Coal Gasification Wastewater Treatment Plant

A technology of coal gasification wastewater and treatment equipment, which is applied in water/sludge/sewage treatment, aerobic process treatment, sustainable biological treatment, etc., and can solve the problems of large footprint and low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

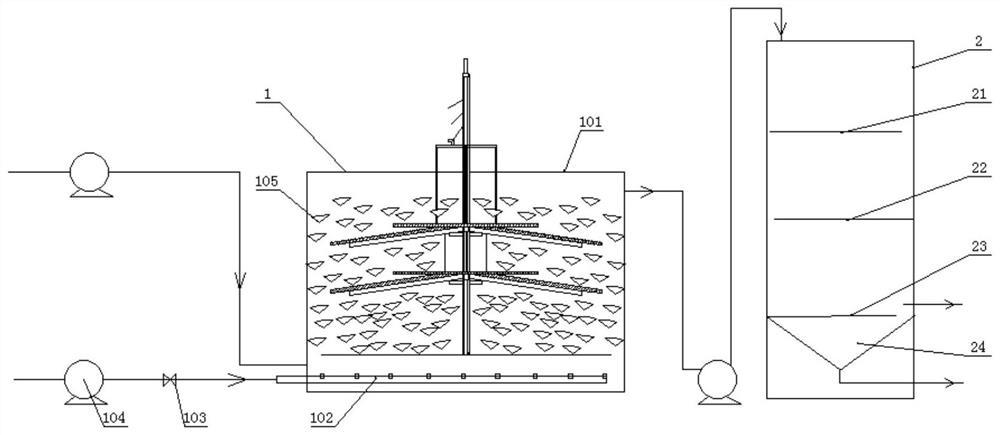

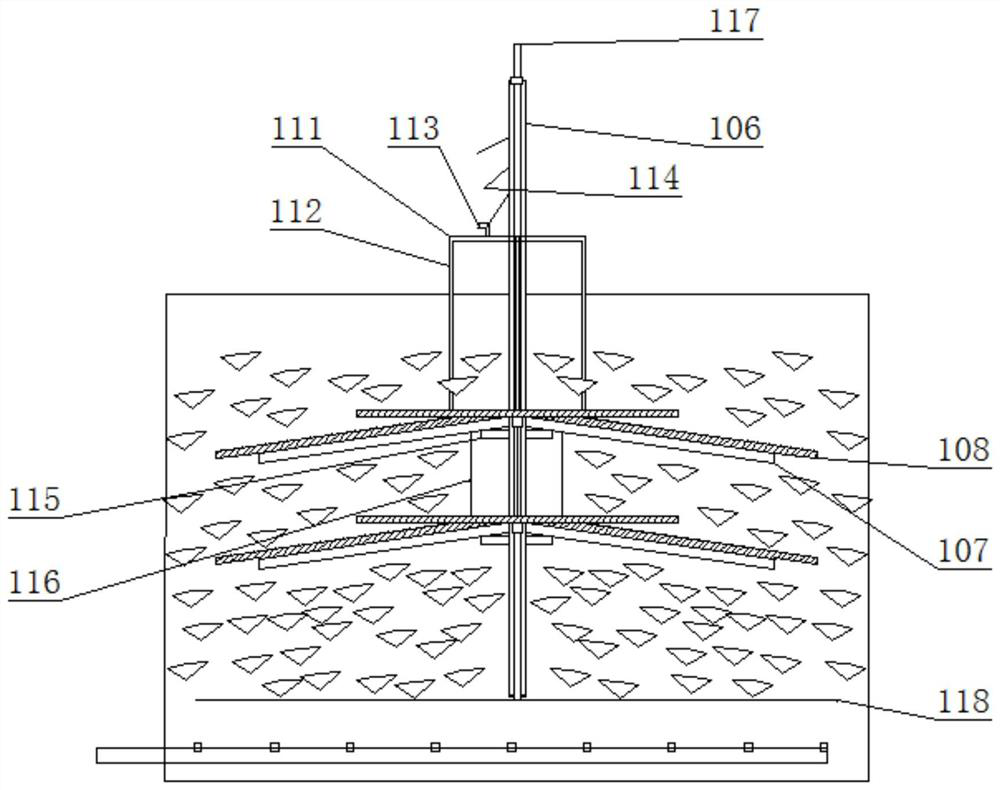

[0033] Such as Figure 1~6 As shown, the present invention provides a coal gasification wastewater treatment device, including a primary biofilm reactor 1 and a secondary biofilm reactor, and the primary biofilm reactor 1 includes:

[0034] The housing 101 has a hollow cavity inside;

[0035] The aeration device is composed of a gas pipe 102, a gas regulating valve 103, and an air pump 104. The first part of the gas pipe 102 is located at the bottom of the housing 101, and the first part of the gas pipe 102 is formed by a ring and is arranged in the ring. The rice-shaped branch pipe of the circle is formed;

[0036] Suspended filler 105, which is filled in the casing 101, and accounts for 65% of the volume of the cavity of the casing 101, and is located above the air pipe 102;

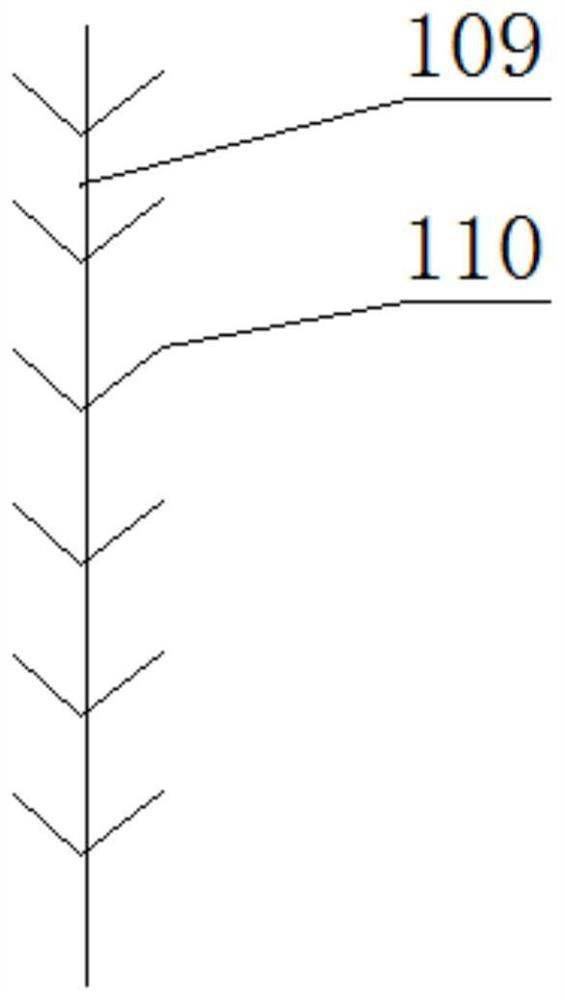

[0037] The desilting parts include main support rods 106, support rods 107, desilting nets 108 and pullers. The support rods 107 are arranged in two groups along the axis of the main support rods 106...

Embodiment 2

[0053] The first-level biofilm reactor and the second-level biofilm reactor of Example 1 are used to process coal gasification wastewater. The parameters of coal gasification wastewater before treatment are 1000mg / L for COD, 310mg / L for ammonia nitrogen, and volatile phenol≤185mg / L. The pH value is 7.4, the COD removal rate of the treated coal gasification wastewater is 89.2%, the ammonia nitrogen removal rate is 96.4%, and the volatile phenol removal rate is 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com