A kind of oxygen-free copper, preparation method and application

An oxygen-free copper and intermediate alloy technology, applied in the field of copper alloys, can solve the problems of product macro surface roughness, coarse recrystallized grains, and potential safety hazards, so as to reduce the size of grain clusters, inhibit grain growth, Effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] This example provides a kind of oxygen-free copper and preparation method thereof, and concrete steps are as follows:

[0115] (1) Weigh Cu-Zr master alloy, Cu-Sr master alloy, Cu-Ce master alloy, Cu-Yb master alloy block and Electrolytic copper plate.

[0116] (2) In the graphite crucible, place a weighed electrolytic copper plate, a uniformly mixed intermediate alloy block, a refining agent accounting for 5% of the sum of electrolytic copper and alloy mass, and a 20cm covering agent (charcoal block and graphite crucible) from bottom to top. pink).

[0117] (3) in N 2 Under +CO gas atmosphere, melt the material in step (2) with an intermediate frequency induction furnace at a melting temperature of 1200°C.

[0118] (4) Under a protective atmosphere, cast the melt with uniform composition in step (3) at 1130°C.

[0119] (5) Under a protective atmosphere, the ingot obtained in step (4) is subjected to a homogenization treatment at a treatment temperature of 600° C. f...

Embodiment 2

[0124] This example provides an oxygen-free copper and its preparation method. The difference between the specific steps and Example 1 is: in step (1), the addition amount of alloying elements is 20ppm Zr, 20ppm Sr, 40ppm Ce, and 80ppm Yb.

[0125] In this example, oxygen-free copper sample 2 was prepared.

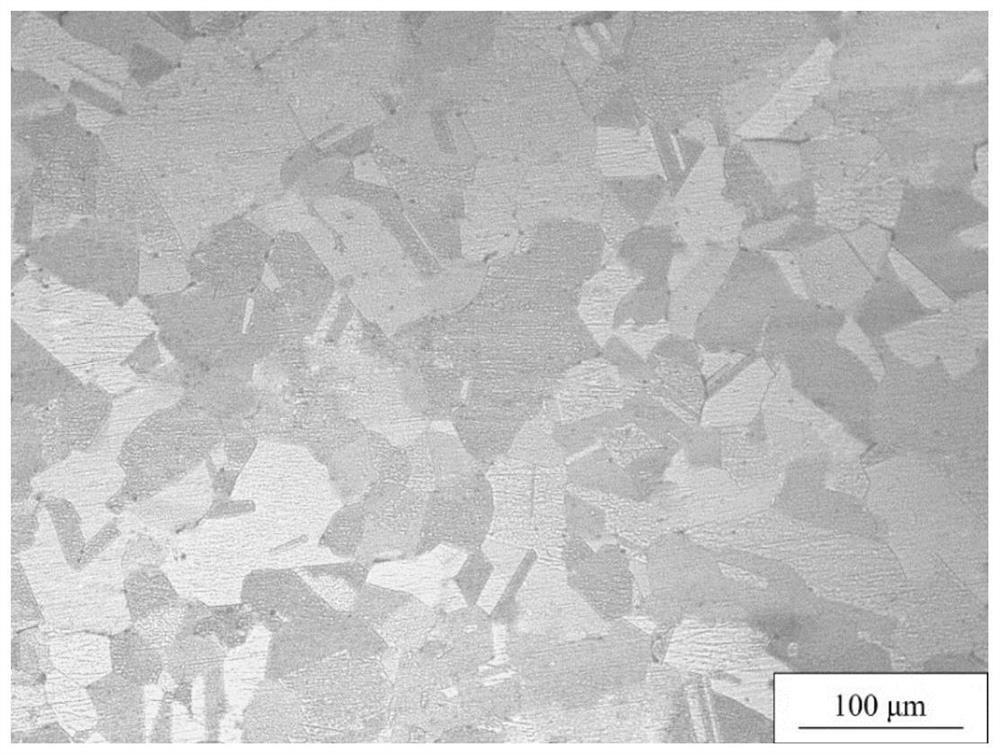

[0126] The metallographic structure of oxygen-free copper sample 2 is as follows figure 2 shown.

Embodiment 3

[0128] This example provides an oxygen-free copper and its preparation method. The difference between the specific steps and Example 1 is: in step (1), the addition amount of alloying elements is 15ppm Zr, 15ppm Sr, 15ppm Ce, and 40ppm Yb.

[0129] In this example, an oxygen-free copper sample 3 was prepared.

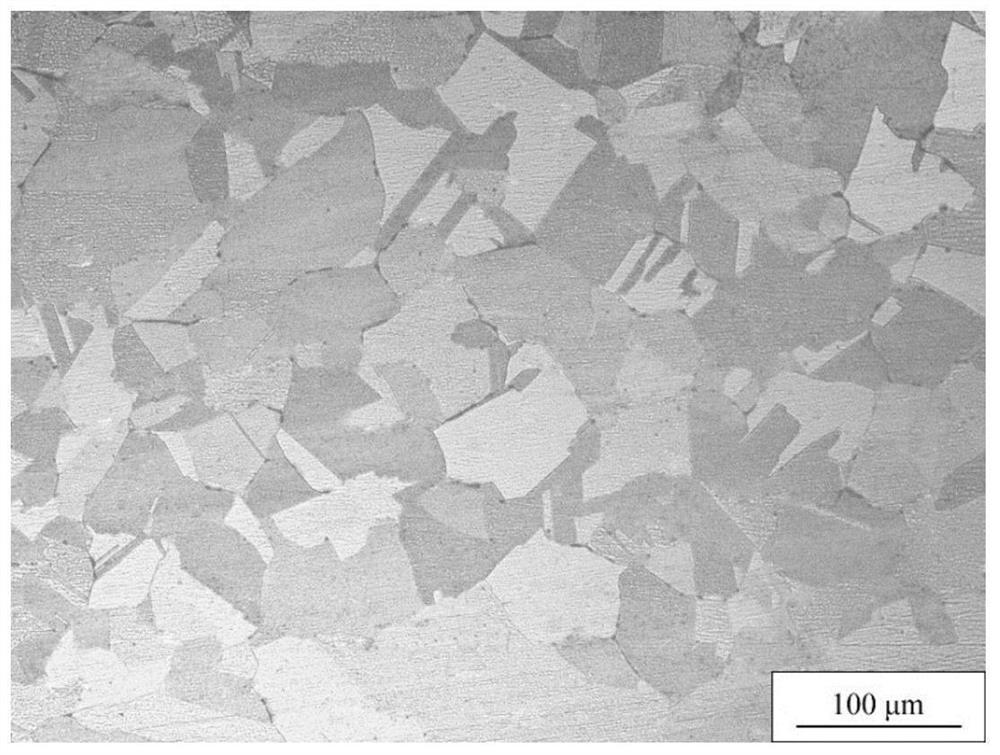

[0130] The metallographic structure of oxygen-free copper sample 3 is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com