Composite material forming machine

A composite material and forming machine technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of eccentric load of the slider and the inability of the press to meet the actual needs, so as to increase the pressing force, ensure the parallelism, and improve the response. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

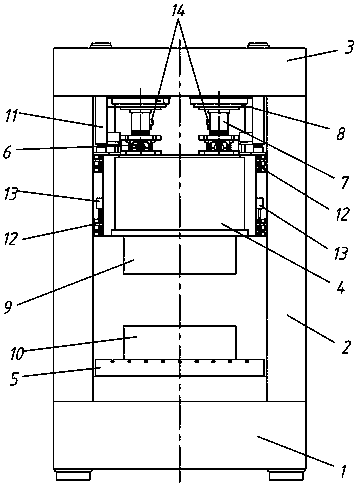

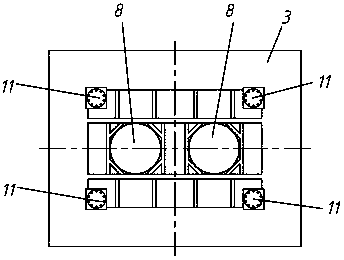

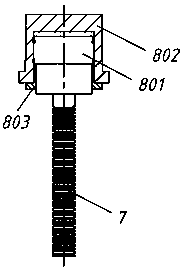

[0025] Such as figure 1 , figure 2 As shown, a composite material forming machine includes a base 1, a column 2, a top seat 3, a slider 4, a worktable 5, a brake mechanism 6, a pressurized cylinder 8, an upper mold 9, a lower mold 10, and a lifting cylinder 11 .

[0026] The frame of the composite material forming machine is formed between the top seat 3 and the base 1 through the support of the column 2 .

[0027] In the above-mentioned frame, the above-mentioned worktable 5 is installed on the base 1 , the lower mold 10 is installed on the worktable 5 , the upper mold 9 is arranged above the lower mold 10 , and the upper mold 9 is installed on the slide block 4 .

[0028] There are two above-mentioned pressurized oil cylinders 8, which are installed on the top seat 3. The two pressurized oil cylinders 8 are symmetrically arranged on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com