Simple and efficient auxiliary paper cutting tool

An auxiliary tooling and high-efficiency technology, which is applied in metal processing and other directions, can solve the problems of inconvenient multi-knife cutting requiring cutting oblique lines, paper cutting can only be cut in a straight line, and inconvenient paper alignment, etc., so as to improve the work efficiency of paper cutting , compact structure, good precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

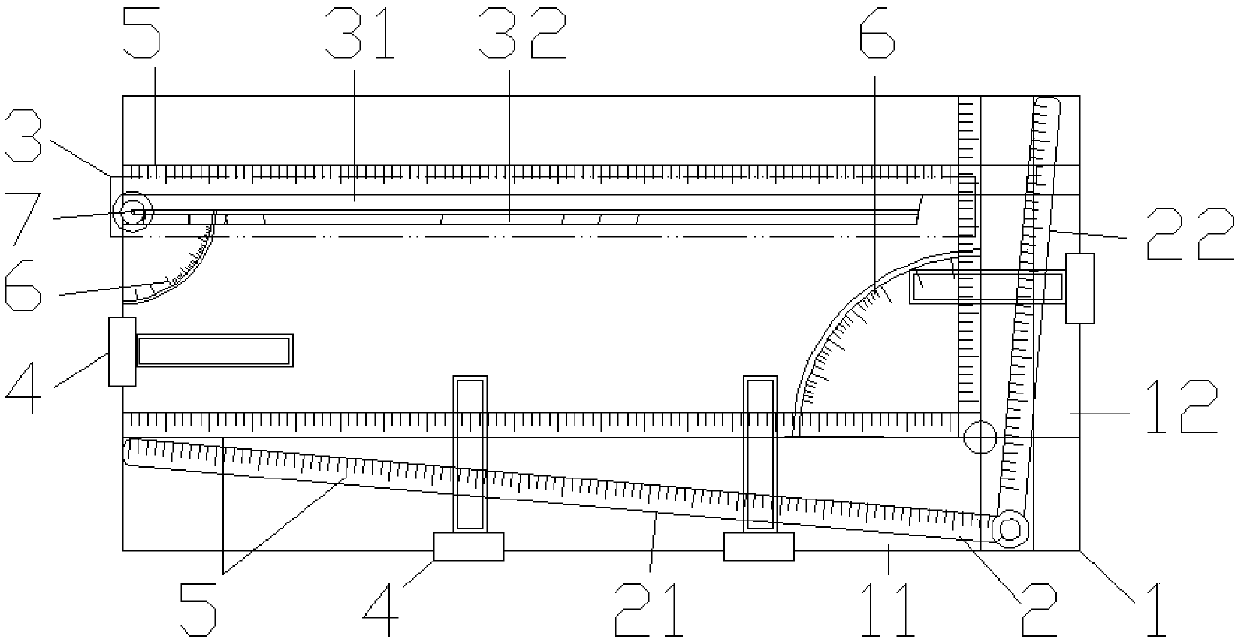

[0017] Such as figure 1 , a simple and efficient auxiliary tool for paper cutting, including a bottom operating panel 1, an upper corner plate 2, a cutter mechanism 3, and a fixing module 4. The bottom operating panel 1 is rectangular, and the bottom operating panel 1 includes mutually perpendicular transverse sections Board 11, vertical sub-board 12, described horizontal sub-board 11, vertical sub-board 12 all have scale 5, also have protractor scale 6 between horizontal sub-board 11, vertical sub-board 12, bottom operating panel 1 upper layer installs upper angle plate 2; a fixed module 4 is connected around the bottom operating panel 1; the fixed module 4 is a briquetting block or a pressure roller, and the fixed module 4 is movably connected to three of the four sides around the bottom operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com