Program control efficient and accurate paper cutting method

A paper-cutting and accurate technology, applied in the direction of metal processing, etc., can solve the problems of wrong printing of printed products, inconsistency between printed products and cutting process, separation, etc., to achieve the effect of clear trimming, simple and practical correction mechanism, and reliable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

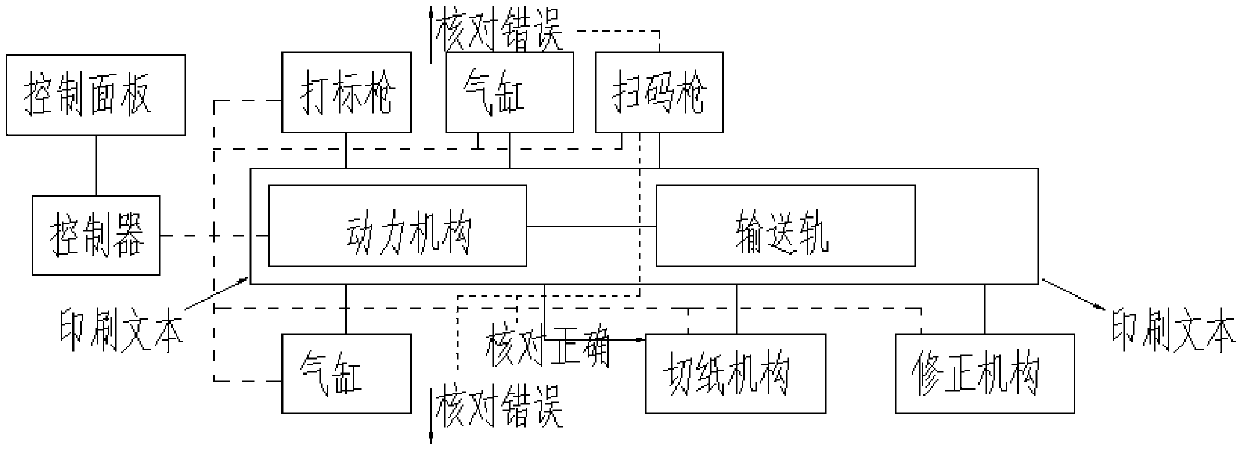

[0021] Such as figure 1 , a program-controlled efficient and accurate paper cutting method, comprising the following steps:

[0022] (1), the paper cutting method has a set of paper cutting system, the paper cutting system includes a control panel, a conveying rail, a marking gun, a code scanning gun, a paper cutting mechanism, a correction mechanism, and a cylinder, and the cylinder is an SMC cylinder , where the marking gun, code scanning gun, paper cutting mechanism, and correction mechanism are arranged along the conveyor rail from front to back and beside the conveyor rail, and several cylinders are arranged around the conveyor rail. The conveyor rail is connected to the power mechanism, the power mechanism, and the marking gun , code scanning gun, paper cutting mechanism, correction mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com