Cohesive soil cleaning device for cutter

A cleaning device and cohesive soil technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problem of cohesive soil clogging the reamer, avoid the clogging of the reamer head, avoid cohesive soil unity, and ensure construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

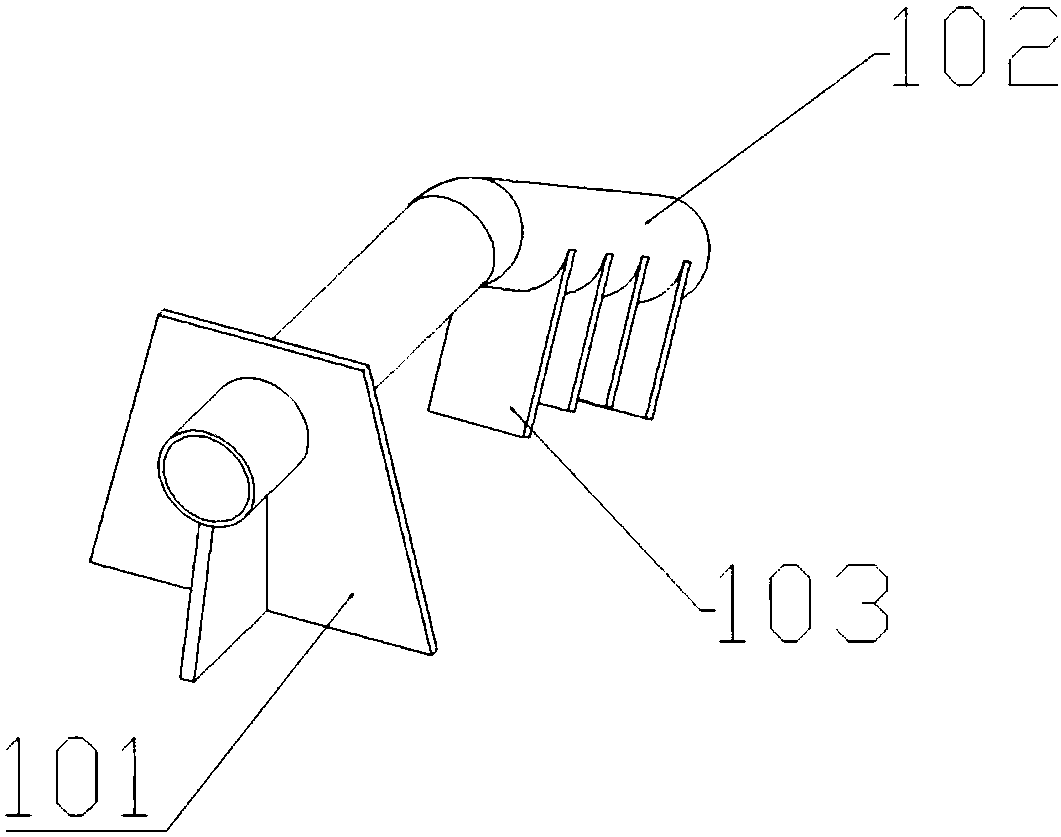

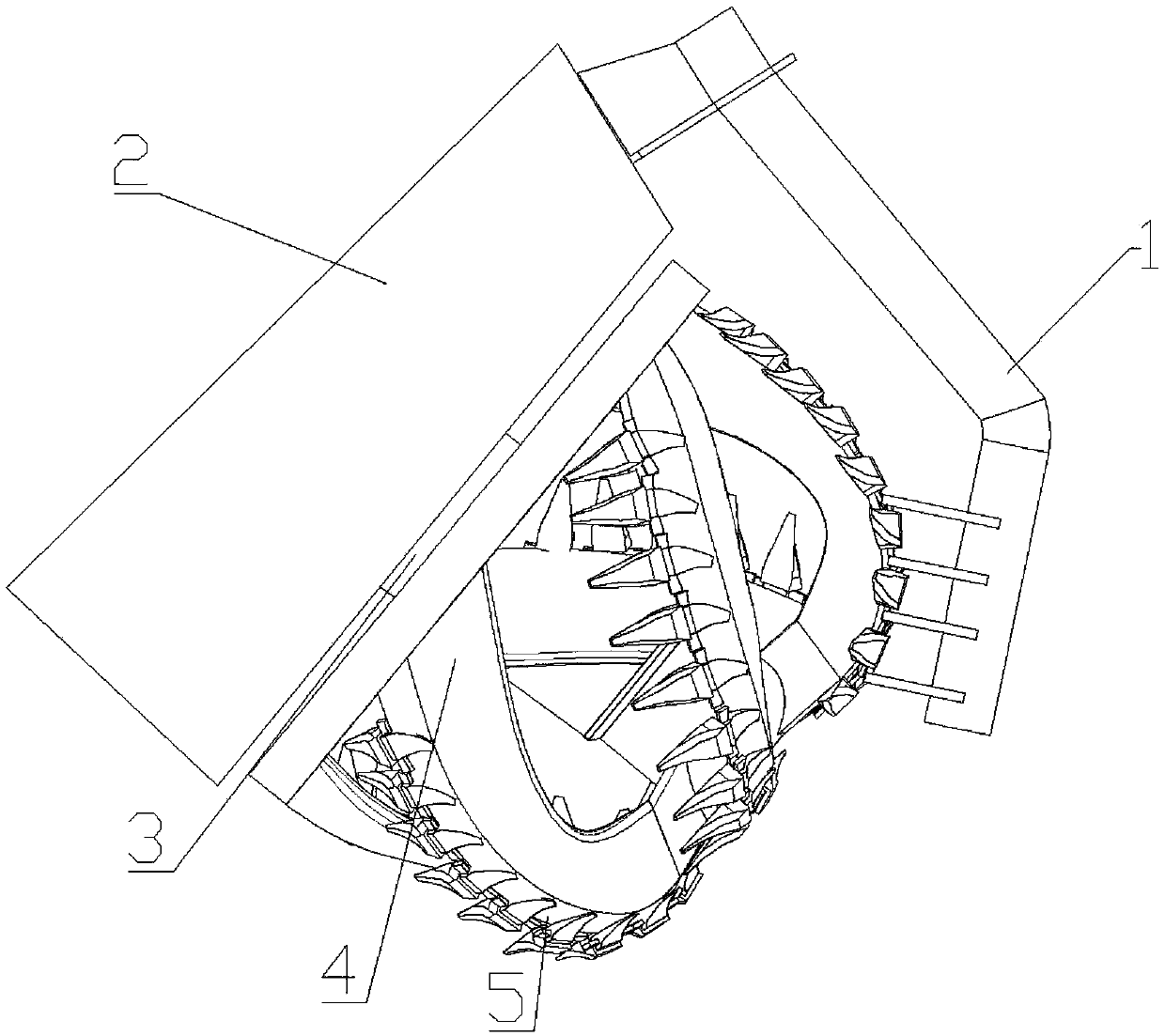

[0022] Such as figure 1 with figure 2 As shown, the sticky soil cleaning device 1 of the present invention comprises a base 101, a blade holder 102 welded on the base 101, at least one soil scraping blade 103 welded on the blade holder 102, and the soil scraping blade 103 It is arranged between two reamer teeth 5 on the reamer head 4 , the thickness and length of the soil scraping blade 103 are matched with the reamer teeth 5 , and the base 101 is welded on the bridge frame 2 . The reamer head 4 is installed on the bridge frame 2 through the reamer shaft 3 .

[0023] The working principle of the present invention is as follows: the reamer head 4 is installed on the bridge frame 2 by the reamer shaft 3 and rotates to break the soil. The cohesive soil between the reamer teeth 5 is scraped off, thereby avoiding the cohesion of the cohesive soil between the reamer teeth 5 .

[0024] As a preferred embodiment, the base 101 is composed of a bottom plate and reinforcing ribs, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com