Full-automatic mixing and paving apparatus for concrete sand and gravel

A laying device and fully automatic technology, applied in clay preparation devices, cement mixing devices, roads, etc., can solve problems such as low work efficiency and complexity, and achieve the effect of saving labor and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

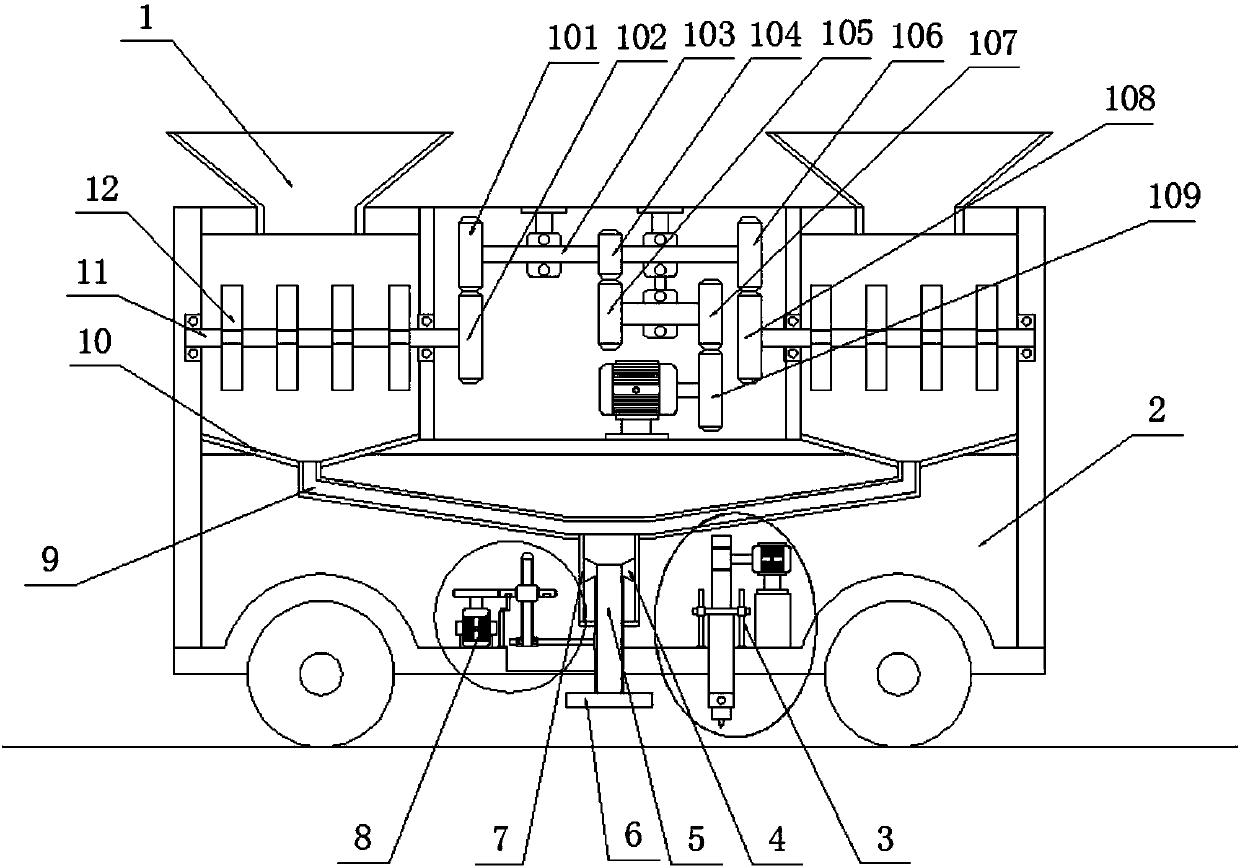

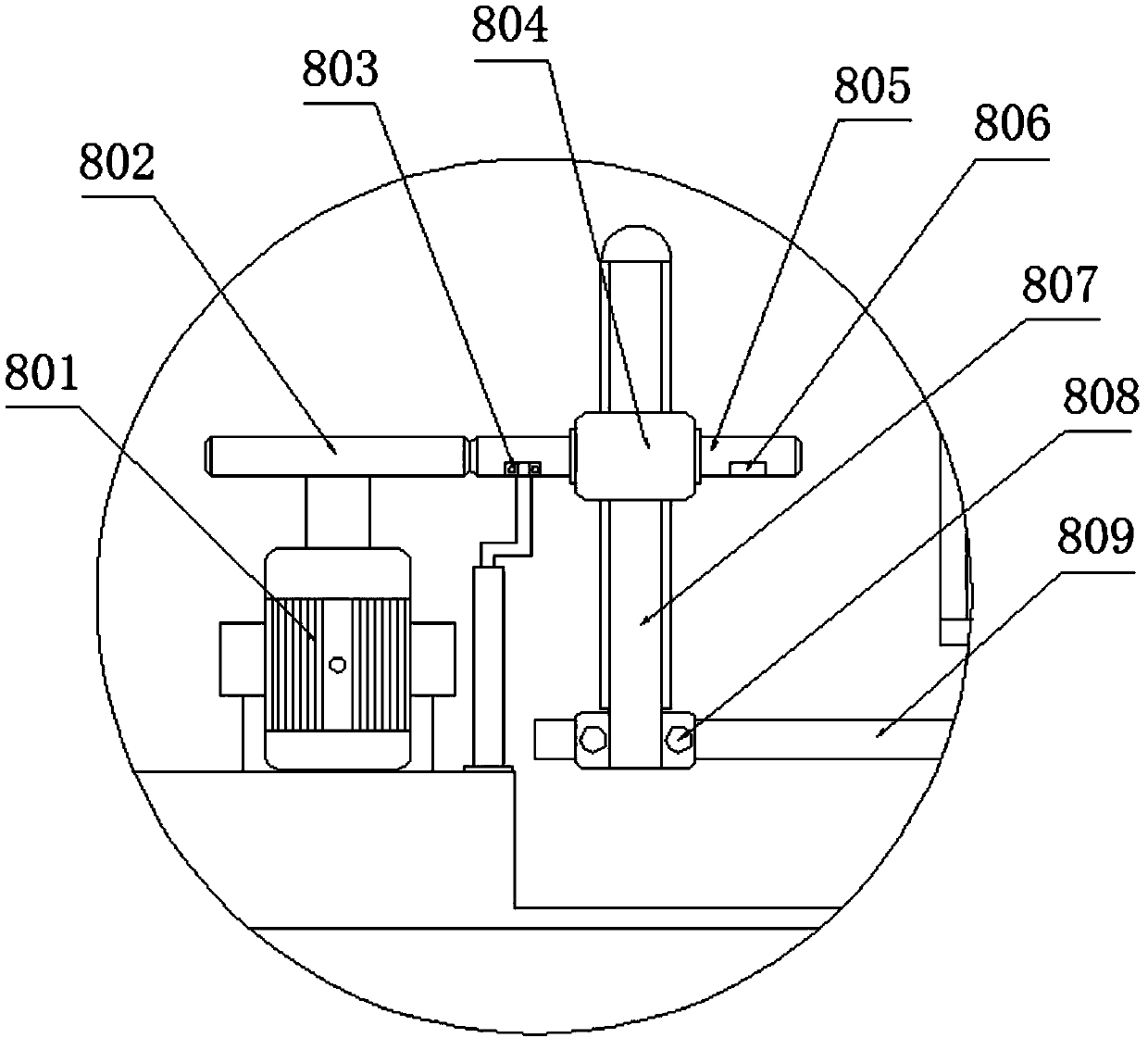

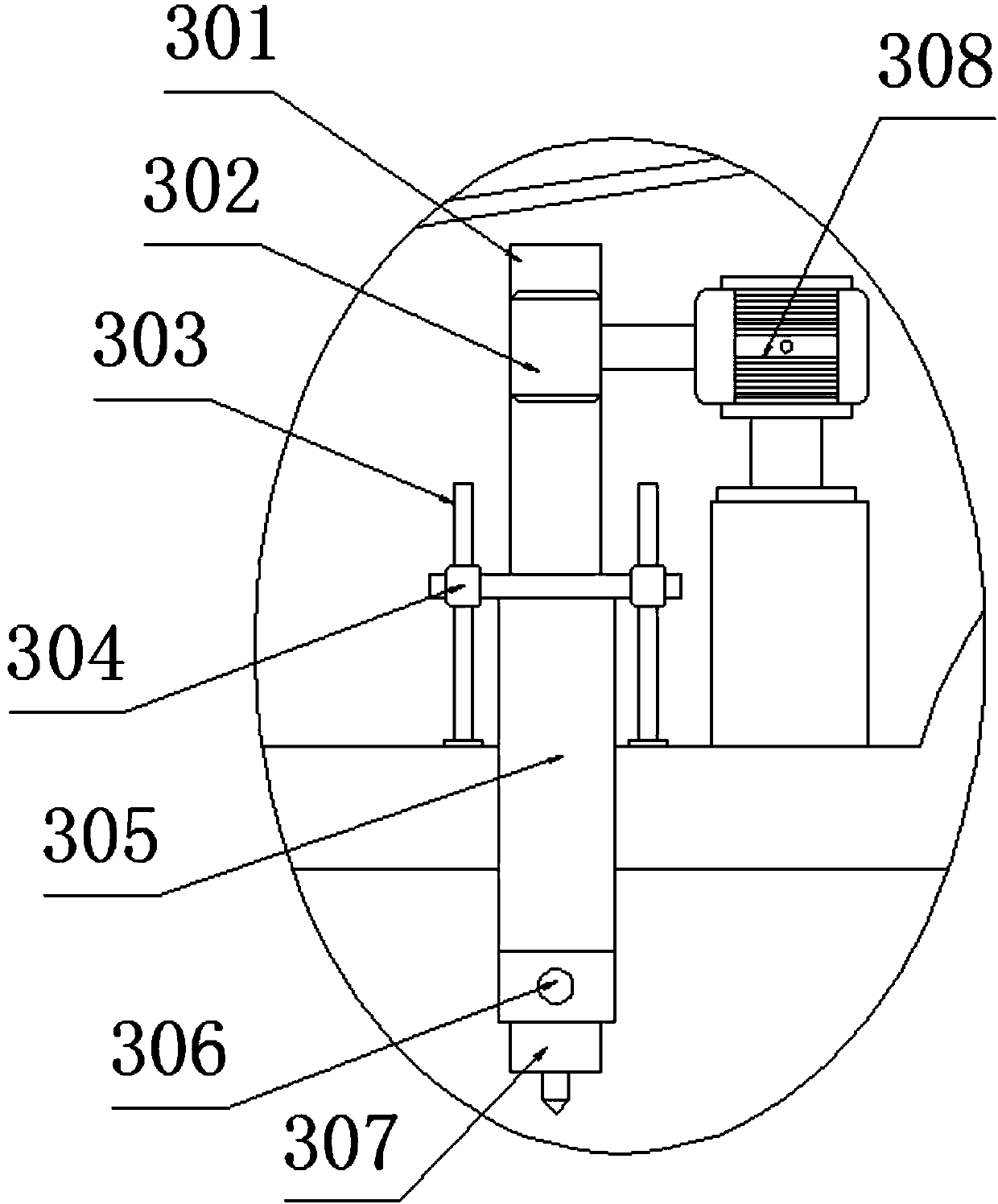

[0018] The specific implementation is as follows: in the process of use, concrete and mortar are added from the hopper 1 at the same time, and enter the inside of the mixing chamber in the stirring device. At this time, the power device is turned on, and the gear H109 is driven by the motor D in the power device. , gear H109 drives gear F107, gear F107 drives gear D105, and gear D105 drives gear C104. Since gear A101, gear C104 and gear E106 are all located on the transmission shaft A103, gear A101 and gear E106 will rotate together, and gear A101 drives and The gear B102 connected to one stirring device and the gear E106 drive the gear G108 connected to another stirring device. At this time, the two stirring devices are in a synchronous rotation state, and the two stirring devices are stirring the concrete and mortar at the same time. The mixture with concrete enters the piston cavity 7 through the connecting pipe 9, and then enters the piston tube 5, and finally the mixture i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com