Preparation method of plate special for hydrogen embrittlement-resistant diaphragm of high-pressure hydrogen diaphragm compressor

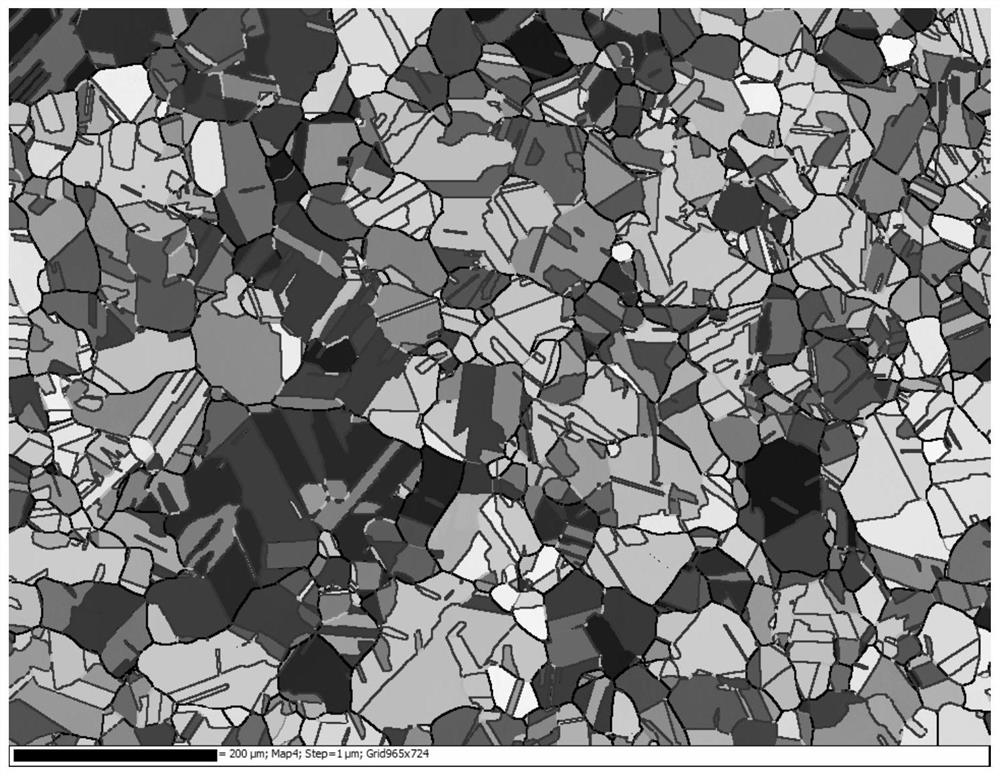

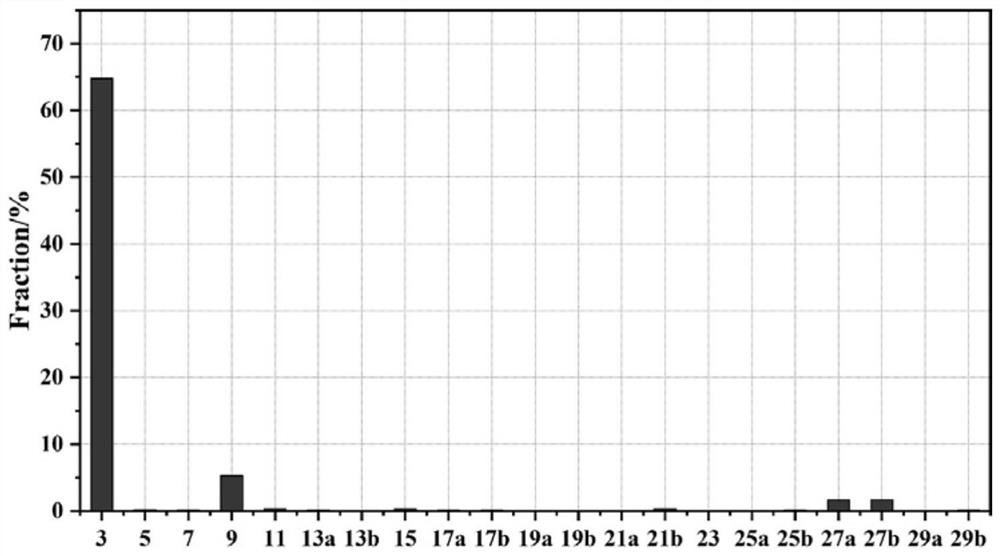

A diaphragm compressor, high-pressure hydrogen technology, used in mechanical equipment, machines/engines, liquid variable-capacity machinery, etc., can solve the problems of reduced service life, limited service life, diaphragm failure and other problems of 316L diaphragms, and achieves good performance. Excellent plasticity, excellent resistance to hydrogen embrittlement, and high proportion of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: specification is the sheet material of 1500mm * 830mm * 0.57mm

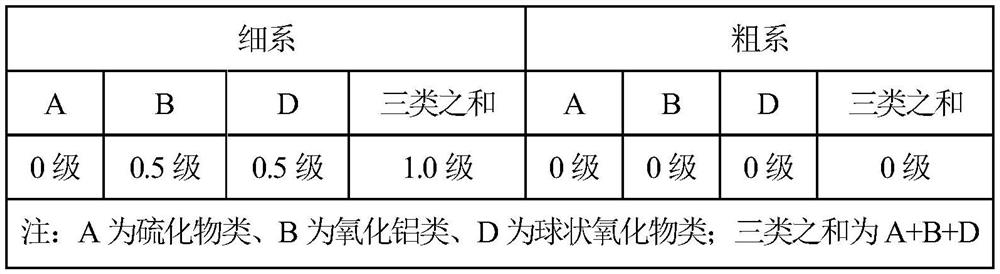

[0039]Aluminum-magnesium spinel crucibles are used to melt the alloy on a 1.0-ton vacuum induction furnace. During the melting process, a refining and a refining desulfurization treatment are performed, and then the ingot is cast; the ingot is subjected to electroslag remelting after surface grinding, and remelted The ingot is ground and then forged→hot rolling→cold / finish rolling→plate solid solution→small deformation rolling→annealing heat treatment→cut to length to prepare a special plate of 1500mm×830mm×0.57mm, and its chemical composition is shown in Table 1 , the preparation process is:

[0040] 1. With phosphorus content lower than 0.007wt.% industrial pure iron (0.006wt.% in this embodiment), electrolytic nickel, metal chromium, electrolytic manganese and chromium nitride as raw materials, put the above raw materials into the crucible before smelting, Load the calcium desulfurizer in...

Embodiment 2

[0068] Example 2: A plate with a specification of 1200mm×800mm×0.57mm

[0069] The difference from Example 1 is that the length of the prepared plate is 1200 mm and the width is 800 mm.

[0070] A CaO crucible is used to melt the alloy on a 500Kg vacuum induction furnace, using industrial pure iron with a phosphorus content of less than 0.006wt.%, electrolytic nickel, metal chromium, electrolytic manganese and chromium nitride as raw materials. During the smelting process, first refine at 1550°C for 10 minutes, then add a calcareous desulfurizer for 10 minutes of refining, use the thermal stability of the CaO crucible and the desulfurizer for decarburization and desulfurization, and cast ingots at 1510°C. Electroslag remelting was performed on the cast ingot, the specification of the remelted ingot was Φ240mm, and the chemical composition was shown in Table 6. Alloy forging is carried out after holding at 1150°C for 4 hours. The blank forging temperature is 1150°C and the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com