Packaging dust removal method for feed inlet

A technology of blanking and dust removal hood, which is applied in the direction of dust removal, separation methods, chemical instruments and methods, etc., and can solve the problems of poor dust collection effect and easy generation of dust at the feeding port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

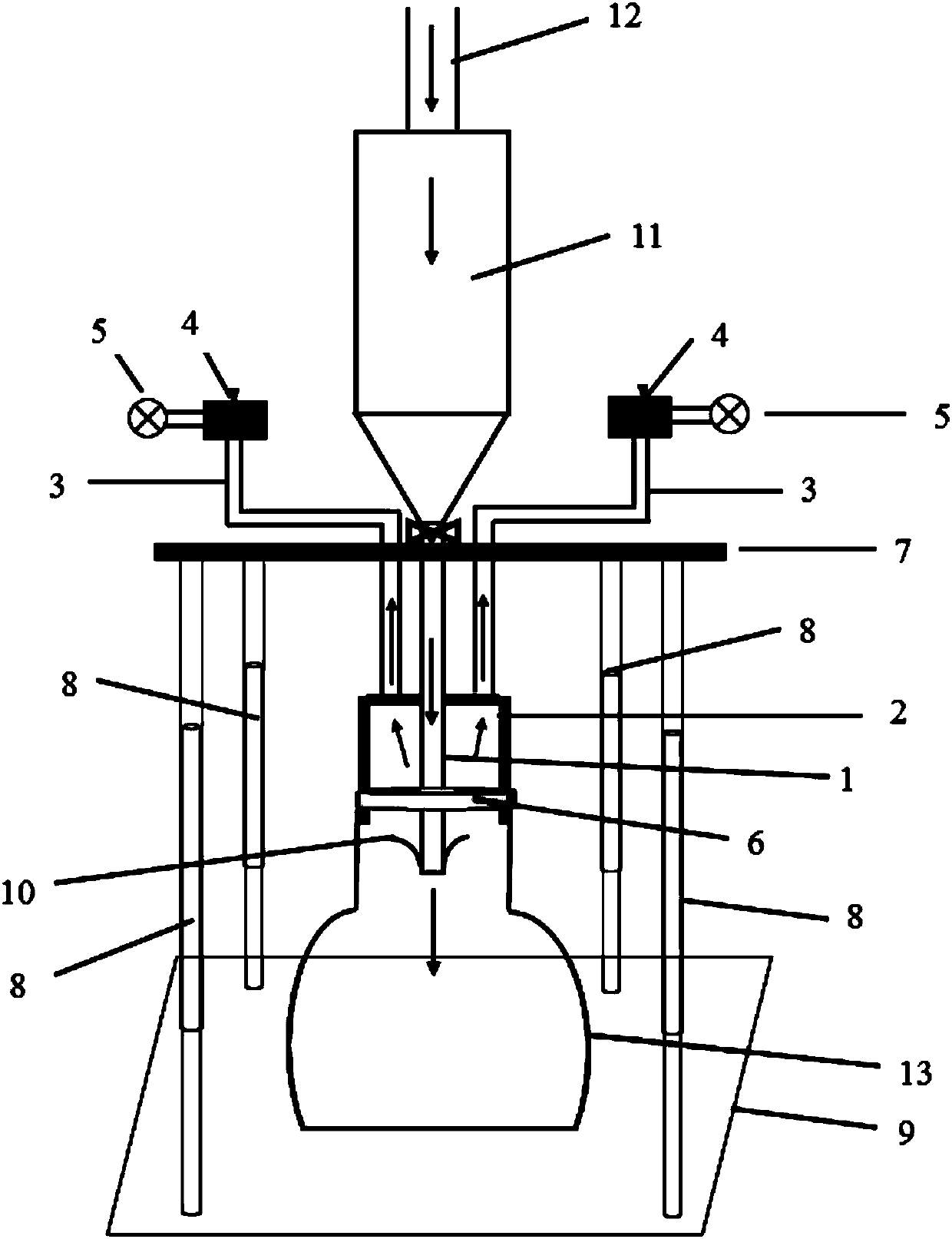

[0011] A kind of packing dust removal method of feeding port, such as figure 1 As shown, the entire packaging dust removal device consists of a silo discharge pipe, a dust removal cover, a dust removal air duct, a bag filter, a fan, a bag clamping device, an automatic lifting device, and a baffle. The bag clamping device is a pair of semicircular hoops, and the packaging bag is seamlessly attached to the outer wall of the dust removal cover through the bag clamping device. The dust removal cover is fixedly sleeved on the feeding pipe of the feed bin, and the lower edge of the dust removal cover is higher than the lower edge of the feeding pipe mouth by 40cm, and the lower edge of the feeding pipe mouth has a semi-arc baffle. Dust removal air ducts are installed on both sides of the dust removal hood, the end of the dust removal air duct is connected to the bag filter, and the fan is connected to the rear of the dust collector. The feeding tube is equipped with a horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com