Method for preparing novel engine dust cover plate

A technology for an engine and a dust cover, which is applied to the field of preparation of an engine dust cover plate, can solve the problems affecting the normal operation of the engine, the engine is easily burnt out, and the heat dissipation of the engine is not good, and achieves the benefits of air circulation and a simple structure. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

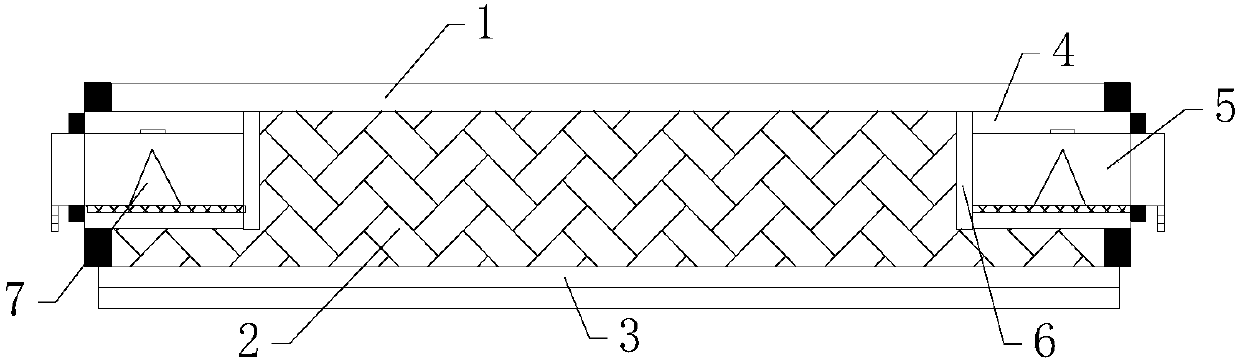

[0023] like figure 1 Said, a kind of preparation method of novel engine dust cover plate, comprises main cover plate 1 and side cover plate 5, and described main cover plate 1 comprises soundproof chamber 2 and cavity 4, and described main cover plate 1 A soundproof chamber 2 is provided in the middle, and cavities 4 are provided at both ends of the soundproof chamber 2;

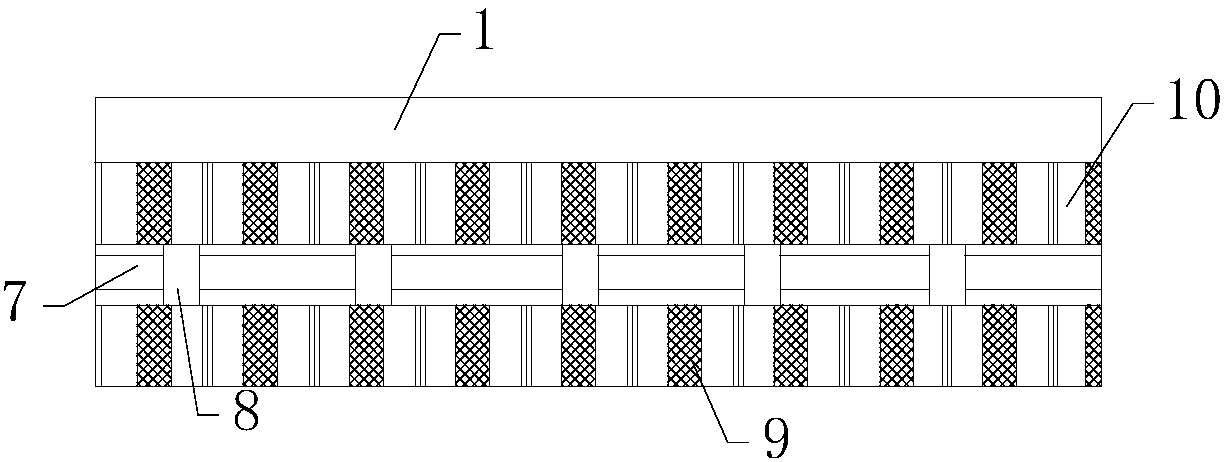

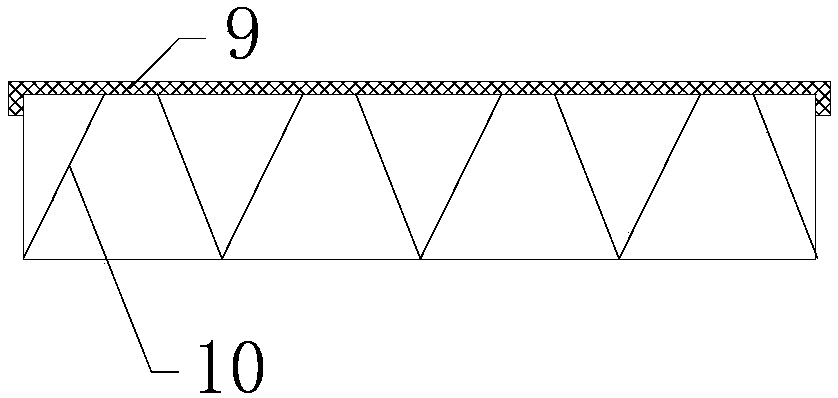

[0024] The side cover plate 5 is installed in the cavity 4, and the end of the side cover plate 5 connected to the cavity 4 is provided with a limit stop 6, and the side cover plate 5 is formed by connecting several sub-plates. The sub-boards mentioned above are connected by connecting pieces 8.

[0025] The two ends of the main cover 1 are connected with the side cover 5 with sealing rubber pads, the lower end of the main cover 1 is provided with a mounting edge 3, and the lower end of the mounting edge 3 is provided with a connecting groove.

[0026] Further, the side cover plate 5 is provided with a num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com