Non-Newtonian fluid adjustable speed bump

A non-Newtonian fluid, adjustable technology, used in roads, buildings, road signs, etc., can solve the problems of severe vehicle impact, potential safety hazards, and easy aging of rubber deceleration belts. Through the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

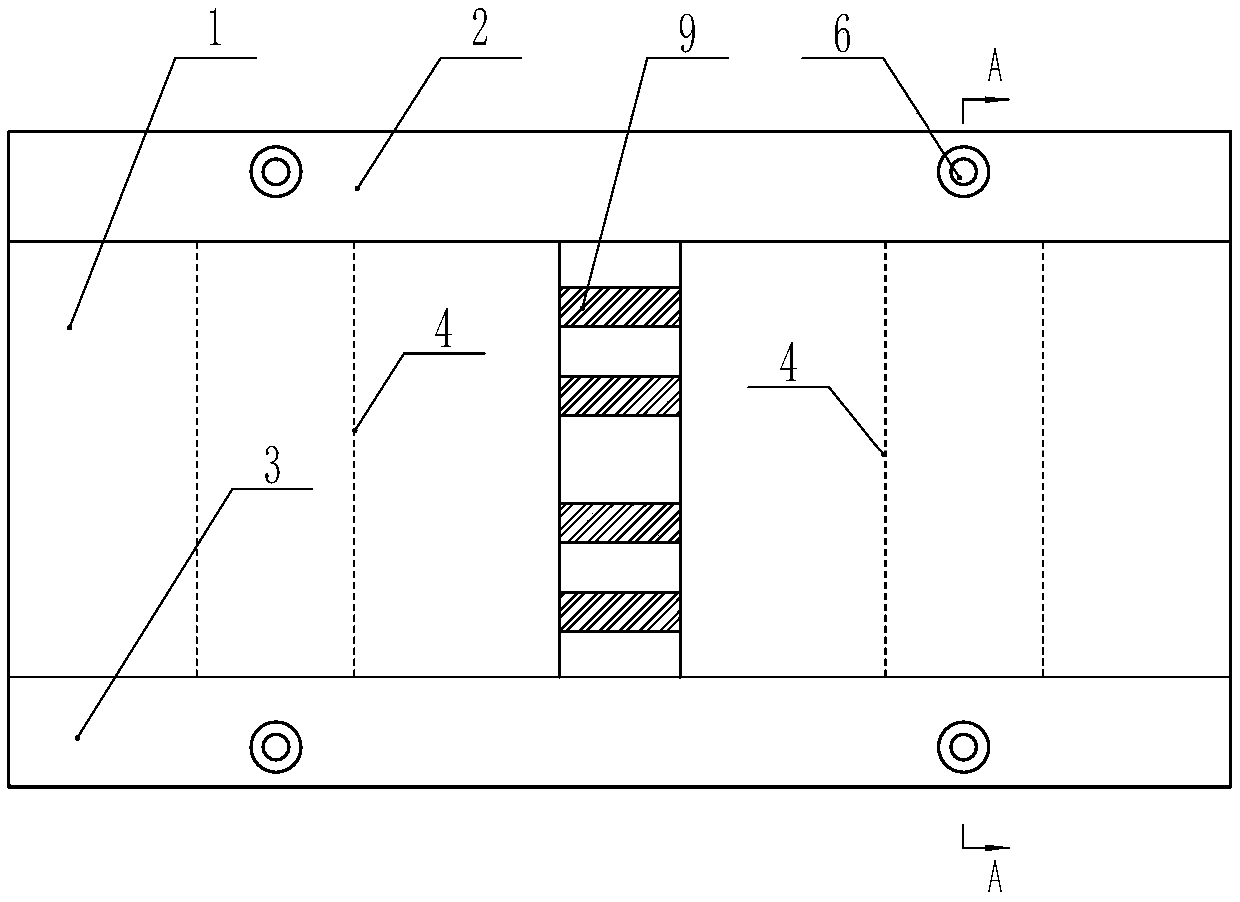

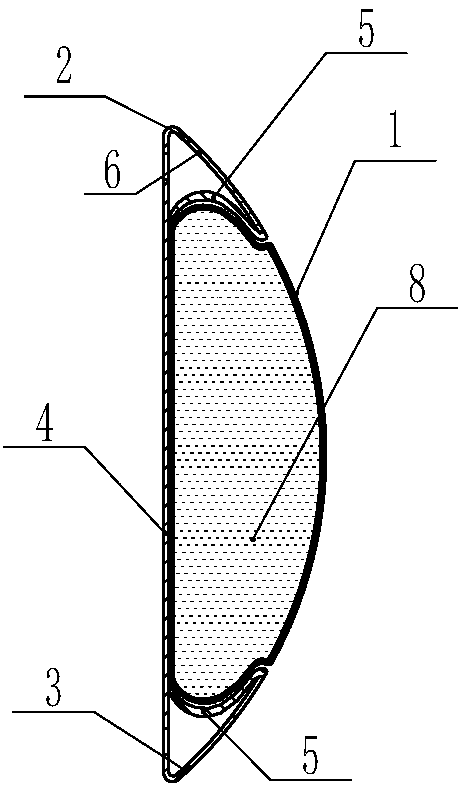

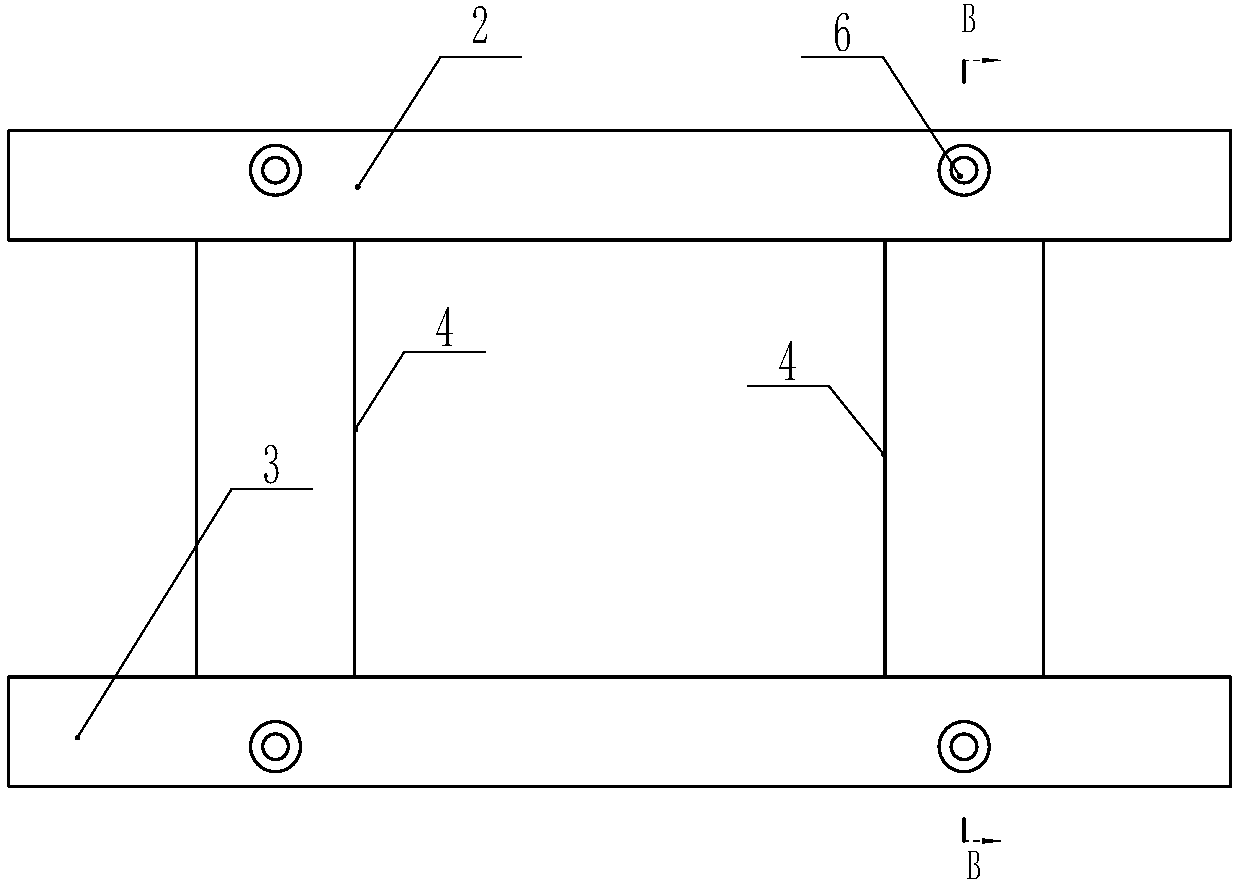

[0015] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0016] Such as Figure 1-Figure 4 As shown, the present invention provides a non-Newtonian fluid adjustable speed bump, including a rubber bag 1, a front guard 2, a rear guard 3, a bottom plate 4, and a spring support plate 5; the front guard 2 and the rear guard 3 The structures are the same, both are elongated circular arc surfaces, both are relatively parallel arranged, and are fixedly connected through the bottom plate 4; The spring support plate 5 is welded; the front guard 2 and the rear guard 3 are provided with counterbore 6; the rubber bag 1 is arranged in the cavity 7 surrounded by the spring support plate 5 and the bottom plate 4, and the rubber bag 1 Filled with non-Newtonian fluid 8, the rubber bag 1 is glued to the bottom plate 4 of the guard plate.

[0017] Further, both the front guard 2 and the rear guard 3 are welded in alignment with the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com