No-fire-return implementing external power supply device and method

A fire-free return and contact technology, applied in the field of rail transit, can solve problems such as the inability of auxiliary equipment to work, and achieve the effects of convenient installation and disassembly, simple maintenance, and simple and clear interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

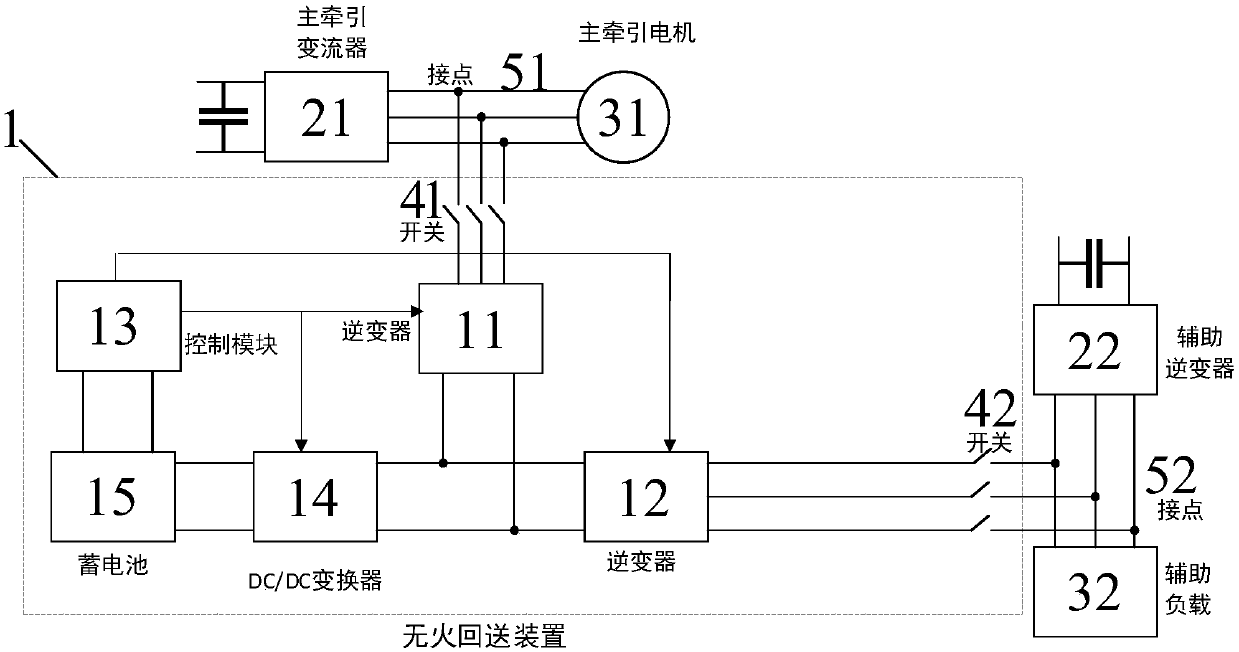

[0023] The following will combine image 3 The flameless return device of the first embodiment of the present application will be described.

[0024] The non-fire loopback device 1 of the present application is an external power supply device for realizing non-fire loopback, including: a first inverter 11, a second inverter 12, a control module 13, a DC / DC converter 14, a storage battery 15, The first switch 41 and the second switch 42 ; the first end of the first inverter 11 is connected to the first contact 51 between the main traction converter 21 and the main traction motor 31 through the first switch 41 . The second end of the first inverter 11 is connected to the first DC bus. The output end of the storage battery 15 is connected to the first end of the DC / DC converter 14 . The second end of the DC / DC converter 14 is connected to the first DC bus. The input end of the second inverter 12 is connected to the first DC bus. The output end of the second inverter 12 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com