Corrosion-resistant polishing treatment process for stainless steel pipe

A technology of stainless steel pipe and processing technology, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, manufacturing tools, etc. It can solve the problems that it is difficult to meet the long-term use requirements and the nickel layer is easy to fall off, and achieve excellent polishing effect. The effect of improving high temperature mechanical properties and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A corrosion-resistant polishing treatment process for stainless steel pipes, comprising the steps of:

[0054] The first step is to select CN1515 austenitic stainless steel pipes for cold rolling treatment; cold rolling treatment is carried out in a conventional way according to the steel pipe size requirements;

[0055] The second step is to solution anneal the cold-rolled pipe at 1060°C for 15 minutes;

[0056] The third step is to process the pipe obtained in the previous step with 7% deformation by cold drawing machine for production, and then recrystallize and anneal at 1060°C for 10 minutes;

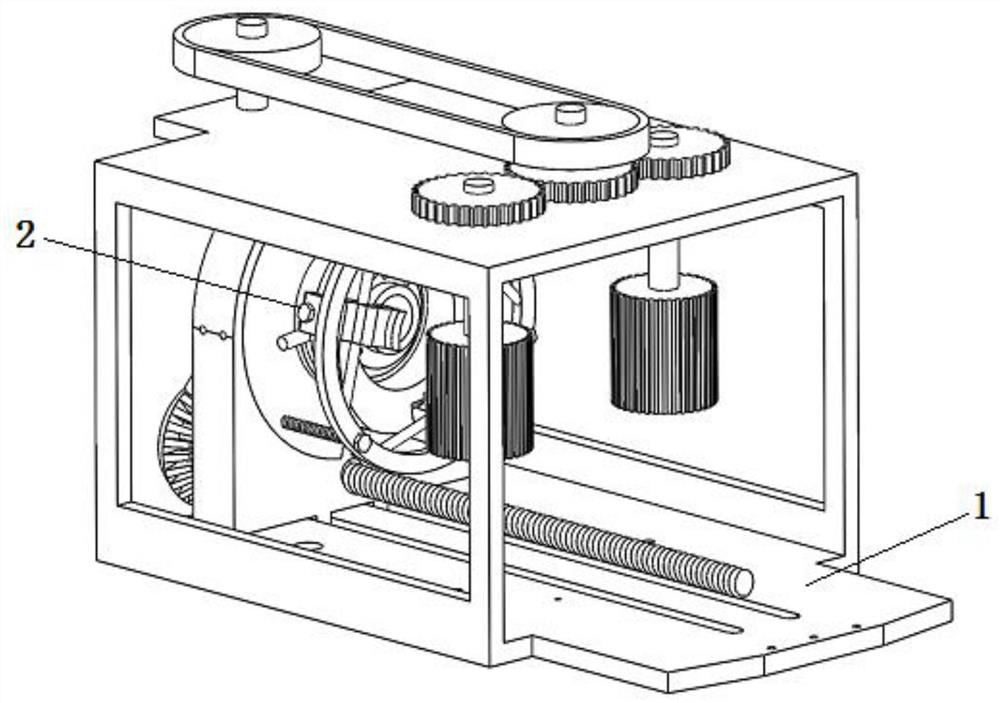

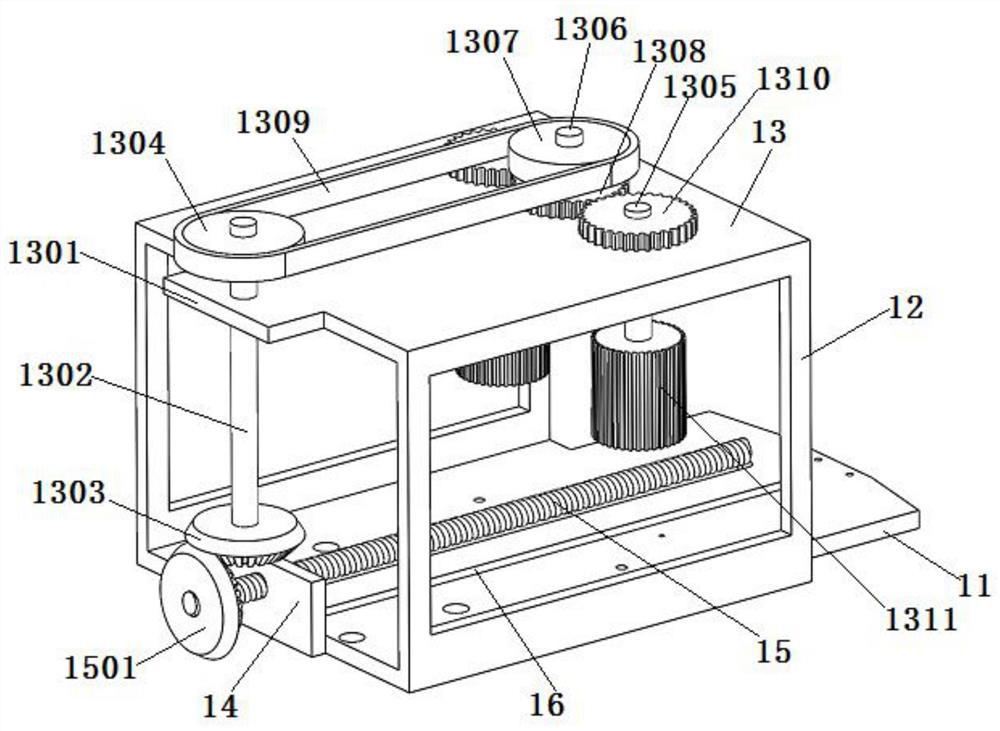

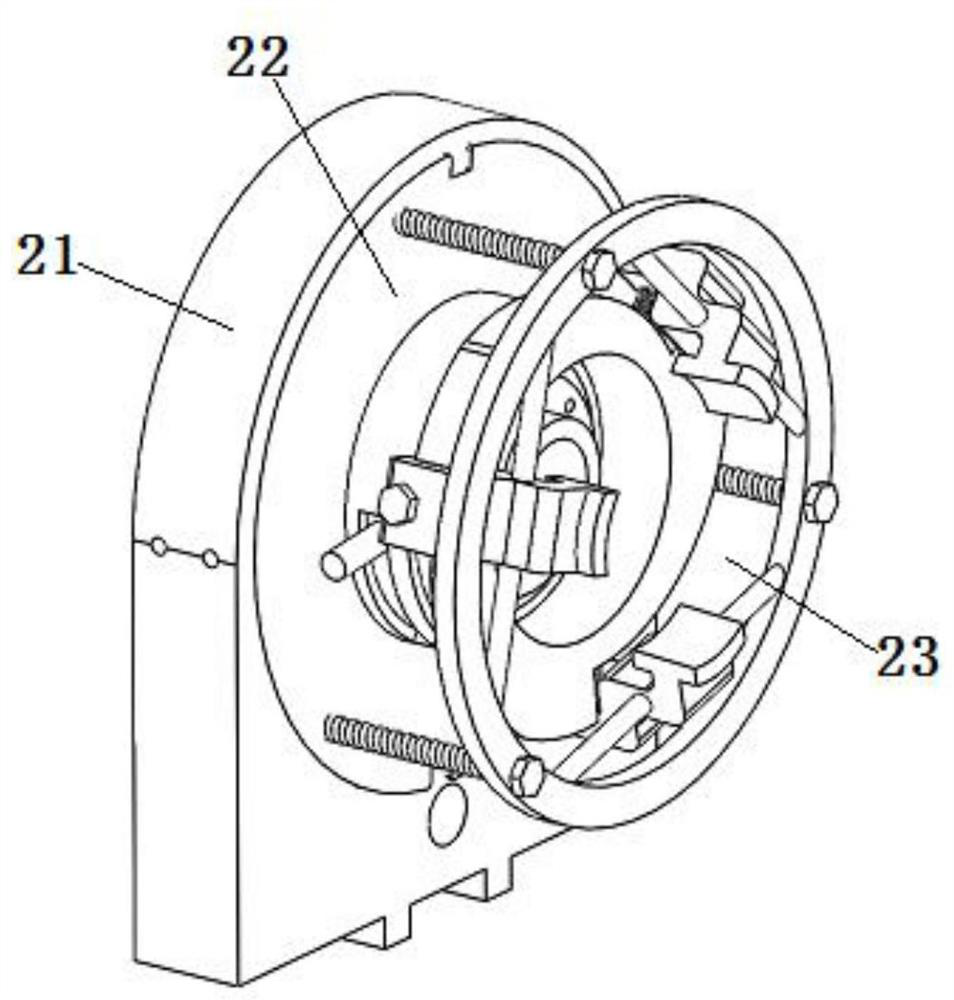

[0057] The fourth step is to place the steel pipe obtained in the previous step in the steel pipe polishing equipment. Specifically, pass the steel pipe through the positioning cylinder 2307 and contact the disc 2201, and move the rocker 2308 along the circumferential direction until three Z-shaped blocks 2303 clamps the steel pipe, turns on the first motor and the second m...

Embodiment 2

[0059] A corrosion-resistant polishing treatment process for stainless steel pipes, comprising the steps of:

[0060] The first step is to select CN1515 austenitic stainless steel pipes for cold rolling treatment; cold rolling treatment is carried out in a conventional way according to the steel pipe size requirements;

[0061] The second step is to solution anneal the cold-rolled pipe at 1060°C for 15 minutes;

[0062] The third step is to process the pipe obtained in the previous step with 7% deformation by cold drawing machine for production, and then recrystallize and anneal at 1080°C for 10 minutes;

[0063] The fourth step is to place the steel pipe obtained in the previous step in the steel pipe polishing equipment. Specifically, pass the steel pipe through the positioning cylinder 2307 and contact the disc 2201, and move the rocker 2308 along the circumferential direction until three Z-shaped blocks 2303 clamps the steel pipe, turns on the first motor and the second m...

Embodiment 3

[0065] A corrosion-resistant polishing treatment process for stainless steel pipes, comprising the steps of:

[0066] The first step is to select CN1515 austenitic stainless steel pipes for cold rolling treatment; cold rolling treatment is carried out in a conventional way according to the steel pipe size requirements;

[0067] The second step is to solution anneal the cold-rolled pipe at 1060°C for 15 minutes;

[0068] The third step is to process the pipe obtained in the previous step with 7% deformation by cold drawing machine for production, and then recrystallize and anneal at 1100°C for 10 minutes;

[0069] The fourth step is to place the steel pipe obtained in the previous step in the steel pipe polishing equipment. Specifically, pass the steel pipe through the positioning cylinder 2307 and contact the disc 2201, and move the rocker 2308 along the circumferential direction until three Z-shaped blocks 2303 clamps the steel pipe, turns on the first motor and the second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com