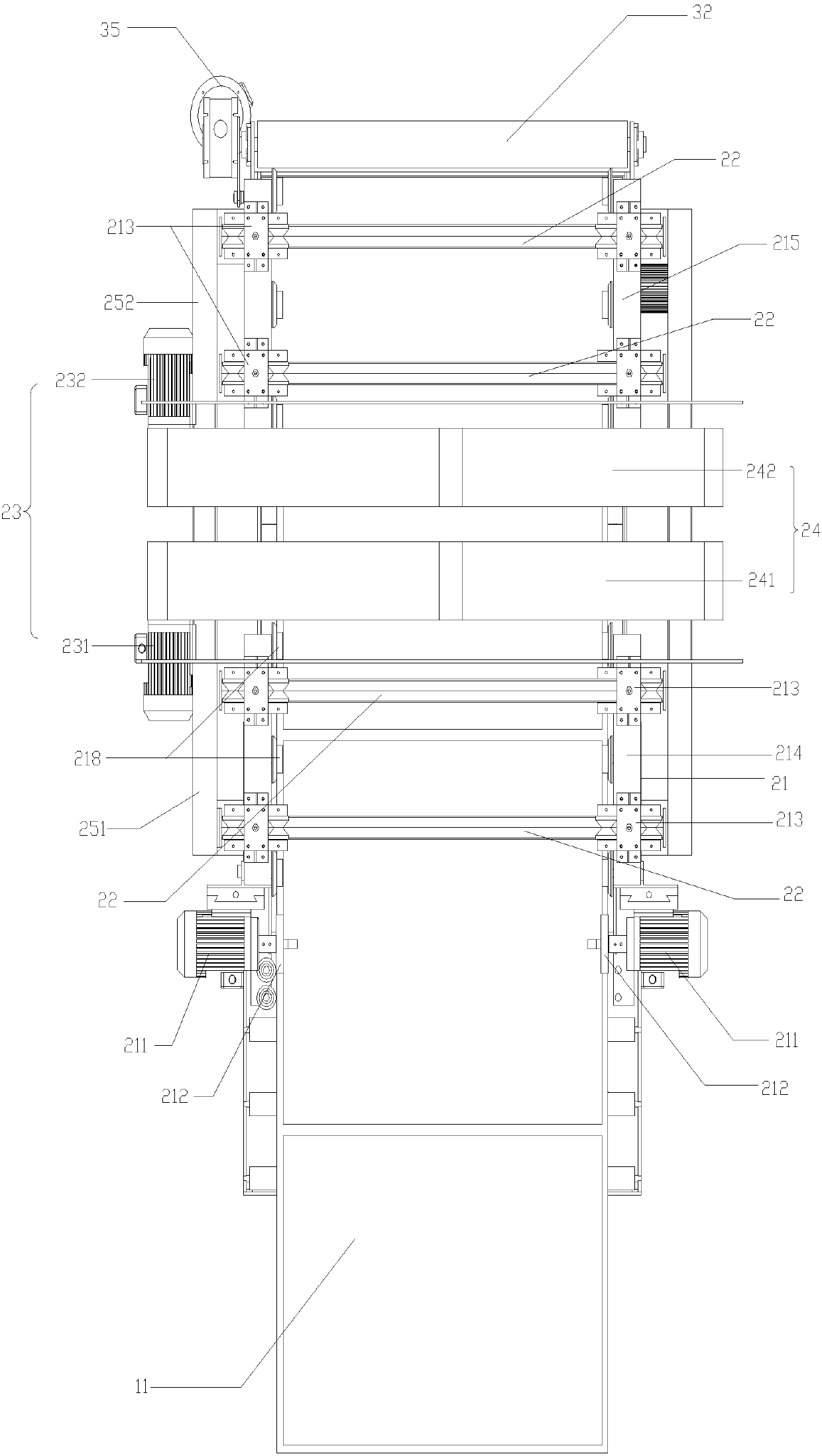

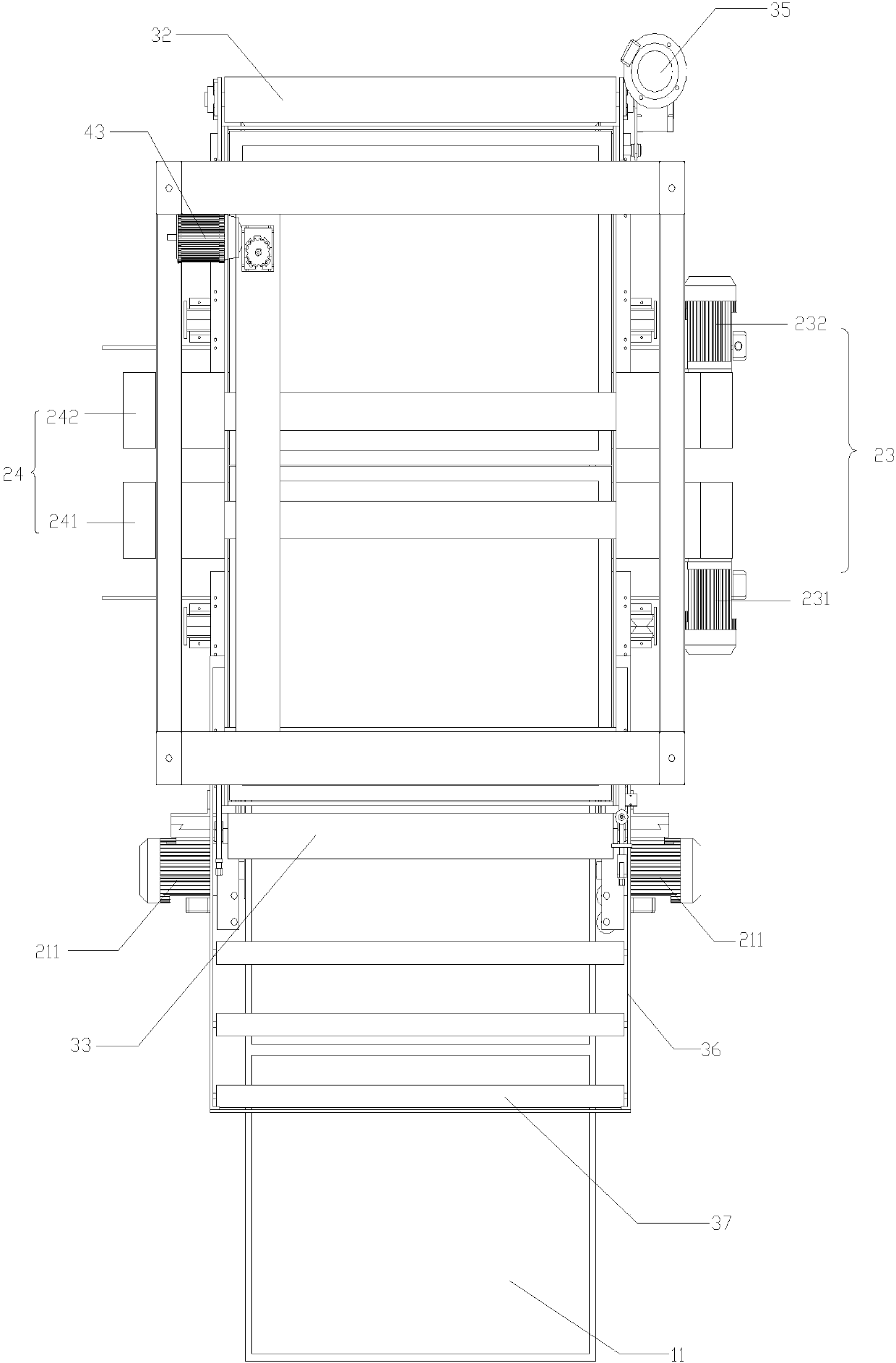

[0054] In order to fully understand the purpose, features and effects of the present invention, the following will be combined with the attached Figure 1-6 The conception, specific structure and technical effects of the present invention will be further described.

[0055] Such as Figure 1-6 Shown, a kind of surface polishing machine, it comprises: workbench 1, its both sides are all provided with frame connecting plate 2, described frame connecting plate 2 is provided with width adjusting frame 21 and is used for connecting described workbench 1 the transverse guide rails 22 of the rack connection plates 2 on both sides;

[0056] The width adjustment frame 21 is provided with a width adjustment device 213 that moves back and forth along the length direction of the transverse guide rail 22, and the width adjustment device 213 on both sides of the workbench 1 is moved to adjust the width of the workbench 1 on both sides. The distance between the width adjustment frame 21, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com