Building block lap joint structure

A technology of connecting structures and building blocks, which is applied in the field of toys, can solve problems such as insufficient connection, poor playability, and easy collapse of building blocks, and achieve the effect of simple structure, strong connection firmness, and high playability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

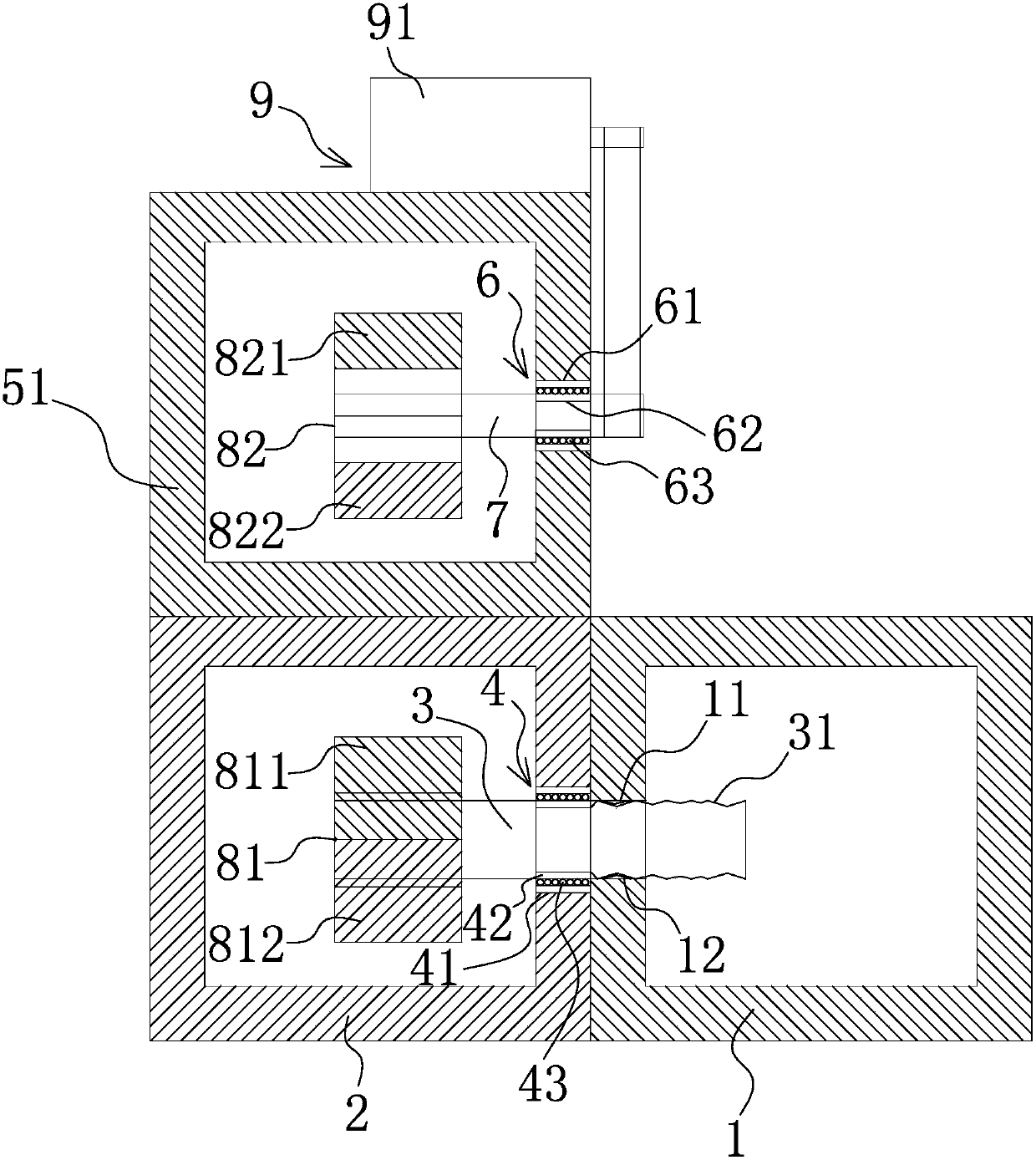

[0022] Such as figure 1 As shown, the building block overlapping structure includes a connecting column 3 arranged on a polyhedron-shaped adapter block 2 with an inner cavity through a first rotating installation structure 4, and the connecting column 3 penetrates through the inner cavity and the At least one end of the connecting column 3 extends to the outside of the adapter block 2, and at least one side of the adapter block 2 is provided with a polyhedron-shaped building block 1, and the building block 1 has a structure for inserting the end of the connecting column 3 The connecting hole 11 has an internal thread 12 in the connecting hole 11, and the end of the connecting column 3 extending to the outside of the adapter block 2 has an external thread 31 engaged with the internal thread 12. The connecting column 3 One end located in the inner cavity is provided with a first magnetic body 81 having a first S pole 811 and a first N pole 812, and the upper or lower end of the ...

Embodiment 2

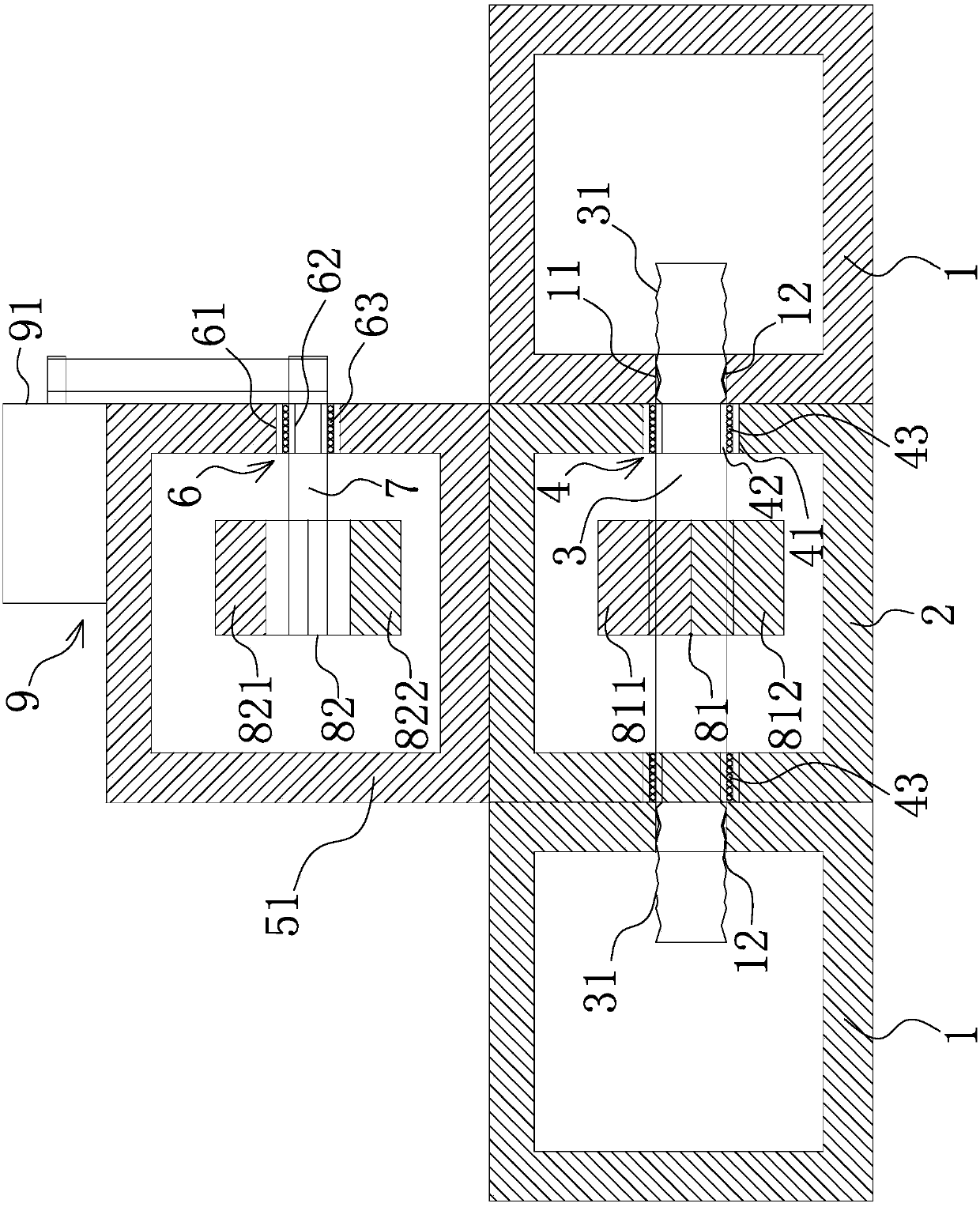

[0029] Such as figure 2 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference lies in that the two ends of the connecting column 3 in this embodiment respectively extend to the outside of the adapter block 2, and the first magnetic body 81 is ring-shaped, the first magnetic body 81 is sleeved in the middle of the connecting column 3 and the first magnetic body 81 and the connecting column 3 are coaxially arranged, and the first S pole 811 and the first N pole 812 are both in the form of The first magnetic body 81 described above is formed by splicing the two in an arc-shaped block in a radial direction.

[0030]That is to say, both ends of the connecting column 3 extending to the outside of the adapter block 2 have external threads 31 , and the thread directions of the two sections of external threads 31 are opposite. Here, the connecting column 3 in the adapter block 2 is used to overlap two build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com