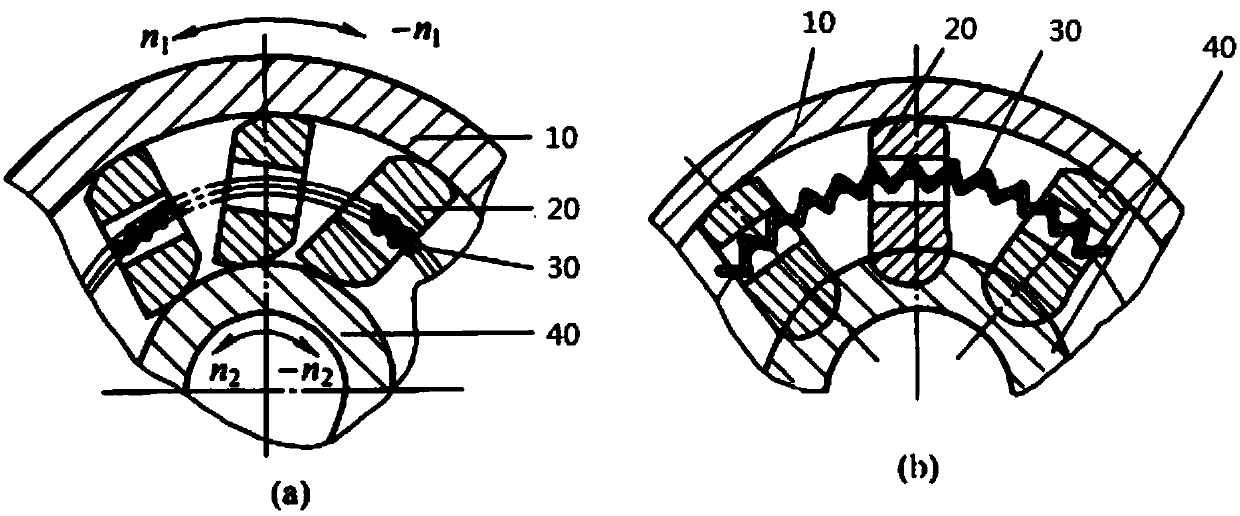

Six-column roller overrunning clutch

An overrunning clutch and roller technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of accelerating wedge and raceway wear, increasing company losses, small locking depth, etc., to delay the wedge failure. time, reducing the chance of whistling, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

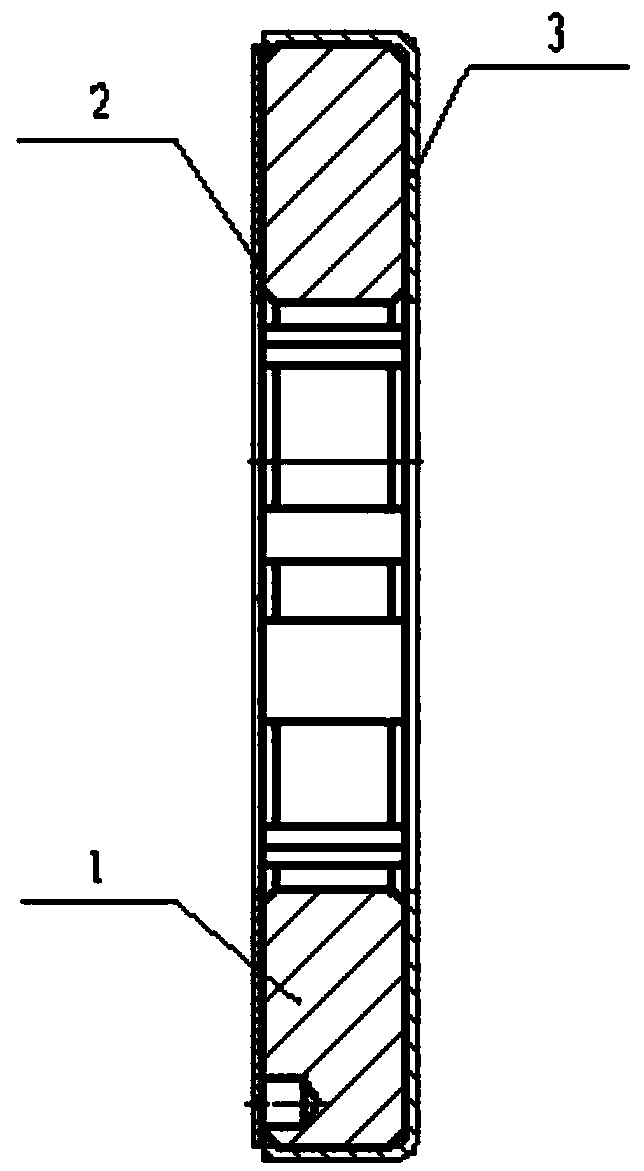

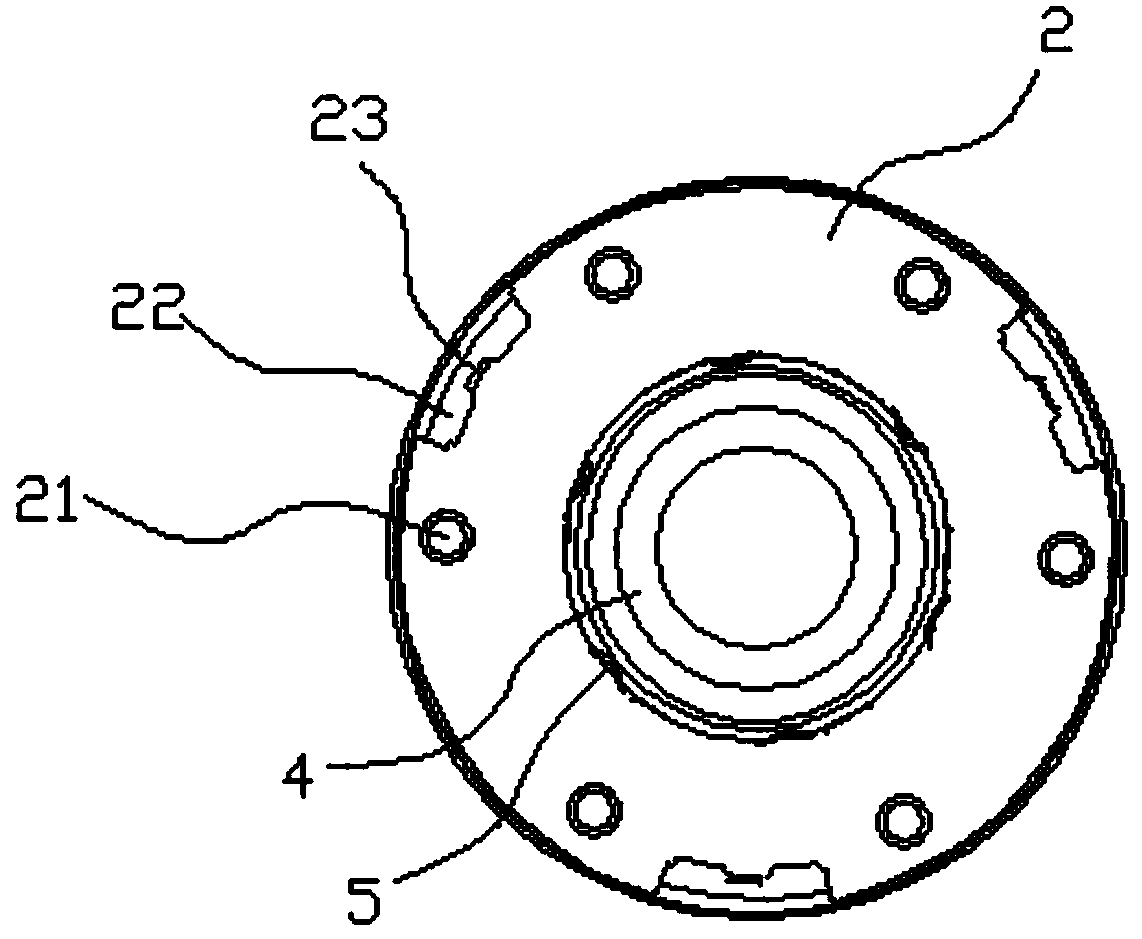

[0031] See attached Figure 2-6 , a six-column roller overrunning clutch, including a cover 3, a body 1 and a gasket 2, wherein the cover 3 is provided with a circular groove, and the bottom of the circular groove is provided with a central hole; the body 1 is in the form of a ring shape, installed in a circular groove; there are six gaps 12 in the body 1 as raceways, and rollers 5 and flat springs 6 are installed in each raceway; in the circumferential direction, rollers 5 and flat springs 6 are mutually Alternate, so that the rollers 5 move in the same direction under the action of the flat spring 6 and centrifugal force; the gasket 2 is circular, the outer cover 3, the body 1 and the gasket 2 are connected as a whole, and the gasket 2 covers the body 1 Live to prevent roller 5 and flat spring 6 from coming off.

[0032] In this embodiment, the clutch also includes a protective cover 4, which is installed in the body 1 to fasten the roller 5 and the flat spring 6 to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com